zhangjiagang pulier machinery co.,ltd/Hunan Jiangye New Energy Technology Co.,Ltd

- Home

- Companies

- zhangjiagang pulier machinery ...

- Products

- Jiangye - Circuit Board Recycling ...

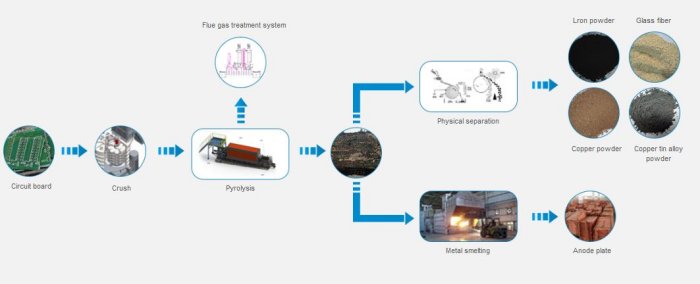

Jiangye - Circuit Board Recycling System

E-waste recycling equipment refers to the machinery and technology used to recycle electronic waste. The equipment may vary depending on the type and quantity of e-waste being recycled, but some common types of e-waste recycling equipment include: Shredders: These machines are used to shred electronic waste into smaller pieces, making it easier to handle and process. Separators: These machines separate different components of e-waste, such as metals, plastics, and glass, so that they can be recycled or disposed of separately. Refining systems: These systems are used to extract precious metals, such as gold and silver, from e-waste. Sorting machines: These machines use sensors and other technology to sort different types of e-waste based on their material composition. It's important to note that e-waste recycling equipment should be handled by trained professionals to ensure safety and prevent environmental damage.Most popular related searches

circuit boards recycling

e-waste recycling system

recycling system

e-waste recycling

waste recycling system

e-waste

waste recycling

process control monitoring

lithium battery recycling

e-waste sorting

- It has a wide range of applications, compatible with recycling of various types of circuit boards (including circuit boards with components).

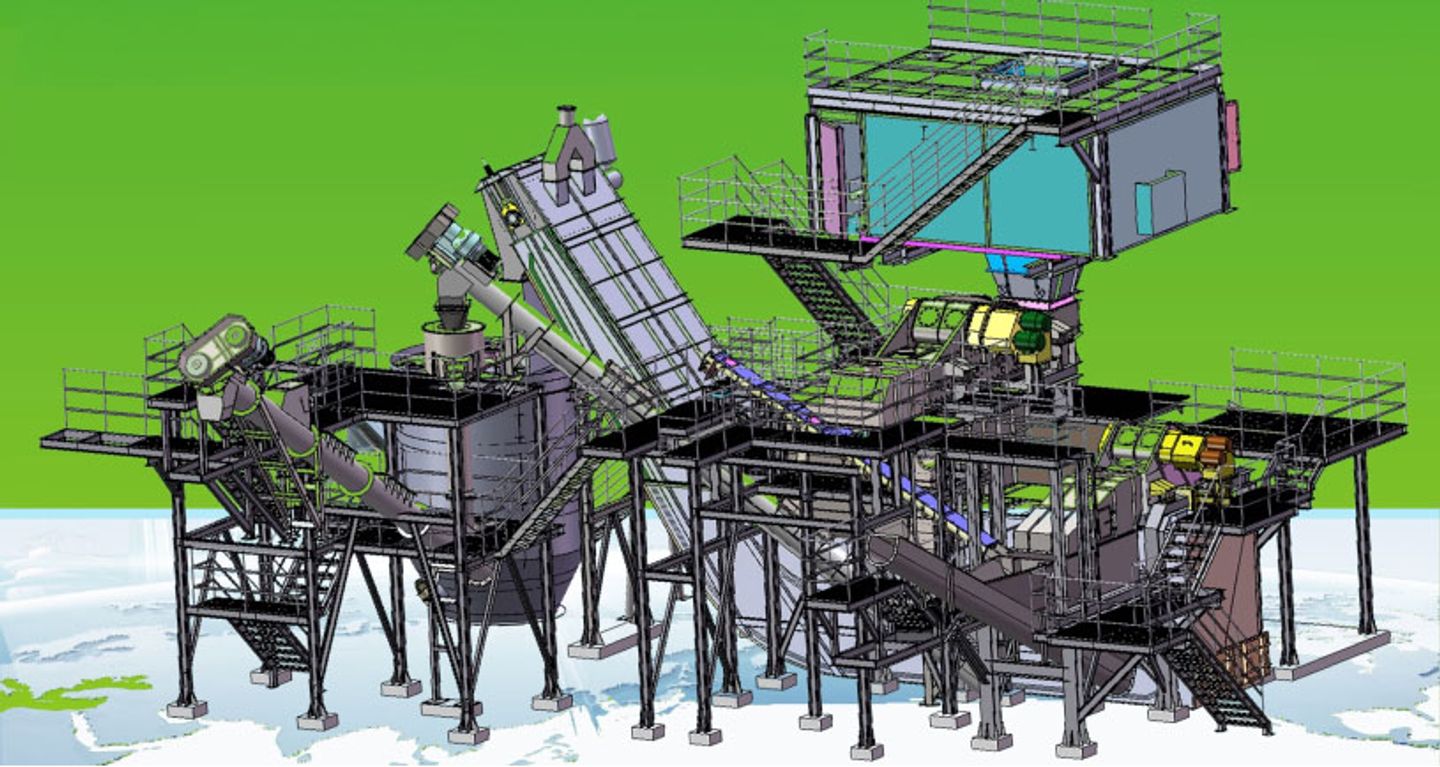

- The crushing system adopts unique two-stage open-circuit crushing technology and equipment to improve crushing efficiency and reduce maintenance costs.

- This system uses high-temperature pyrolysis technology to harmlessly treat organic components such as epoxy resin in the circuit board to dissociate metal and non-metal monomers to ensure physical separation.

- This system adopts the two combustion + quenching method to process the cracked gas, so that the organic gas in the cracked gas is fully burned, avoiding the production of dioxin, and the exhaust gas emission meets the requirements of GB-18484-2001.

- This system further separates copper and tin metals through self-developed surface active agents, and the separation efficiency of tin reaches 92%.

- The recovery rate of copper, iron, tin and glass fiber in the system is over 96%.

- The whole system adopts PLC+ upper computer control, which has a high degree of automation and has integrated functions such as on-site information collection, input, data processing, control, monitoring, alarm, protection, and communication. The associated operation of each unit ensures the safe and efficient production of the system.

- The system is equipped with a fire-proof and explosion-proof system to ensure safe production.