- Home

- Companies

- Zhengzhou Kerui Industrial Development ...

- Products

- Kerui - Ceramic Fiber Insulation ...

Kerui - Ceramic Fiber Insulation Blanket

Ceramic fiber insulation blanket is an insulation material made of ceramic fibers. It is lightweight and has low thermal conductivity. It is a popular choice in high-temperature kilns. Kerui has exported this product to 50+ countries, including Russia, Indonesia, South Korea, Vietnam, Jordan, Pakistan, Iran, etc. We offer high quality standard and customized products to these partners.

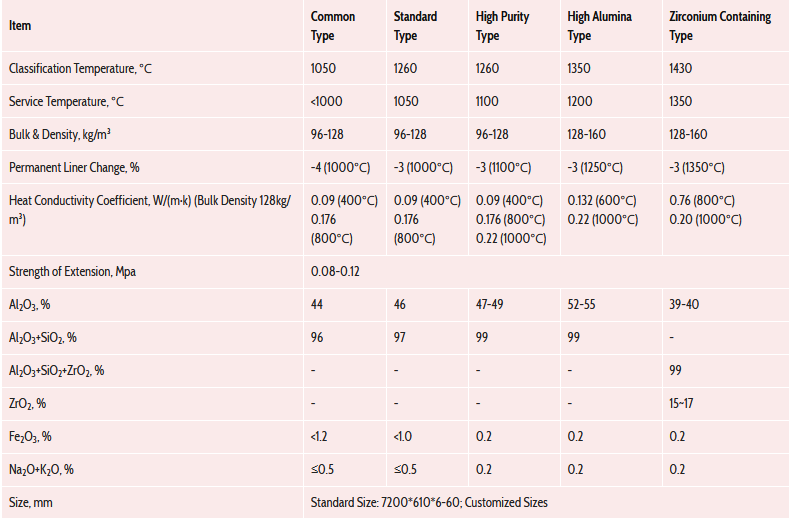

- Classification Temperature: 1050-1430ºC;

- Al2O3: 39-55%;

- Fe2O3: <1.2-0.2%;

- Bulk Density: 96-160kg/m³;

- Lenth: 7200mm/3600mm/Customizable;

- Width: 610mm/1220mm/Customizable;

- Thickness: 6-60mm/Customizable;

- Packaging: one roll/one bag, two rolls/one bag, one roll/one box;

- Shipment: 7-15 working days;

Ceramic blanket is an insulation material made of ceramic fibers through needling and other processes. The needling process interlaces the ceramic fibers to form a strong network structure. It can improve the performance of the insulation blanket, such as strength, wear resistance, thermal insulation, and so on.

Its main components are kaolin, alumina, and silica. These raw materials give the finished ceramic fiber blanket excellent thermal stability and high-temperature resistance. In addition to standard products, we support custom ceramic fiber blankets to meet the special needs of customers in the insulation industry. We also provide other insulation brick and insulation products. Consult us.

1000+ Partners Choose Kerui Ceramic Fiber Blanket

Our customers come from more than 50 countries, including Russia, the Philippines, Malaysia, Saudi Arabia, the United Arab Emirates, Oman, Morocco, and more. Many of our cooperative clients have chosen to work with us long-term. They have expressed high praise for our ceramic fiber insulation blankets and services. These partners include RUSAL, CHALCO, ALBA, POSCO, PSM, etc.

- Types: Common/Standard (STD)/ High Pure (HP)/ High Alumina (HA)/ Zirconium (HZ);

- Applications: It can be used for industrial kiln wall linings, storage tanks, high temperature pipelines, smelting furnaces and can also be used as modular or folded block processing materials.

- Industrial kiln wall lining;

- Backing materials;

- High-temperature pipeline insulation;

- Kiln masonry expansion seams, furnace doors, and top cover heat sealing;

- Module, folding block processing material;

- Fire parcel.

High Temperature Resistance

Ceramic fiber blankets can be used at temperatures up to 1430ºC. They can withstand high temperature working environments and maintain normal performance, extending the life of the kiln.

Good Thermal Stability

Ceramic fiber blankets will not deform structurally under rapid temperature changes. They have low permanent linear change. They provides protection for the kiln under thermal shock conditions.

Low Thermal Conductivity

The thermal conductivity of Kerui ceramic fiber blankets is low. The thermal conductivity is between 0.09-0.76 W/mK at 400-1000°C. This provides good thermal insulation for the furnace.

Strong Mechanical Properties

Ceramic fiber blankets have strong mechanical properties, such as tensile strength, wear resistance, tear strength, elasticity, and so on. This gives them good anti-deformation ability in the kiln, like ceramic fire board.

Chemical Corrosion Resistance

Ceramic fiber blankets have good chemical stability. They can resist most acidic and alkaline chemical erosion. In addition, they have good high temperature oxidation resistance in industrial applications.

Noise Reduction

Ceramic fiber blankets have a porous structure, high density and light weight. They can effectively absorb sound waves and block sound transmission. This can improve the high temperature working environment.