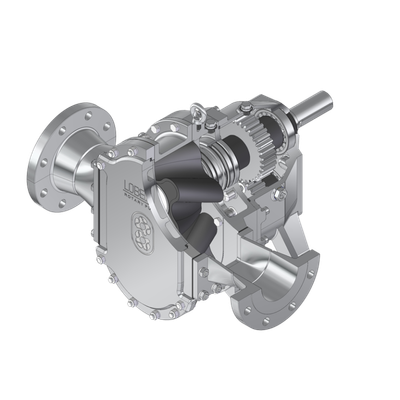

LobePro - Model API-Series - API 676 Compliant -Positive Displacement Pumps

LobePro manufactures Rotary Lobe Positive Displacement Pumps having an output range from 8 gpm to 2500 gpm with up to 175 PSI total pressure. LobePro API pumps meets the API 676 requirements with exceptions. We have developed our own patented LARS seal design, which can be adapted in include a Plan 32 flush. Our standard API pump pressure casing is Duplex stainless steel.

Our engineering team can perform all standard API tests including hydrostatic, performance and mechanical run testing in our test area. We will do a quality job of compiling all submittals to meet our customer’s requirements. The pumps are warranted for workmanship for 2 years. Should a pump you purchase from us require repair, we promise to ship the repair parts within 2 working days of order receipt or the parts are free.

In addition to providing the pump, LobePro can also provide the motor, gear reducer, and skid to your specification. We can also provide custom fabrications to suit individual applications.

Typical applications for our API pumps include fuel transfers; oil with abrasives; waste oil; crude oil; Vapor-liquid separator pump (aka flash drum pump, knock-out drum pump, compressor suction/ inlet drum pump); Induced Gas Flotation (IGF) froth pump; skim oil pump; desand slop pump; Produced Water Filtration Pump and highly viscous or abrasive chemicals. However there are many other applications because of the Properties of Rotary Lobe Pumps. Our engineers would welcome the opportunity to discuss your application and give you a quote.

The information below is from Hydraulic Institute self-study course entitled: Positive Displacement Pumps: Fundamentals, Design and Applications.

Listed below are 13 reasons why the Hydraulic Institute suggests using positive displacement (PD) pumps.

High Viscosity

Selected rotary technologies and air operated piston pumps easily handle highly viscous fluids. Due to high friction losses in centrifugal pumps, their flow rate and efficiency start to drop above 500 SSU. Flow and efficiency in a rotary pump, however, typically increase with viscosity. Positive displacement pumps can handle fluids with viscosities of several million SSU.

Low and Variable Viscosity

Positive displacement pumps, such as vane or air operated double diaphragm (AODD), are often applied on very thin fluids. Other liquids, such as oil, have viscosities that vary with temperature. With variable viscosity liquids, a moderately small change in viscosity may have a large effect on centrifugal efficiency but little effect on positive displacement pump efficiency.

Low Shear Pumping Required

In many fluid applications, liquid shear is not a problem; however, it is critical in some applications. Positive displacement pumps excel in the handling of shear sensitive fluids.

Solids Handling Capability

Progressing cavity pumps handling high solids content sludge in a waste treatment plant and reciprocating pumps are applied on coal slurry pipeline with solids contents as high as 40 percent by weight. This is sometimes a surprising positive displacement pump characteristic, but widely varied applications serve as examples.

Multi-Phase Flow

A constant source of liquid is a centrifugal pump requirement, but unfortunately all processes do not provide such constant sources. If there is insufficient liquid, a gas bubble forms in the suction and causes loss of prime (the pump stops pumping). Positive displacement pumps, on the other hand, are capable of handling a high percentage of air or gas entrainment.

High Pressure

Beyond the range of centrifugal pumps are many chemical, sandblasting and high-pressure water-cutting applications where positive displacement pump technology dominates.

Low Flow

Flow below 100-gpm and above 200-psi provides excellent application opportunities for postive displacement pump technology.

Efficiency

For viscous fluids where both positive displacement and centrifugal pumps can operate, Positive displacement pumps can often be 10 to 40 points more efficient than centrifugal pumps.

Combination of High Pressure/Low Flow-Efficiency Demand

Any of the previous three characteristics individually are a reason to use positive displacement pumps; however, in applications where all of these conditions occur simultaneously, a positive displacement pump solution is ideal.

Sealless Pumping (No Shaft Seal)

Magnetic drives and canned motor pumps are available in positive displacement pump designs. The requirement is also met by designs where the pumping environment does not have a shaft penetration, such as peristaltic or diaphragm pumps.

Self-Priming and Inlet Conditions

The ability to self-prime is a useful feature for positive displacement pumps as it allows substantial flexibility in system layout and eliminates the need for suction priming systems. Positive displacement pumps are self-priming, have excellent suction lift capabilities (raising liquids on the suction side) and are capable of drawing down to near vacuum.

Constant Flow Against Variable System Pressure

At a constant speed, positive displacement pumps deliver practically constant flow. Flow is constant even if the system pressure varies, which is a desirable condition in certain systems.

Accurate Repeatable Measurement

Since a positive displacement pump is a constant flow device, certain designs that limit slip are ideal for metering fluids in or out of systems. This application, of course, requires accuracy and repeatability. It also may need flow variation, which is typically obtained mechanically or electronically by speed variation.