- Home

- Companies

- Jiangsu River Heavy Industry Co., Ltd.

- Products

- River - Long Reach Boom

River - Long Reach Boom

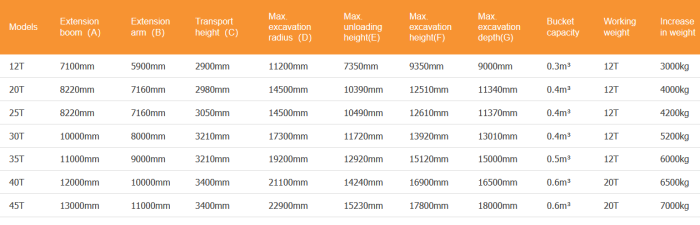

River heavy industry specializes in the design, production and custom-made long-reach arms for various brands of excavators. Our company is a leading manufacturer and supplier of long-reach arms in China, providing high-quality and durable extended arms to customers around the world. There are a variety of excavator extension arms available, ranging from 1.8 tons to 100 tons, with lengths from 8 meters to 30 meters. Depending on the customer’s requirements and application, excavator extension arms can also be customized.

Long reach front is an excellent solution for river and sea dredging on land or barge, pond excavation and maintenance, deep foundation excavation, drainage construction, distant digging, etc., especially beneficial for slope forming where standard boom failed to get the necessary job done effectively. There is no customized component/part used in our attachment; we design it with commonly available off-the-shelf components that customers can easily obtain from their local excavator spare parts market. Each long-reach package comes standard with the following items:

- 1x long boom

- 1x long stick/arm

- 1x bucket

- 1x arm cylinder

- 1x bucket cylinder

- 1x boom pin

- 2x arm pin

- 2x bucket pin

- 1 set of Linkage

- 2x pin for Linkage

- 1 set of hydraulic pressure hoses

- Full set of hydraulic piping/tubing

An extended arm is commonly used in construction activities such as river dredging, port work, subway work, foundation excavation, and others. With high efficiency and safety, it performs a wide range of operations. It is possible to improve productivity with a long reach boom produced by the river if the standard arm cannot be able to reach farther and longer digging distances.

Excellent Manufacturing and Processing Capabilities

As a manufacturer, we have a complete set of advanced processing and manufacturing equipment such as laser cutters, plasma cutters, welding robots, automatic coating lines, etc., capable of ensuring the fineness of products and a high level of production efficiency.

2. High-Quality Raw Materials

All steel materials are from China’s top steel manufacturers of reputable companies, and the extension arm is made of low-alloy high-strength plates with good tensile strength. Choosing the right materials for the boom and arm, as the most critical components on an excavator, directly affects the work efficiency.

It is also important to note that all hydraulic hoses are phosphated, which has excellent anticorrosion and antirust properties, and which can effectively protect the hydraulic system against contamination. Instead of the steel sleeve commonly used in the market, the copper sleeve is used on the connector.

3.Advanced Computer-aided Design Tools

With the use of CAD, 3D, and FEA structural design tools, our professional design team can provide accurate data analysis for secondary development and private customized products. In addition, they can upgrade products based on originality, thereby reducing production times. The risk of cracking and breaking of the long arms have also been taken care of.

4.Strict Production Process to Ensure Stable Quality

Every aspect of the production process is strictly controlled to ensure the highest quality products are delivered to our customers.