Lindemann Germany GmbH

- Home

- Companies

- Lindemann Germany GmbH

- Products

- Lindemann - Model EtaPress - Scrap ...

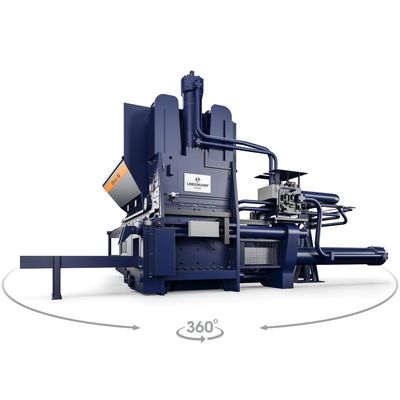

Lindemann - Model EtaPress -Scrap Metal Baler

LINDEMANN EtaPress balers set new standards in terms of operating safety, flexibility, and operating costs. They have a unique technological concept and easy-to-use, intelligent HMI. The EtaPress stands out on account of the same properties that have distinguished the brand for more than 100 years: quality, durability, and resilience.

Most popular related searches

metal baler

scrap metal baler

scrap metal

baler

load monitoring

proximity switch

scrap cable

car recycling

high density baler

metal baling press

The EtaPress has achieved a processing speed that is unsurpassed on the market at maximum availability – also in 24/7 use. At the same time, it stands for enormously high process reliability and resilience – premium quality that seeks its equal on the market in vain. It effortlessly processes a wide range of scrap: from car body parts of various qualities, sheet metal and profile scrap to mixed scrap, cables, wires, cans, etc.

-

Bale dimensions: 250 x 250 mm

to 600 x 600 mm -

Feed box volumes of 0.9 to 19 m³

-

Throughput/hour up to 59 t

-

No-load cycle times as fast as 25 seconds

-

Specific pressure 2,063 to 2,749 N/cm2

-

Maintenance friendly due to intelligent monitoring and easy accessibility

PRESS

TO WIN

TO WIN

All features of the LINDEMANN product line for maximum durability, performance, efficiency and maintainability

Triple action for best results

The LINDEMANN EtaPress has three-sided compaction with a hydraulic operating pressure of up to 350 bar. The optimized construction of the compression chamber made of smooth, thick plates for the EtaPress 22 to 44, and the design of the compression units with their adjustable mechanical stops, provide greater stability, durability, and operating safety under adverse operating conditions.

Increased uptime

The contact-free positioning system of the LINDEMANN EtaPress not only provides optimized cylinder control, but also bypasses the frequent interruptions caused by dirt or falling scrap disrupting limit or proximity switches.

Impressive peak performance

Load monitoring and optional energy-saving settings result in favorable energy consumption and low operating costs. The short cycle times of the EtaPress produce higher output relative to the installed power, thanks to the clever control system with oil transfer and hydraulic separation of the pump flows to move several cylinders at the same time.

Improved efficiency

LINDEMANN EtaPress offers high efficiency and, above all, high bale density. The baler processes an extensive range of scrap, ranging from car body stamping scrap, high-strength plates, thin sheet wastes, trimmings or cuttings through to cables, wires, long turnings or even mixed scrap, so that these materials can be recycled efficiently.