Kopay Enviroment Technology

- Home

- Companies

- Kopay Enviroment Technology

- Products

- Kopay - Model KPDAF - Dissolved Air ...

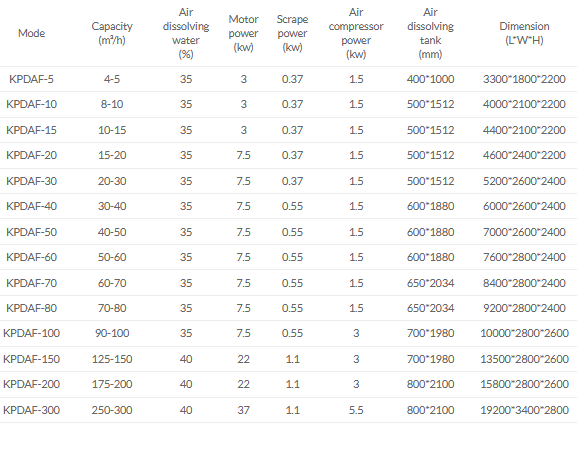

Kopay - Model KPDAF -Dissolved Air Flotation (DAF) System

Dissolved Air Flotation (DAF) systems are essential solid-liquid separation equipment widely used in the sewage treatment industry. They effectively remove suspended matter, colloid, oil, grease, and rubber substances during preliminary treatment of sewage. DAF aims to separate fine suspended solids, algae, and micro-floc from water, making it ideal for various industries including:

Most popular related searches

dissolved air flotation

dissolved air flotation system

DAF system

air flotation

air flotation system

organic wastewater treatment

solid-liquid separator

sewage treatment industrial

sewage treatment industry

solid-liquid separation

- Waste oil or grease separation and recycling in oil exploration and refining, biodiesel production, machining, and food production.

- High concentration organic wastewater treatment in paper, printing, dyeing, textile, leather, pharmaceutical, and fermentation industries.

- Biochemical effluent liquid separation including anaerobic and aerobic processes like activated sludge, contact oxidation, and filtration.

- Treatment of wastewater from farms and slaughterhouses including cattle, pigs, chickens, and slaughterhouse wastewater.

- Management of manufacturing waste from electroplating, painting, and similar processes.

- Purification of rivers, landscapes, and recycling water systems. Explore the versatility and efficiency of DAF systems for your wastewater treatment needs.

- Extremely high srcaping speed (2-3 times faster than conventional design) and safty operation because of using fully reverse and closed scraper.

- High hydraulic load and low footprint because of horizontal plates in the separation zone, more effective separation and optimization hydraulic flow in the separation area.

- Better outlet water quality because of W-shape sludge sedimentation hopper.

- Effectively minimize chemical consumption because of re-flocculation performance of reverse scraping design

- No blind angle in scum collection chamber.