- Home

- Companies

- Liming Heavy Industry (Shanghai)

- Products

- Liming - Model PF Series - Impact ...

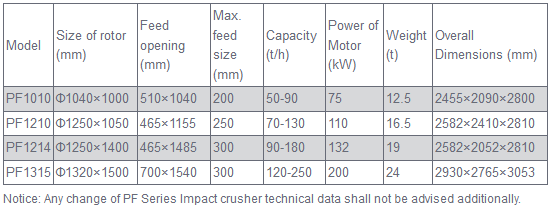

Liming - Model PF Series -Impact Crusher

PF Series Impact crusher is the latest product researched by our company by absorbing advanced technology at home and aboard and combining specific industry and mining condition in sand and stone industry. The discharging size of our PF series impact crusher is adjustable and the crushing specification is diversified. Users can adjust the gap between hammer head and impact plate and matching parts as needed to get perfect outputting size.

Impact crusher crushes material by striking energy. When it works, the motor drives the rotor rotates at a high speed, on which the blow bar is installed. As soon as the material get into the affecting area of the blow bar, they will be stroke by the blow bar and be thrown to the impact devices around the rotor. The high speed forces the material to rebound from the impact liner to the area where the blow bar effects until they have been crushed to the required size. The clearance between the impact racks and the rotor can be adjusted to change the size and shape of the end products.

- With the big feed opening and spacy crushing cavity, the impact crusher is suitable to crush bulky materials with a large capacity.

- Gap between impact plate and hammer can be conveniently adjusted to effectively control outputting size. Finished product is cubic and in good shape.

- Compact structure, strong rigidity, rotor has big inertia moment.

- High chromium flat hammer, impact resistant, wear resistant, small mechanical wear, huge impact force.

- Adoption of new rotor increases impact force.

- Complete crushing function, high reduction ratio, high productivity, low energy consumption and high comprehensive benefit.

- Non-key connection, simple structure, convenient maintenance, economical, reliable.

Impact Crusher for the highway construction

Urban road construction brought us tremendous changes. Highway and road construction, a great need for a complete stone production line to provide sources of protection. Moreover, the time when the demand is greater is even more important. Impact Crusher is suitable for processing side not exceeding 500mm, not more than 350MPa compressive strength of various coarse, medium and fine crushing.

Impact Crusher is used in ballast crushing plant

First, stones are crushed by ballast crusher into small size. Then the suitable ballast is screened out by vibrating screen, while unsuitable ballast returns to the crushing plant for crushing again. Impact crusher is a new type of high-efficiency crushing equipment. Being simple, reliable and energy-efficient, our impact crusher is one of the most frequently used rock crushers. It can crush materials of all hardness, being an ideal piece of equipment for secondary crushing.

Used in the crushing process of gypsum

The big raw gypsum is fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for the primary crushing. After first crushing, the material will transferred to the impact crusher by belt conveyor for secondary crushing; the crushed materials will then transferred to vibrating screen for separating. After being separated, the crushed gypsum parts that can meet standard will be taken away as final products, while the other gypsum parts will be returned to impact crusher, thus forming a closed circuit.