- Home

- Companies

- Weizhong Magnetics Co., Ltd

- Products

- WZ Magnetics - Model NdFeB - Large ...

WZ Magnetics - Model NdFeB -Large Heavy Duty Rubber Coated Magnets

Large heavy duty rubber coated magnets can be also called heavy duty mounting magnets. They are specially designed rubber coated magnet to mount heavy duty objects to replace the traditional mounting solutions of drilling or welding. Our heavy duty rubber coated magnets are in rectangular shape and they contain a sandwich magnet assembly or a U profile channel magnet assembly inside the rubber coating. These are the best structures to maximize the magnetic force.

Large heavy duty rubber coated magnets can be also called heavy duty mounting magnets. They are specially designed Rubber Coated Pot Magnets to mount heavy duty objects to replace the traditional mounting solutions of drilling or welding.

Types of Large Heavy Duty Rubber Threaded Magnets

Our heavy duty rubber coated magnets are in rectangular shape and they contain a sandwich magnet assembly or a U Profile Channel Magnet assembly inside the rubber coating. These are the best structures to maximize the magnetic force.

Traditionally, people mount objects either by drilling holes or welding, but drilling holes through the steel plate reduces its mechanical strength and creates opportunities for metal fatigue and corrosion, which can sacrifice the integrity and safety of the equipment. Welding brackets directly to the steel plate requires skilled labor. Both solutions increase overall construction time and cost. By using our rubber coated super magnets, you will have easy access to great flexibility and high efficiency. No welding, no drilling, no screwing, easy operation. You can easily mount it or remove it quickly without damaging the construction.

Heavy duty rubber coated magnets are versatile tools used in a variety of different applications. They are made with Rare Earth Magnets, which provide a strong pull force allowing them to lift heavy objects. The heavy duty magnetic materials are covered with a nickel plated and rubber covering surface for extra protection, making them more powerful and durable than other traditional magnets. With the proper care, these strong magnets can last for many years and provide the perfect solution for difficult jobs that require powerful magnets.

Applicaitons of Large Heavy Duty Rubber Coated Magnets

Fixing The Large Heavy Duty Rubber Coated Magnets

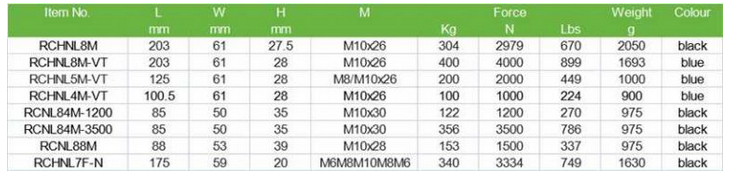

One of the top seller heavy duty rubber coated magnets is RCHNL84M. It is coated with black TPV rubber material and the mounting thread is a M10x30 stainless steel male thread. This magnet is 85x50x35mm in size, but its vertical holding force is up to 3500N thanks to its unique design. It has a sandwich magnetic assembly inside and the working surface is exposed without rubber coating, so the two pole legs where the magnetic fluxes concentrated can contact directly with the attaching surface.

Besides we also have lower force version of 1200N and fully rubber coated version in 1500N with the same overall dimensions to cater to your different applications.

Another best seller heavy duty rubber coated support magnet is RCHNLxxM-VT. This series is a U profile channel magnet assembly fully encapsulated by a layer of blue EPDM rubber coating, For which with a stainless-steel threaded stem on top. They are available in three sizes, with vertical holding force ranging from 1000N, 2000N to 4000N. More importantly, RCHNLxxM-VT have very good shear force performance and are perfect to hang heavy objects in shear direction.

TPV and EPDM rubber material feature great long-term ageing, anti-corrosion, UV-proof and anti-oil properties. So no need to worry about the quality even for a long period of applications in harsh working condition.

These powerful and strong magnets have an incredibly high pull force, making them ideal for lifting magnet applications. Nickel plated rubber covered heavy duty magnetic systems are very popular due to their flexibility and durability. They provide reliable performance in large heavy duty magnets lifting operations and can be used in extremely challenging environments.