- Home

- Companies

- Gemco Energy Machinery Co., Ltd.

- Products

- Gemco - Model BPM - Large Feed Pellet ...

Gemco - Model BPM -Large Feed Pellet Machine

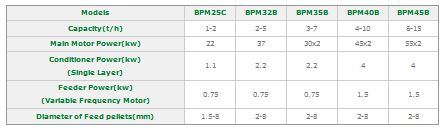

The most suitable complete 2-5 T/h pellet project is your best choice. GEMCO offers you diversified choices. If you are planning to build your own wood pellet plant, we strongly recommend that you choose this project, since: this is the most popular pellet production configuration.

The Structure and Operation of the Feed Pellet Machine

The feed pellet machine is mainly composed of feeder, modulator, pelleting machine, lubrication system etc. The operation procedure requires the degree of the material mixed with powder should be not over 15 %. The material enters into the feeding auger through the stock bin. By adjusting the step-less speed regulating motor to change the speed, the material can flow moderately. Then the tempering begins through the paddle agitator mixing with the steam. After the tempering, the temperature of the material can be 64℃ to 84℃, and the humidity can be 14% to 16%. At last, the material enters into the pressing box to be pelletized through the chute.

- The all-stainless steel feeder, configured with original import frequency converter to control, feed evenly and accurately.

- The all-stainless steel modulator, guaranteeing the efficient contact between the steam and the fodder, is configured with access hole with opening door to be cleaned and maintained easily.

- Double-motor drive. The high strength SPB narrow V-belt drive transmit stably and reliably with low noise.

- The feed machine is configured with many kinds of ring dies with different aperture diameters in a range of 1.5mm to 12 mm and compression ratio for different requires of different clients.

- The ring die of feed machine with quick-release coupling can reduce the time of replacing the ring die to improve the production efficiency.

- The modulator with major diameter is equipped for ripping the material fully to make the material smoother and make the pellet hardness more proper. The briquetting ratio can reach 98%. Also the abrasion to the machine can reduce to the lowest.