Users of conventional universal display units can have difficulty in making use of their device´s options menu. Special applications require many more functions that are often not available with conventional units.

KRAL BEM 500 electronic unit enhances the KRAL Volumeter performance.

- Two-channel, i.e. differential measurement.

- Temperature and pressure pulse compensation.

- Measurement conversion.

- 7 point linearization.

- Limit value for a relay output, i.e. regulation of a bypass valve.

- Threshold value for signal suppression.

- Clear and easily readable display.

- Accurate handling by the use of a clear menu structure.

- Multiple mounting options. (KRAL Volumeter, wall, pipe, control panel).

The high-performance KRAL electronics BEM 500 has been developed further into the new Version 3 by our engineers with know-how and enthusiasm. Read the highlights of the innovation here.

Users of conventional universal display units often cannot make use of their device`s options. There is often a lack of functions that are important for special applications.

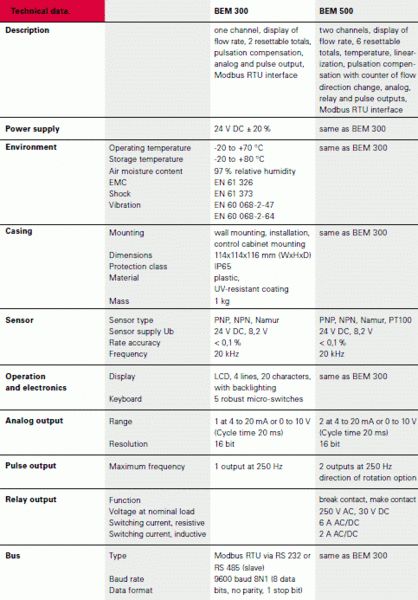

KRAL electronics BEM 300 and BEM 500 aid in the performance of KRAL Volumeter. The high quality electronic components and evaluation algorithms used, maintain precisely measured flow values to be shown on the display as well as the signal outputs. The BEM 500 uses KRAL calibration values for linearization. Temperature differences and liquid pulsations which can falsify the readings are corrected.

A display unit must supply the required information and assure accurate operation.

The KRAL BEM 300 and 500 always display the measured flow values with their units. The display is clear and very easy to read. There is a choice of four languages. KRAL sets up the units, the calibration factors and the density tables to meet customer specifications. If you need to make changes, an easy to follow menu is available including configuration software for PCs. Contrast and brightness are adjustable.

The BEM 300 and 500 protect KRAL Volumeter and the customer`s installation.

The flow and temperature ranges of the flowmeters are stored in the electronics and if values are exceeded then alarms are displayed. A bypass relay can be activated using flow rate limit value. The function of the temperature sensors is monitored. Knowing the temperature, the flow volume, the flow direction and the consumption assures the integrity of the installation.

KRAL provides special PC software for data capture, storage and evaluation as an option. Measured values can be stored for longer periods and evaluated at a later date. Immediate data analysis allows instant result of set-up and installation.

Universal signal forwarding includes scalable analog and pulse outputs, as well as a Modbus RTU interface.

Additional displays can be connected for remote indication.

Display: 76 x 25 mm LCD, contrast and illumination software-adjustable.

Keys: 5 robust micro-switches.

Measured value: Total, flow rate, accumulated total.

Units: SI, UK or US units. Total, rate as volume or mass. Temperature, density.

Signal forwarding: Scalable 4 to 20 mA or 0 to 10 V analog outputs, scalable pulse outputs, Modbus.

Power supply: 24 V DC.

Environment: Protection class IP65, robust plastic casing. Operating temperature -20 to +70 °C.

Mounting: In the control cabinet, on the flow measuring device, wall mounting or on the piping.

Advantages of the BEM 300.

- Low-cost version.

- Simple basic functions for precise flow measurement.

- Pressure pulse compensation.

- Mass calculation with constant density.

Advantages of the BEM 500.

- Temperature compensation.

- Pressure pulse compensation with counter of flow direction change.

- Two-channel, e.g. for differential measurement.

- Mass conversion and density tables.

- 7 point linearization.

- Limit value for a relay output (bypass valve).

- Threshold value for signal suppression.