Aligned Vision

- Home

- Companies

- Aligned Vision

- Products

- Aligned Vision - Model LASERVISION-AI - ...

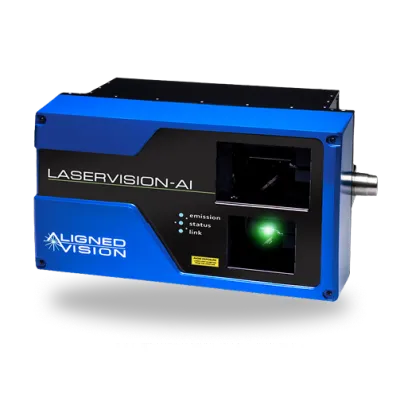

Aligned Vision - Model LASERVISION-AI -Large-field AI Inspection System

FromAligned Vision

LASERVISION-AI is the only large-field AI inspection system of its kind. It ensures your builds precisely match your designs—minimizing costly rework or scrapping. LASERVISION-AI`s laser projector works like an automated version of a presenter`s pointer, directing operators to the location of any anomaly.

Most popular related searches

- In-process automatic inspection.

- Detailed features located and inspected anywhere in a giant field of view.

- AI-enabled image analysis.

- Real-time laser feedback guides operators to anomalies.

- As-built digital twin automatically populated.

- Integration-ready for Industry 4.0.

- Size : 22″ x 11.5″ x 11″ / 56 x 29.5 x 28 cm

- Weight : 54.5 lb / 25 kg

- Beam Color : Green (532 nm)

- Laser Line Width : 0.02″– 0.075″ / 0.5 mm–2 mm

- Projection Angle : 60° (± 30°)

- Accuracy : ± 0.01″ / .025 mm

- Inspection Range : 3″ -50″ / 1m-15m

- Projection Range : 3″ -50″ / 1m-15m

- Minimizes idle time—automatically performs inspections in seconds without operator intervention.

- Eliminates human distraction, fatigue and expectation bias.

- Operates during production—doesn`t interfere with other production equipment.

- Greatly reduces rework & scrap.

- Verifies in real time and flags FOD, misalignment (reinforcing fiber, adhesive beads), out-of-spec edge locations, out of tolerance fiber orientation, and other flaws for immediate correction.

Automatically populates electronic documentation and generates the as-built Digital Twin, including-

- Calibrated images of every WIP surface.

- All nonconformances and any corrective actions.

+Feeds deep learning and closed-loop manufacturing improvements:

- Quantifies uncertainty

- Enables tighter allowables and less overdesign

- AI-enabled application development.

- Ongoing support for the life of your LASERVISION-AI system from our team of industry experts.