- Home

- Companies

- LightManufacturing

- Products

- Light Manufacturing - Solar Rotational ...

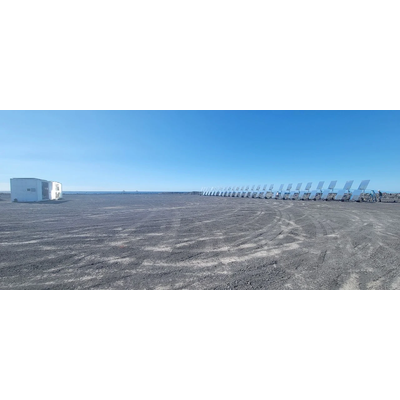

Light Manufacturing - Solar Rotational Molding System

LightManufacturing Solar Rotational Molding systems make large plastic products like water tanks without burning fossil fuels. This reduces the product cost and eliminates greenhouse gas emissions. The factories can be deployed to any sunny area, and do not require any infrastructure (no grid-energy connection).

Our solar plastic molding systems use free solar heat from heliostats instead of expensive fossil fuel to make plastic parts. Our Solar Rotational Molding (SRM®) factories are complete systems – just add molds and plastic. Energy for mold rotation is supplied by integrated photovoltaic panels, and heat is supplied by the LM heliostat array. Our molding process emits zero greenhouse gasses, and elminates energy costs (15-30% of typical rotomolded product total cost).

Because our molding systems install on bare ground (no infrastructure or utilities required), they can be located close to customer to reduce product shipping cost and associated emissions.

Models

- Lab System: 10L tank molding capacity

- SRM1: 2000L tank molding capacity, one armature

- SRM2: 2000L tank molding capacity, two armatures

- SRM3: 4000L tank molding capacity, two armatures

- SRM4: 8000L tank molding capacity, two armatures