- Home

- Companies

- KMZ Industries

- Products

- KMZ - Model TSC - Chain Conveyors

KMZ - Model TSC -Chain Conveyors

Chain conveyors are designed for horizontal and horizontal-inclined transportation of grain crops. TSC conveyors have a reliable industrial design and are able to work under severe and sustained loads.

The conveyor’s chain is made of special steel and ensures continuous long-term operation. The British company JOHN KING supplies chains for our conveyors. The production is equipped with a fully robotic line, with 100% quality control at every production stage. In addition, JOHN KING chains have improved technical characteristics, energy efficiency, high reliability and long service life.

Use of polyurethane scrapers ensures low energy consumption, reliability, and longevity of the traction device along with reduced damage to the product being transported and low level of noise from the operating equipment. The conveyor is covered in full, which prevents the emission of dust.

Figure: 1 – feed pit conveyor with sections of the receiving hopper.

Distinctive features of the conveyors are as follows:

- high capacity and simplicity of maintenance;

- high wear-resistance of the traction device (chain and scrapers);

- minimum dust discharge into the atmosphere during the product’s transportation;

- possibility to unload the product along the transportation route;

- models made of galvanized metal are available;

- made of high-strength galvanized steel with coat 275 g/m2 from European manufacturers;

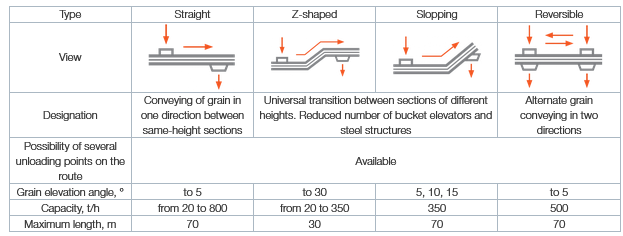

- various transportation routes: straight, z-shaped, slopping, reversible.

Protection lining

We offer chain conveyors:

- with lining;

- without lining.

Chain conveyors are lined to increase their service life by eliminating the wearing of their structures. The protected parts typically include the bottom and, if necessary, side walls to the conveyed product level. The lining sheet material is bolted. We select the optimal lining material taking into account the features of the conveyed product.

- Prolonged service life

- Design compatible with any kind of automation system

- Monitoring systems minimize interference by staff

- Selection of energy-saving drivers (up yo 30% of resource saving)

- System of electro/explosion/vibro/environmental security

- Convenience of maintenance and repair

- Minimum percentage of damaged grain

- Polymer rollers for noise minimization

- Maximum sealing of joints

- Various options for casing lining

- Bearing assemblies from leading European manufacturers

- Ease and speed of assembly