Hung Star Enterprise Corp.

- Home

- Companies

- Hung Star Enterprise Corp.

- Products

- Hung Star - Model HS-D1216p - Long Arm ...

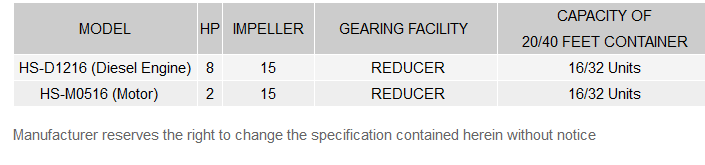

Hung Star - Model HS-D1216p -Long Arm Paddle Wheel Aerator

Driven by diesel engine especially suitable for area without electric support. With more impellers to improve pond water circulation and best oxygen. Less power consumption and less investment cost. Easy maintenance and energy saving. HS-D1216/HS- M1216 provide about 76.5kgs O2/Hr. Active horizontal water current about 70M. Active vertical water current about 1.6M to 2.5M. Flutter deep about 100-110mm.

Most popular related searches

paddlewheel aeration

paddlewheel aerator

boring machine

chamfering machine

pond water

lubricant system

water circulator

water activity

precision ball

water oxygenation

- IMPELLER:

- Trident model with special angle design make strong water flow and high oxygenation performance.

- Low maintenance cost and replaceable.

- Toughness with corrosion.

- FRAME:

- Sturdy stainless steel frame ensure duration and not deformation.

- FLOATER:

- One piece blow mold.

- Resist impact, Acid-alkalinity and UV.

- PLASTIC BEARING:

- Adjustment stand is accommodate to water level changed.

HIGH QUALITY DIESEL ENGINE:

- Newest current design,light weight and powerful output.

- Extra-big size of intake value with high efficiency 10% more than ordinary design.

- The specific compression ration is lifted higher than the compressive pressure, so it can have powerful output even under a heavy load.

- Adopts of precise fuel oil pump with the quickest acceleration. Also has designed with vortex pre-burning room at high combustion power to save oil.

- Lubricating system, cylinder with a cover,using of closed type auto oiling lubrication and multi-filter to have the best lubricating effect and to prevent parts from being worn.

- All components inside of the engine are treated under strict quality control, therefore, it can have excellent performance even for long period of running.

A fully closed engine design with improved muffler, noiseless and quiet for running.

REDUCER STRUCTURE

WORM SHAFT:

- The material of S45C is treated with high frequency waves to possess the hardness of HRC50°±3°.

- The tooth is ground with the professional shaft and grinder to decrease the friction coefficient and obtain accurate lead , pressure angle and tooth thickness.

- Meantime , the measure pin is used to inspect to control the accurate contact surface and the requirement of replace-ability.

WORM WHEEL:

- The tooth which is made of ALBC3,is formed with the professional tool machined with the precision hob and deburred with the chamfering machine.

- The precision steel balls are used to test the precision of the tooth.

BODY:

- The material is FC20. Before machining,red lead is sprayed to coat the internal and external surfaces of the body.

- Double boring machines as well as professional boring tools are applied to machine at a time to assure the same centerline and vertical angle of the bearings.