- Home

- Companies

- JP Recycling Ltd

- Products

- JP-Recycling - Plastics Recycling ...

JP-Recycling - Plastics Recycling Machines

The average consumer doesn’t think too hard about recycling. They’ll follow local guidelines for their plastics and consider it a job well done. Naturally, there’s much more to recycling plastics than meets the eye. Plastic recycling has always been a hot topic around the world. The most regularly recycled plastics are PET (polyethylene terephthalate), HDPE (high-density polyethylene), PP (polypropylene), and PVC (polyvinyl chloride). Some facilities are only able to recycle certain plastics and others can do them all. We’ll talk about the steps involved in getting plastics ready for recycling and the three types of recycling processes. Let’s take a closer look at the plastic recycling process.

Step 1: Collecting

Naturally, plastic needs to find its way to a recycling centre before the recycling process can begin. This is the step most people are familiar with. Sorting waste into the appropriate container makes up Step 1 of the recycling process and in involves morning run by the local authourities trucks to collect your bins. While it might seem easy, only 9% of plastic even makes it this far. Public education and city infrastructure haven’t yet solved the problem of ensuring the majority of plastic waste goes to recycling.

Step 2: Sorting

Before recycling can get underway, the plastic waste needs to be sorted according to its type. Plastic comes in a range of different varieties, such as PVC and PET. Each type of plastic has different properties and some are poor candidates for recycling. Sorting uses a range of different tools to isolate plastic by type to ensure a useable end result. Recycled plastics are first sorted by plastic type once they reach the recycling facility. This sorting is done either manually or by machines with the capability of sorting one plastic from another. These machines use anything from infrared to x-rays to recognize a polymer’s unique signature and sort plastic accordingly. If plastics are mixed in this stage of the process, the entire batch could be contaminated so it’s a very important step.

Step 3: Decontamination

A lot of plastic waste comes in the form of consumer goods. That means they may contain traces of food and drink, along with adhesive labels.Decontamination is exactly what it sounds like: washing the plastic to get rid of impurities. The end result of the recycling process should be as close to 100% plastic as possible to allow its reuse. Once the plastic has been decontaminated, it’s ready for the intense stages of recycling.

Step 4: Shredding Resizing and Identifying

The clean plastic is now shredded into smaller pieces, which allows further sorting. In this sorting phase, the plastic is filtered down further by a number of different categories. Machines test for density, thickness, and colour to establish the grade of the plastic and ensure that similar materials end up together. This creates a more useable end result. The next step is resizing the plastic into smaller pieces. This makes handling and processing easier in the long run and is performed by shredders and granulators which use industrial blades to cut and chop the plastics down into these manageable sizes. From there, the new plastic mulch is pushed through a screen and moved onto the next step. There are some facilities who stop at this step and sell the plastic mulch back to the industry.

Step 5: Wet Separation

At this stage, the recycled plastic is washed to remove everything from paper and glue to sand and grit. Water baths can be used to separate the plastics out by weight and water sprayers spray hot water over the plastics continuously. Chemicals and detergents can be added to get the plastics as clean as they can be before entering the next step.

Step 6: Dry Separation

There are a few ways plastics are dry separated. These include sorting them by thickness, applying heat to sort them by melting point, or exposing them to ultraviolet or fluorescent light separates them by color.

Step 7: Compounding

This is the final step for most recycled plastics which involves converting all the plastic mulch into high-quality, reusable pellets. This conversion is done by machines and the final result is a pellet that can be easily distributed and reused by the industry. There are also three types of recycling: Primary, Secondary, and Tertiary recycling and these are described below: Primary Recycling – Involves using recycled plastic to make a product similar to that of the original plastic. Secondary Recycling – A process where the product being made from the recycled plastic has different properties than the recycled plastic. Only segregated plastics can be processed with secondary recycling

Step 8: A New Beginning

Finally, the plastic is ready to recycle. Machines melt and crush the plastic into plastic pellets, turning it back into a raw material that manufacturers can use to create new products. The end result looks like a kind of large-grained sand. If everything has gone well, there won’t be any signs left of the plastic’s previous life.

Different Type of Plastic and Codes

What we think of as “plastic” covers the wide range of malleable, synthetic compounds we use on a daily basis. In truth, we come into contact with many different plastics, all with varied properties and applications. Most of us would struggle to name even one or two.

Below, we’re looking at some of the different types of plastic.

Polyvinyl Chloride (PVC) (C2H3Cl)n

Melting Point: 100 °C (212 °F) to 260 °C (500 °F)

For all the different types of plastic, PVC is the only one that approaches the status of household name. That’s likely because PVC has, for decades, seen extensive use in commercial and residential properties. It’s a popular option for windows, sidings, and pipes. It’s weatherproof, so it can take the place of traditional construction materials where there’s a desire for both weatherproofing and aesthetics.

PVC remains popular for now, but the jury is out on its future. The toxic nature of PVC is playing a key role in discussions about its future use, as is the difficulty of recycling PVC plastic.

Examples: Plumbing pipes and guttering, electrical wire or cable installation, shower curtains, window frames, and flooring.

Polyethylene Terephthalate (PET) (C10H8O4)n

Melting point: 260 °C

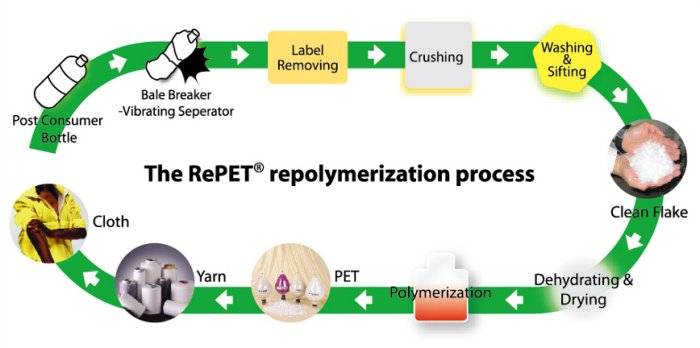

This for of polymer is even more ubiquitous than PVC, but also less well-known.You’ve almost certainly come into contact with PET at some point in your day. It exists in clothing, in plastic bottles, and flexible food packaging. PET can be shaped into fibres and films, which explains its popularity for use in malleable goods. JP Recycling is specialised in recycling mainly PET.

About 25% of PET bottles are recycled in the U.S. with the general idea that bottles made from PET should be recycled and not reused. The recycled PET is crushed into PET flakes and reused to make polyester fiber or new PET bottles.

PET plastic is also recyclable. Its almost universal use in plastic bottles makes PET plastic a popular material of choice for recycling companies.

Examples: Juice or squeeze bottles, Water, fruit juice and soft drink bottles, peanut butter jars, plastic film, and microwaveable packaging.

High-density Polyethylene (HDPE) (CH2-CH2)n

This form of plastic offers a high strength-to-density ratio, which makes it popular in industrial products. But this flexible material is just as popular in consumer goods. HDPE has made popularity gains in recent years as an alternative to the toxicity of PVC goods. Its applications are vast, ranging from bottle caps to food storage containers to plastic bags. Chemical resistant barriers like those used in landfill sites may also be made of HDPE.

However, only 30-35% of these plastics get recycled in the U.S. each year.

Examples: Shampoo containers, milk bottles, detergent bottles, and molded plastic cases.

Low-density Polyethylene (LDPE) –(CH2-CH2)n–

As HDPE’s cousin, LDPE shares many of its traits. However, it’s tensile strength and density are both lower. Moulded objects like containers, tubs, and trays are often composed of LDPE. Manufacturers also use LDPE where flexibility is a key consideration, such as in packaging foam and plastic wraps.

Examples: Garbage bins and bags, outdoor furniture, siding, floor tiles, shower curtains, and clam shell packaging

Polypropylene (PP) (C3H6)n

This form of plastic is the second most-produced commodity plastic after polyethylene. One of PP’s key traits is its resistance to fatigue. This makes it practical for use in any plastics with deformation built into their intended function. Plastic chairs and hinges on flip tops are two such examples.

PP is also heat-resistant, making it practical for use in laboratory and medical equipment. The Many Different Types of Plastic We live in a plastic world, so it’s easy to take the many different types of plastic for granted. Taking the time to learn about these different types can broaden your awareness of just how completely plastic permeates our lives.

Examples: Lunch boxes, take-out food containers, ice cream and yogurt containers, bottle caps, drinking straws, appliances, car bumpers, and plastic pressure pipe systems.

Polystyrene (PS) (C8H8)n

Melting point: ~ 240 °C (464 °F; 513 K)

PS can be recycled and reused but, while many recycling centers can recycle PS, they don’t. This is because the market for PS recycle material is not big enough for them or a local curbside service to get involved in. That has been changing in recent years, but PS still makes up 35% of landfill material in the U.S. Since it can possibly leach carcinogenic styrene into food products, PS should be avoided whenever possible. To do this, try reusable coffee cups, plastic cutlery, and stainless-steel takeaway containers.

Examples: Plastic cutlery, containers, foam cups for hot drinks and packing peanuts, compact disc (CD) and cassette boxes.

Others (HIPS,PES and ABS)

High Impact Polystyrenes (HIPS) – refrigerator liners, vending cups, and food packaging. Polyamides (PA) – fibers, tubing, fishing line, low-strength machine parts such as engine parts or gun frames.

Polyester (PES) – textiles and fibers

Acrylonitrile Butadiene Styrene (ABS) – electronic equipment cases and drainage pipe

What is Plastic Recycling?

When we talk about plastic recycling, we’re talking about turning plastic waste into new plastic products.

By sorting and processing plastic waste, the recycling industry can restore plastic goods back to usable form. These plastics would otherwise go to landfill, where they can take over 400 years to break down.

After recycling, plastic goods emerge as pellets that manufacturers can use to create new goods from either wholly or partially-recycled materials. This extends the useable lifespan of plastic considerably.

Why Do We Recycle?

The advantages of plastic recycling are numerous.

Every time we produce synthetic goods, we enter into a long chain of processing and transportation. This can use a vast amount of energy and contributes to the carbon footprint of heavy industry.

Recycling also gives us a chance to reduce the amount of waste that ends up in landfill — or worse, in the environment at large. Plastic pollutants aren’t just unsightly. They’re a threat to the animals they come into contact with. Plastic contamination of oceans and rivers may even pose a threat to humans in the long term.

What Can We Recycle?

There are many varieties of plastic, even though we use a blanket term to refer to them all. Of the many kinds of plastic, only some are fit for recycling.

It may sound like recycling can save us from a world of plastic, but 91% of all plastic is never recycled at all. Of that 91%, a vast amount is consumer-grade plastic that could go in household recycling bins.

Government and manufacturer initiatives are making it easier for consumers to know which plastics are recyclable. Most plastic packaging in the UK now contains recycling guidance.

Plastic Recycling Explained

We hope we’ve shed some light on the matter of plastic recycling. Educating yourself is one of the largest steps you can take toward doing your part to reduce the plastic threat. With a little knowledge, you can play your part in the recycling effort.

With all the hubbub around recycling,

it’s easy to focus on the process and lose sight of the purpose. While recycling was popular as recently as World War II, it took until the late 90s for the recycling of modern consumer goods to gain traction. But why is recycling so important? Why do we spend so much time and money to make it happen? Let’s look at a few key advantages of plastic recycling below.

Environmental Cleanup

We’re facing a plastic apocalypse. The same traits that make plastic such a useful material also make it an environmental disaster if we don`t recycle it. Plastic doesn’t biodegrade in the same way that food waste or natural fibres do. This problem is most obvious in the ocean. Vast amounts of waste plastic end up in the ocean from industrial processes or by way of litter. Sir David Attenborough, among many others, are doing their best to bring attention to this mounting problem.

Energy Conservation

The majority of plastics are synthetic and derived from petrochemicals. As a general rule, the longer the manufacturing process for a material, the more energy it takes to produce. The energy cost of producing materials has grown into a large concern, as even modern nations face an energy deficit. By recycling plastic, we can extend the plastic supply without the intensive process of manufacturing from scratch.

The industrial processes involved in producing plastic also contribute to CO2 emissions, so recycling can reduce the industry’s impact on climate change.

Waste Reduction

The world’s population now stands at over 7 billion. Within the next generation or so, experts say it’ll rise to 9.8 billion . Humans are messy creatures. The creature comforts we enjoy in modern civilisation come at the cost of staggering amounts of waste. Any waste we don’t recycle will go to landfill if it isn’t burned for energy — which itself contributes to CO2 emissions. The conclusion is obvious: the more the population grows, the more land we’ll need to dedicate to burying waste. Land used to bury waste becomes unfit for human habitation, even decades after the closure of a landfill site.

Why the need of Plastic Recycling

Plastics are durable, lightweight and inexpensive materials. They are able to be shaped and molded into a plethora of shapes and sizes making them one of the most versatile substances in the world. Every year, more than 100 million tons of plastic is manufactured across the globe. Out of this, 200 billion pounds is newly manufactured plastic being put into packages and products after being thermoformed, foamed, or laminated. Currently, about 50% of plastics are thrown away after only one use and Americans use 2.5 million plastic bottles every hour, which are just thrown away. Plastics account for 10% of the total global waste and, since they take hundreds of years to degrade, they are the number one killer of seabirds and marine mammals. On average, one million seabirds and 100,000 mammals are killed by the small pieces of plastic floating in the oceans. This, among other reasons, is why recycling is so important. Producing plastic from recycled plastic uses 88% less energy than producing new plastic and about 9.1% of new plastic production is recycled in the U.S. every year consisting of plastic packaging, plastic durable goods, and other non-durable goods. This 9.1% is small when compared to Europe who currently recycles 25% of their produced plastics.