Kistler-Morse - Specialty Product Technologies

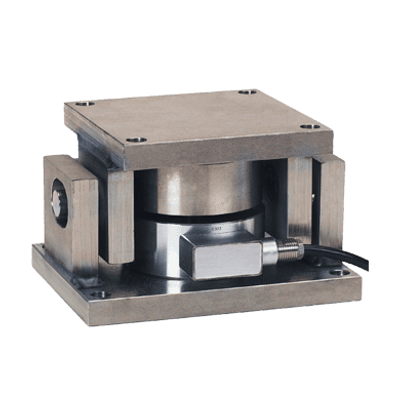

Kistler-Morse - Model LD3xiC -Load Disc Sensor

The High-Precision Process Expert: Up to 0.03% accuracy in dynamic content control through weight measurement, extremely robust design with cage. The LD3xiC Load Disc “Heavy Duty” Compression Weighing Systems dynamically measure the content level based on the container weight and precisely indicate even the smallest changes. The sensor is integrated in an extremely robust base housing, which compensates for e.g. static imbalances of the vessels and thermal expansion. This makes LD3xiC ideal for process, stirring and mixing vessels in food and industrial applications

Most popular related searches

load cell technology

mixing vessel

load cell

weighing system

load sensor

integrity monitoring

weight indicator

process vessel

dissolved oxygen monitoring

- Reliable, high-precision measurement even under alternating loads: Measurement accuracy up to 0.03% at loads from 11,000 lb to 22,000 lb

- Extremely robust: The sensor is integrated in a cage that compensates for movement and imbalances

- Flexible: Also for interchangeable vessels, e.g. ingredient containers

- Always precise: Unlike level meters, thermal or density changes do not affect the measurement result

- Can be relied upon: Kistler-Morse pioneered load cell technology. This is still the standard for load and content measurement

- Average Accuracy: 0,03 % of rated load (=3,3 lbs with rated load 11,000 lb)

- Operating Temperature: 14...104 °F

- Insertion Length: Stainless steel 1.4542 (17-4 PH 900), brushed surface

- Measuring range: 11,000...22,000 lb

- Available Versions: Compact | Remote

- Communication: 5...15 V DC Full-Bridge