- Home

- Companies

- Watson-Marlow Fluid Technology Group

- Products

- Bredel - Long Life Hose Elements

Bredel - Long Life Hose Elements

Only Bredel precision machine every hose to guarantee tolerances and perfect hose compression. Pump life and efficiency depends on an original Bredel hose being fitted in our pumps. Bredel hoses: Choice of hose materials. Precision machined for perfect hose compression. Manufactured for optimum life and maximum pump uptime.

Key features of Bredel hose elements include:

- Choice of compounds for compatibility with virtually all fluids

- The hose is the pump - single component change and reduced inventory

- Multiple layers of nylon reinforcement for excellent suction and pressure performance

- 100% hose compression eliminates slippage

- Pump viscous and abrasive slurries and sludge with up to 80% solids in suspension

The hose element is critical to ensure pump performance, durability and efficiency. Bredel compositereinforced hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Excellent chemical resistance, especially to ketones, alcohols and concentrated acids.

- Max. fluid temperature: 194 F

- Min. fluid temperature: 14 F

The hose element is critical to ensure pump performance, durability and efficiency. Bredel APEX composite reinforced machined hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel APEX hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Excellent chemical resistance, especially to ketones, alcohols and concentrated acids.

- Max. fluid temperature: 194 F

- Min. fluid temperature: 14 F

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Outstanding abrasion resistance. Generally resistant to diluted acids and alcohols.

Natural rubber

- Max. fluid temperature: 176 F

- Min. fluid temperature: -4 F

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

- Outstanding abrasion resistance. Generally resistant to diluted acids and alcohols.

- Max. fluid temperature: 176 F

- Min. fluid temperature: -4 F

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers reinforced with up to four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – up to 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Resistant to oils, greases, alkalis and detergents.

- Max. fluid temperature: 176 F

- Min. fluid temperature: 14 F

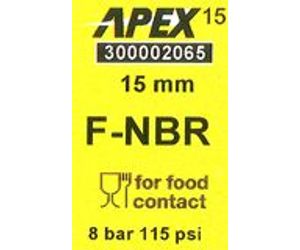

The hose element is critical to ensure pump performance, durability and efficiency. Bredel APEX composite reinforced machined hoses are constructed from high-quality compounded rubbers reinforced with several individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel APEX hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – up to 8 bar

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Meets FDA and 3A compliance. Resistant to oils, greases, alkalis and detergents.

- Max. fluid temperature: 176 F

- Min. fluid temperature: 14 F

- Maximum uptime, 80% longer hose life

- Meets FDA21CFR177.2600, EC 1935/2004 and BfR XX1

- 100% traceability and quality control throughout the supply chain

- Manufactured according to cGMP (EC 2023/2006)

- Delivered pre-cleaned and individually packaged

- Reduced maintenance

- Can be CIP/SIP cleaned

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compound rubbers reinforced with up to four individual layers of braided nylon, and finished by high-precision machining. White inner layer suitable for food contact. Outer layers are machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 9.5m (30ft) suction lift

- High pressure capability – up to 16 bar (231psi)

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity

Suitable for all food products including oils and greases. Meets FDA, EC, EHEDG and 3A standards.

- Max. fluid temperature: 176 F

- Min. fluid temperature: 14 F

Suitable for all food products including oils and greases. Meets FDA, EC, EHEDG and 3A standards. Available for APEX 10/15/20 pumps only.

- Max. fluid temperature: 80C

- Min. fluid temperature: -10C

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Outstanding resistance to strong, oxidising products and concentrated acids and bases.

- Max. fluid temperature: 176 F

- Min. fluid temperature: 14 F

The hose element is critical to ensure pump performance, durability and efficiency. Bredel APEX composite reinforced machined hoses are constructed from high-quality compounded rubbers reinforced with several individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel APEX hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 8 bar

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Outstanding resistance to strong, oxidising products and concentrated acids and bases.

- Max. fluid temperature: 176 F

- Min. fluid temperature: 14 F

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Perfect 100% compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Key features of Bredel hose elements include:

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Excellent suction performance – 30ft suction lift

- High pressure capability – 232 psi

- Repeatable volumetric accuracy to ± 1%

- Consistent capacity independent of varying suction and discharge conditions

- Exceptional performance when handling high viscosity product

Meets FDA standards, resistant to alcohols, acids and oxidising products.

- Max. fluid temperature: 140 F

- Min. fluid temperature: 32 F