- Home

- Companies

- KMZ Industries

- Products

- KMZ - Bucket Elevators

KMZ - Bucket Elevators

Bucket elevators are used widely both as part of the KMZ Industries grain elevator complexes and for the renovation of existing facilities. Modern materials and technologies ensure long service life and high efficiency of conveying equipment.

Structural durability and various lining options ensure long-term operation, while the availability of the ablast discharger, speed control device, off-track detector, backflow sensor and brake make the operation safe. The bucket elevators made by KMZ Industries are designed for transportation of loose goods to a height.

KMZ INDUSTRIES MANUFACTURES 2 TYPES OF BUCKET ELEVATORS:

- Bucket elevators installed inside the structure. Maximum height: 60 m. Production capacity: up to 800 t/h.

- Bucket elevators with service platforms installed next to the structure. Maximum height: 35 m. Production capacity: up to 200 t/h. Reinforced bucket elevator with design in compliance with European safety standards (equipped with ladders with a pitch of 6 m and rest areas). Differs by reduced steel consumption since no supporting external structures are needed.

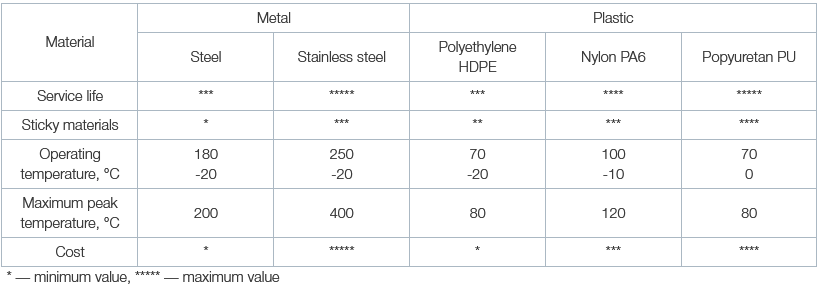

Our bucket elevators are equipped with metal or plastic buckets — depending on the customer’s wishes.

Regarding the complete own production set of bucket elevators, so here we also cooperate with the French company STIF. Buckets of bucket elevators produced by STIF`s have a patented form — this provides improved emptying performance of the moved product, which increases bucket elevators productivity in similar standard sizes with competitors.

In metal buckets, the bent edge less injures the transported product, which reduces the percentage of combat. The geometry of the buckets contributes to uniform wear (after all, there are no places-stress concentrators) and minimizes sticking/retention of the product in bucket.

DISTINCTIVE FEATURES OF THE BUCKET ELEVATORS ARE AS FOLLOWS:

- bucket elevators are produced out of S350GD high-strength galvanized steel from European manufacturers;

- durable structure for continuous operation;

- maximum height — 60 meters;

- high wear-resistance of traction device (belt and buckets);

- gravity or screw take-up of the drum;

- ease of maintenance.

- Prolonged service life

- Design compatible with any kind of automation system

- Monitoring systems minimize interference by staff

- Selection of energy-saving drivers (up yo 30% of resource saving)

- System of electro/explosion/vibro/environmental security

- Convenience of maintenance and repair

- Minimum percentage of damaged grain

- Polymer rollers for noise minimization (optional)

- Maximum sealing of joints

- Various options for casing lining

- Bearing assemblies from leading European manufacturers