SBM Micro Powder Technology

- Home

- Companies

- SBM Micro Powder Technology

- Products

- SBM - Model PEX - Jaw Crusher

SBM - Model PEX -Jaw Crusher

The jaw crusher consists of two jaw plates, a movable jaw, and a static jaw, forming a crushing chamber, which simulates the movement of the two jaws of an animal to complete the material crushing operation. It is widely used in stone mining, metallurgy industry, building material, highway, railway, water conservancy, and chemical industries. Various materials with compression resistance less than 320MPa can be crushed.

Most popular related searches

jaw crusher

material crushing

particle sizing

lubricant system

crushing system

water conservation

water conservation industry

building water

mobile crusher

water industry

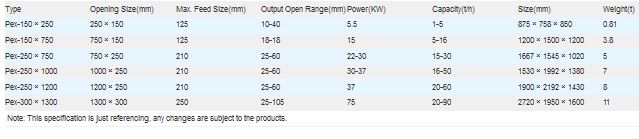

- Output Size: 25-105 mm

- Feed size.: 250 mm

- Capacity: 1-90t/h

Product features: Almost all minerals, such as quartz, feldspar, mica, calcite, gypsum, fluorite, limestone, soil, clay, marble, granite, pebble, coal, slag, iron ore, copper ore, manganeseore, refractory material, glass, etc.

- The working mode of PEX jaw crusher is mobile and extrusion. The working principle is as follows: The jaw crusher uses the motor as the powder. The eccentric shaft is driven by the wheels of the motor, the V-belt, and the grooved wheel so that the movable jaw plate moves according to the prescribed orbit.

- Therefore, the material in the crushing cavity which is composed of the fixed jaw plate, movable jaw plate, and the side backplate, can be crushed and discharged through the discharge port.

- When the jaw crusher is working, the movable jaw plate cyclically reciprocates against the fixed jaw plate, sometimes approaching and sometimes leaving.

- When approaching, the material is crushed by squeezing, splitting, and impact between the two jaws; when leaving, the crushed material is discharged from the discharge port by gravity.

- High crushing ratio, uniform particle size

- Point eclipse discharge opening adjustment devices, reliable and easy to adjust the range to meet the needs of different customers.

- Safe and reliable lubrication system, easy to replace parts, low maintenance workload.

- Simple structure, reliable function, low operating cost.