Kuzeyboru - HDPE Corrugated Spiral Pipes

HDPE Corrugated Spiral Pipes which is described as the world`s best drainage pipes wit Larger Diameters of Corrugated pipes are three layers which supports each other and it standard is DIN 16961. With all the features shared by all commercially available plastic tube, and both the resistance and the metal reinforcement is slightly more inside a pipe. Used for many years in Europe helical corrugated pipes of thermoplastic tape spirally in a special machine from extrudate of the desired diameter are manufactured by winding shape and length. Inner surface of the HDPE Corrugated Spiral Pipes is smooth, the outer surface is profiled. Contribute to the metal layer provides extra strength in the profile of HDPE Corrugated Spiral Pipes.

Corrugated Metal Reinforced Spiral Wrap has based its feature and function of each floor in the HDPE Corrugated Spiral Pipes. Corrugated Spiral Pipes, smooth inner surfaces, outer surfaces are made so that the profile on Larger Diameter Corrugated Pipes.

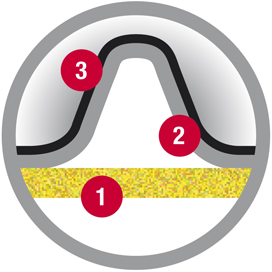

The structure of the three layers is as follows;

- Inner Layer: The inside layer of the HDPE Corrugated Spiral Pipes. Fluid passes through the liquid layer. High Density Polyethylene (HDPE) are produced from the material.

- Middle Layer: this section is the section which provides the strength property pipe. Given special profile shape steel strips previously coated with adhesive material used.

- Outter Layer: The outside of the pipe is protected against all kinds of parts for printing and strength.

2mm thick high density polyethylene (HDPE) made while using material. In relation to the effect of UV rays from sunlight is not affected by participating in the carbon black.

Application Area of HDPE Corrugated Spiral Pipes

HDPE Corrugated Spiral Pipes are described below uses for Larger Diameter Corrugated Pipes;

- Infrastructure application

- In the irrigation system

- Sewer lines and residential connections

- Rainwater

- Drainage systems

- Treatment plants

Metal Reinforced HDPE Corrugated Spiral Pipes Advantages

Due to the high strength of ribs more strength, corrosion resistance because with polyethylene, HDPE Corrugated Spiral Pipes can be transported easily and with a lifetime of 50 years and is an attractive and laying pipes in a short time.

- Due to the high density polyethylene contains raw shows high resistance to corrosion.

- On that load is more resistance to compression loads and prevents scattered uniformly on the tube.

- HDPE Corrugated Spiral Pipes has more than 50 years of life against environmental impact.

- Plastic show less resistance to fluid flow is smooth and fluid with an occupancy rate of more fluid. This is a sub-diameter group pulls down the project cost by selecting the project.

- HDPE Corrugated Spiral Pipes loss to be experienced during the application is not in question. Furniture and early binding process is easy.

- Application of HDPE Corrugated Spiral Pipes is easy and installation time is short, and labor costs are low. Construction equipment level is reduced to minimum.

- Puncturing the HDPE Corrugated Spiral Pipes with a high wear resistance because of the fluid and soil and damage our wealth infrastructure is concerned.

- During printing will occur on the ground than it prevents breakage of yawning fully inward.

- Break with earthquakes and other ground motions can not be disabled.

- Rivers, lakes and seas is no harm in using the link.

- Maintenance of HDPE Corrugated Spiral Pipes, operating costs are very low.

- Does not require special flooring material.

Laying Pipe Cost + Cost is the lowest kind of price.

Metal Reinforced HDPE Corrugated Spiral Pipes Testing and Test Procedure

In the manufacture of HDPE Corrugated Spiral Pipes to be used in raw materials and other materials that must be used and, after passing through a number of tests. Tests to be performed through during production engineers will increase the quality of production. TSE and ISO standards are appropriate to test these tests; These tests are ;

- Ring Stiffness

- MF Test

- Impact Resistance Testing

- Density Test

- Elongation Test

- Durability Test with Heat

- Leakage Test

- Length of Elongation Test

Metal Reinforced HDPE Corrugated Spiral Pipes Production in Larger Diameter Corrugated

Raw Materials Used Metal Reinforced HDPE Corrugated Spiral Pipes is High-density Polyethylene [HDPE HDPE]

In production of HDPE Corrugated Spiral Pipes, Polyethylene (PE) is quite robust and can be used in a wide variety of products softened, semi-permeable, and a white thermoplastic. From the ethylene monomer to form the name. Polyethylene is produced using ethylene. The most preferred that the products associated with detailed information about Polyethylene HDPE Pipe and Fittings page, RAW MATERIAL OF POLYETHYLENE find all the details about the polyethylene under PIPE title and the formation of high performance compared to other raw materials species in their field and as the economy as due to the long lasting strength until you can find a detailed information about the use of time. Interior of the HDPE Corrugated Spiral Pipes; It is a smooth-surfaced tube designed to carry the fluid and the ribbed outer layer is made of rib layer consists of two layers. This is molecularly bound to each other between two layers. Ratio of high density polyethylene for pipes according to the characteristics which will start production HDPE Corrugated Spiral Pipes and is adjusted by the steel strip. The surface of the steel strip is glued to wait as before. This steel band profile has been given shape by passing through pressure rollers to give shape reel tapes we use in attaching profile. Where as the steel strip gets into the circular shape to the slope of the line after the molding process of HDPE Corrugated Spiral Pipes. In this way, also ribs pipe is formed. HDPE Corrugated Spiral Pipes is the same as the subsequent steel strip production rate spacing. The absence of any interruption during production to continue providing the same quality as the same product. Coated with polyethylene prior to spiral winding steel bands are measures to be taken against corrosion. Steel bands, surface cleaning is performed after the slicing different for each diameter and coated with a special adhesive material out of the extruder.