- Home

- Companies

- Industrial Waste Water Treatment ...

- Products

- IWAT - Chamber-filter-press Machine

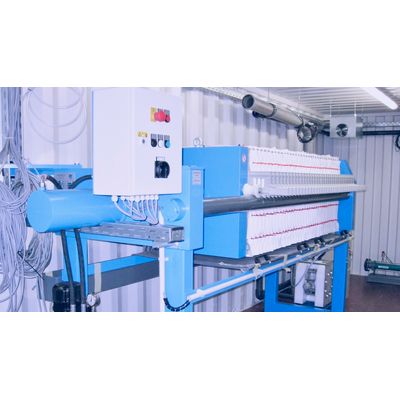

IWAT - Chamber-filter-press Machine

With high pressure for high dewatering efficiency – up to 60% dry solids content. Chamber filter presses are indispensable in industrial wastewater treatment and process water recycling, as they efficiently separate solids from liquids.

They operate on the principle of mechanical filtration, where sludge is pressed between filter cloths arranged in multiple chambers under high pressure. The solids form a filter cake while the clarified water drains away.

The main advantages of this technology are the production of a dry, landfill-ready filter cake, a significant reduction in sludge volume, and the possibility to recycle the filtered water.

These benefits result in lower disposal costs and more efficient water management, making the chamber filter press a valuable tool in industrial applications.

Principle of pressure flotation

- After the conditioned sludge has been pumped into the filter chambers of the chamber filter press,

- the water (filtrate) is pressed through the filter cloths at a pressure of up to 15 bar,

- The solids remain behind and form the filter cake, while the clarified water is removed through horizontal pipes.