Komline-Sanderson

Komline-Sanderson - Plunger Pump

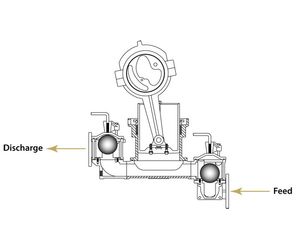

K-S Plunger Pumps are engineered for heavy duty service in difficult sludge, slurry, float transfer, or metering applications. It is a self-priming positive displacement pump that can pass solid objects up to 1-5/8" in diameter, rags, or entrained air. Our pumps have capacities to 34 liters per second (540 gpm) at heads to 90 meters (300 feet). K-S has pump installations that are over 55 years old.

Most popular related searches

plunger pump

self-priming positive displacement pump

industrial wastewater treatment system

primary sludge thickening

food waste processing

food industry waste

wastewater treatment system

industrial wastewater treatment

positive displacement pump

belt filter press

- Self-priming

- Can pump viscous fluids

- Can run dry

Move heavy solids laden sludges typically found in municipal and industrial wastewater treatment systems.

- Primary sludge

- Thickened Sludge

- Waste activated sludge

- Sludge transfer

- Belt filter press feed

- DAF float

- Scum

- Pulp and paper stock and pulp wastes

- Food processing wastes and slurries from grains, fish, meat packing and cannery operations

- Oil field production and refinery sludges

- Self priming with ability to handle suction lifts and entrained gases

- Positive displacement

- Can run dry without damage

- Flow rate is not system head dependent

- Flow rate is not sludge concentration dependent

- Positive metering

- High volumetric efficiencies, 90% and higher

- No critical tolerances

- Flow rate consistent throughout life of pump

- Easy clean out capability

- Large internal clearances

- Handles high solids concentrations

- Built-in overload protection

- Low cost of maintenance

- Common replacement parts are easily accessible

- Units are available as simplex, duplex, triplex and quadruplex designs for flow rates up to 550 GPM and heads up to 300 ft.

- Constructed of heavy duty 30,000-40,000 close grained iron which enables operating pressures up to 130 psi and hydrostatic test pressures up to 200 psi

- Fully sectionalized design for easy repair and replacement of parts

- Adjustable eccentrics for altering stroke length and providing overload protection

- Rigid 2" base plate design with 12" bearing pedestals which greatly reduces maintenance time involving alignment

4-bolt roller bearings for greater bearing- fe and strength

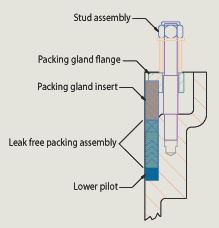

- Patented “Leak Free” packing designed to eliminate or drastically reduce the leakage commonly associated with plunger pumps.

- K-S introduced the separate and replaceable eccentric liners which reduce cost and maintenance time

- Hardened cast iron plungers available as standard with harder ceramic coatings and tungsten carbide coated plungers available for the most severe applications.

- K-S exclusive direct drive cycloidal arrangement that eliminates backlash commonly associated with other gear boxes or drive arrangements

- Valve chamber with easily accessible valve seats of cast iron, stainless or rubber construction

- Our KSK design is ideal for areas where space is- mited. 18" is the maximum width when the pump is set up in an in-line arrangement.

- Automated lubrication systems involving either an electric solenoid oiler or a shaft driven, mechanical force feed oiler.

- Mechanical or variable frequency speed control