- Home

- Companies

- Kovalus Separation Solutions, Inc.

- Products

- Li-PRO - Lithium Extraction & Refining

Li-PRO - Lithium Extraction & Refining

Transformative Solutions for Battery Material Production. Proven, Innovative, and Unique Solutions: Koch Separation Solutions (KSS) is transforming the landscape of separations by leveraging synergistic technology such as membrane filtration, ion exchange, evaporators, and dryers. Our solutions are tailored to improve product quality, increase process efficiency, and drive down costs in dairy, food, beverage, life science, and industrial markets around the world.

Lithium Extraction

The shift towards efficient and sustainable lithium processing is driven by the growing global demand for lithium-ion batteries, primarily for electric vehicles. This invaluable resource, found in solid mineral and brine deposits around the world, has become a critical target for extraction and purification with demand rapidly exceeding supply. Efforts to optimize the battery recycling process are also underway to increase sustainability initiatives in the market, requiring innovative processing techniques.

To optimize operational effectiveness and meet demands for the highest quality lithium battery materials, KSS employs the Li-PRO™ Process, a series of specialized separation processes for lithium extraction and refinement. Advanced sorption technologies used to achieve direct lithium extraction (DLE) from brines. Membrane filtration and ion exchange are utilized in pretreatment and downstream refining, concentration, and conversion, supporting the production of high-purity lithium battery materials. In addition, for operations leaching lithium from solid mineral sources, our acid purification technology supports the recovery of leaching acids. Our integrated technologies and collaborative approach position KSS to be a preferred partner for customers seeking innovative and sustainable lithium production solution.

- Increased lithium recovery

- Higher purity product

- Improved process performance

- Reduced processing time

- Optimized operating and capital costs

- Simplified process flowsheet and smaller equipment footprint

- Fewer chemical and process water requirements

As a part of Koch Industries, KSS leverages a global reach and extensive resources to provide cutting-edge solutions for a variety of industries. Koch Industries has over 130,000 employees worldwide and reinvests 90% of its earnings to drive transformation and innovation.

Through Koch Industries, KSS is positioned to be a preferred partner and complete solutions provider to lithium producers. KSS’ parent company, Koch Engineered solutions (KES), provides a variety of internal resources to support project success, including engineering, procurement, and construction (EPC) services through Optimized Process Designs, LLC (OPD). Partnering with our sister company, OPD, as the EPC on lithium extraction opportunities allows KSS to be more than just a technology provider, as we package plant design and full-scale project execution into one comprehensive offering.

Koch Industries is also a major investor in the lithium market space, recognizing the need for alternative energy sources and the importance of sustainable technologies and engineering. Through Koch Minerals & Trading, LLC (KMT), Koch Industries invests heavily in lithium producers and participates in the trading of lithium battery material, providing these valuable resources to various end users around the world to drive innovation.

By partnering with KSS, lithium processors leverage synergistic technologies, provided in integrated system packages from a single source, to achieve optimal performance and efficiency. We work collaboratively with our customers, combining decades of separation expertise with their unique process knowledge to deliver start-to-finish solutions resulting in maximum value creation. Through early-stage lab testing and field piloting and demonstration, we help customers characterize their unique lithium brines and subsequently tailor DLE process solutions to ensure maximized productivity and efficiency.

Early-Stage Development

- Understand challenge & identify desired outcomes

- Evaluation of separation properties & bench testing

- Access to Process and R&D experts

Field Testing

- Pilot testing

- Process optimization

- Full scale costing and design recommendation

Full-Scale Execution

- Project management & execution of capital projects

- Construction and installation

- Commissioning and operator training

Long-Term Support

- Complete after-sales services

- System troubleshooting

- Performance optimization through remote digital monitoring program

Value Creation Through the Li-PRO Process

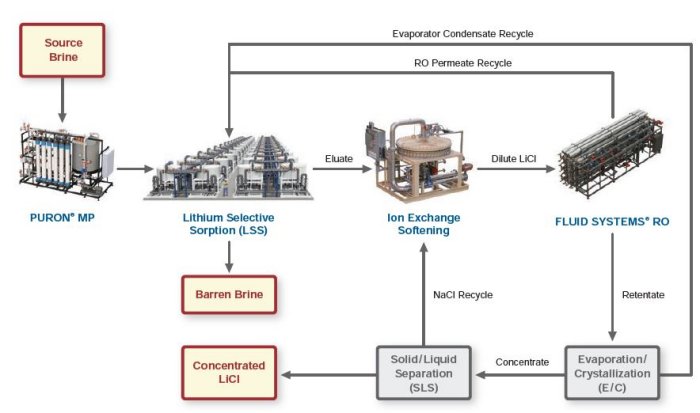

The Li-PRO™ process includes the pretreatment of source brine, lithium selective sorption (LSS), ion exchange softening, concentration using reverse osmosis (RO), evaporation and crystallization, and a solid/ liquid separation step to produce a purified, concentrated lithium chloride product suitable for conversion to lithium carbonate or lithium hydroxide for use in battery production.

Through various points of water recycle and a salt recycle stream, the Li-PRO process optimizes water and process chemical usage. Water from the source brine is collected as permeate from the RO and as condensate from the evaporator and recycled back to the LSS process step, minimizing external water usage and associated costs. Salt, collected as sodium chloride, is separated in a final solid/ liquid separation and recycled back to the LSS process step to aid in the chemical regeneration of the ion exchange softener. This effectively reduces salt or other chemical reagent purchases required for ion exchange regeneration. This process can be adjusted to accommodate operations where a salt recycle is not required or preferred.

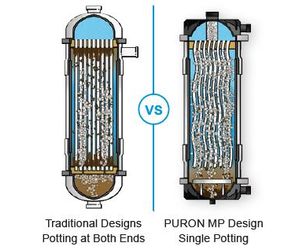

Our ultrafiltration (UF) membrane technology offers an excellent solution for pretreatment of brine. Featuring our PURON® polyester reinforced PVDF hollow fiber membrane, the PURON MP system treats a variety of water and wastewater. KSS is the sole producer of the innovative single-potting hollow fiber cartridge design, which works to reduce buildup and “fiber sludge”. The membrane is constructed with superior membrane chemistry and tight pore structure to deliver stable performance without the need for extensive chemical cleans. The PURON MP system offers an optimized design and operation to lower operating and capital costs. These skid-mounted systems produce high-quality effluent and demonstrate excellent solids tolerance.

The Li-PRO process approach to DLE uses highly selective sorption media beds to typically recover over 95% of lithium found in source brines, leveraging decades of ion exchange and sorption technology experience.

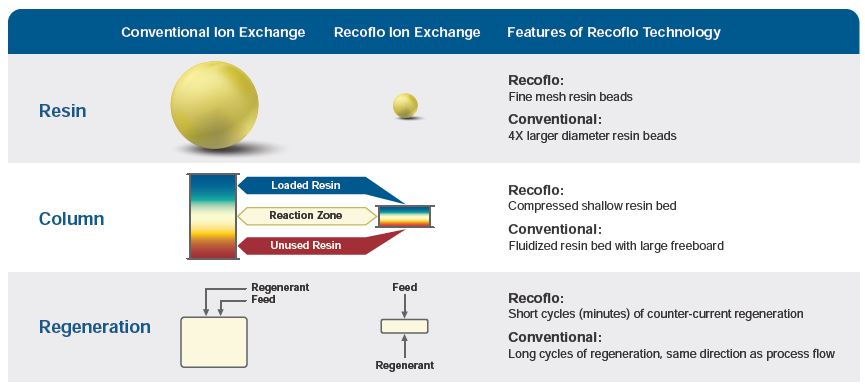

Raw lithium chloride brine extracted via the DLE process is further polished for divalent and other ionic contaminant removal by our Eco-Tec ion exchange technology. Based on our proprietary Recoflo fine-mesh ion exchange resin, our systems operate at high efficiency using less resin in a significantly more compact column design. These systems also offer capabilities such as leaching acid recovery and purification, salt separation, and further softening to promote a higher-purity final lithium battery material.

Our lithium extraction process is fundamentally supported by our proprietary Eco-Tec Recoflo ion exchange technology. Compared to conventional ion exchange resin, the Recoflo resin bead is a quarter of the size leading to higher packing density and surface area. By design, the required reaction zone is significantly decreased, and the system exists in a smaller footprint while maintaining high operational efficiency and reducing waste.

Our solution involves RO membrane systems to provide high recovery and high concentration capabilities for lithium extraction. Dilute lithium chloride is concentrated using RO technology prior to evaporation and crystallization. High-quality water recovered in this step may be recycled back into the process, improving sustainability, and minimizing water usage. Our spiral RO membranes are built with durability and reliability in mind to facilitate a simple and effective operation.

Fluid Systems RO System

The FLUID SYSTEMS RO system offers proven performance in the most demanding industrial applications. Operating within a compact footprint, this system offers a high recovery of up to 95% to produce high-quality effluent suitable for discharge or reuse. The system is reliable and simply operated and maintained.

KSS offers laboratory feasibility testing for any of our Li-PRO™ lithium processing capabilities. For even more representative testing and demonstration, pilot units are available for on-site testing, either for temporary evaluation or for purchase as part of a long-term overall process pilot plant. All laboratory and pilot engagements are supported by a team of experienced KSS engineers and technicians.

For lithium producers, the KSS team offers both standard and customized piloting options to accommodate a variety of capacities across the pretreatment, DLE, softening, and RO concentration process steps.

Standard piloting offering:

- Up to 1 gal/min of raw brine feed

- Up to 5 gal/min of raw brine feed

- Custom pilot plants can be provided at any capacity