- Home

- Companies

- Linka Energy A/S

- Products

- Linka - Model Type 70 - Straw Shredder ...

Linka - Model Type 70 -Straw Shredder System

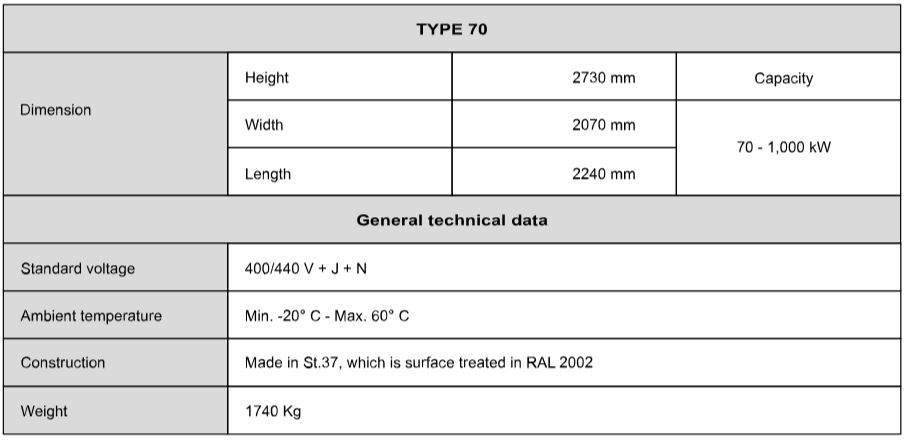

Efficient and well-proven shredder system for boilers from 70 kW to 1,000 kW. Linka Energy’s shredder system (SINGLE) is a well-proven straw shredder, designed, developed, and produced in the mid-1970s based on the experience Linka has gained through many years of working with biomass.

Since then, in 2009, the technology has been refined and developed into the shredder system we have today, which we proudly call the world’s best straw shredder.

The power consumption of the straw shredder is the lowest on the market, making it incredibly attractive for energy-conscious district heating plants, industry, and the biogas sector (for straw processing).

The LINKA shredder system can handle various types of bales, such as waste, seed grass, rapeseed, dry crops, dried manure, and similar materials.

The shredder system easily handles fuel with up to 25% moisture and processes both large and small fuel types without any issues. The system can be used for both pneumatic and auger transport, depending on the desired transport method and the distance between the shredder and the boiler system.

The shredder system can be applied in agriculture, industry, institutions, and heating plants.

The Linka® shredder uses a drum system that operates at low speed, which minimizes both the risk of spark formation caused by foreign objects in the fuel and wear on the system.

The fuel is pulled upwards, where it is shredded into smaller pieces, then it falls into the cross auger.

The cross auger then transports the shredded fuel to a suction pipe or auger, which feeds it into the stoker and then further into the boiler.

The forward movement of the conveyor belt is increased, and the pressure on the shredder drums is adjusted based on amp readings from the drum, until the desired oxygen level percentage is achieved. Similarly, the speed is reduced if the oxygen level is too low.

The shredder system can be equipped with conveyor belts of a desired length.