- Home

- Companies

- Falcon Autotech Pvt Ltd

- Products

- Falcon Autotech - Loop Cross Belt ...

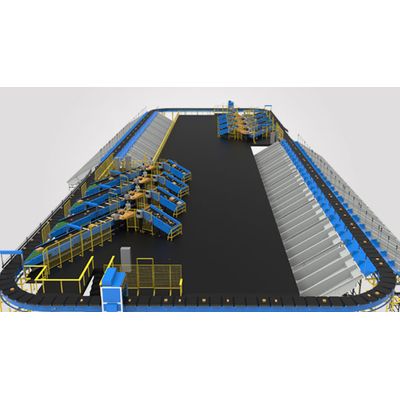

Falcon Autotech - Loop Cross Belt Sorter

Falcon Autotech’s Loop Cross Belt Sorter constitutes of modular sections offering high flexibility and scalability. It supports high number of end destinations and can achieve upto 2 times of the design throughput.

|

Property

|

Loop Single Belt Regular | Loop Dual Belt Regular |

| Min Product Size Sortable (mm) | 100x100x5 | 100x100x5 |

| Max product Size Sortable (mm) | 450x600x500 | 1000x600x500 |

| Throughput (Sorts/Hour) | 12000 - 24000 | 12000 - 24000 |

| Max Product Weight Sortable (kg) | 10kg | 10kg/Carrier |

-

Scalable and modular design.

-

Fastest Sortation System Available.

-

Gentle Product Sorting for Boxes and Pouches.

-

Narrow Sorting Chutes.

-

Highly redundant Design.

-

Completely Non Touch Carrier Actuation.

Induction

- AUTOMATED PARCEL FEEDERS

- SEMI-AUTOMATED FEEDER

- MANUAL FEEDING

Identification System

Falcon Autotech Cross Belt Sorter can be connected with a host of Product Identification Systems to relay the sorting decision based on Customizable business rules.

-

1D Laser Code Scanners (Multi Side Scanning Supported)

-

1D and 2D Image Scanners (Multi Side Scanning Supported)

-

Product Imagers

-

OCR readers

-

RFID readers

-

Special Symbol Readers

Discharge Chutes

- DIRECT TO BAG CHUTE

- DIRECT TO TOTE/CASE CHUTE

- SPOON CHUTE

- GRAVITY ROLLER CHUTES

- SPIRAL CHUTES

- DOUBLE LEVEL CHUTES

- L SHAPED CHUTES

- HEAD CHUTE

- J11 SPIRAL CHUTE

- ROLL CAGE CHUTE

- VDS CHUTE

Conveyors

Select the right conveyor depending on the product type and operations

- BELT CONVEYORS

- ROLLER CONVEYORS

LAUNCH PAD

Operators can drop the bulk parcels on the loading conveyor that slowly pushes the parcels on the orientation conveyor.

VOLUME DISTRIBUTION SYSTEMS

A system designed with single infeed point to distribute the bulk volume equally ensuring ample availability of parcels at inducts and increase in operator productivity.

PRE-SORTATION SYSTEM

A unique strategy used to achieve 2x of the designed sorter capacity by segregating the shipments for their respective induct zones mapped to specific end destinations.

DWS SYSTEM

Falcon Autotech uses most reliable dimensioning and weighing technologies from top global suppliers such as SICK, Mettler Toledo, OCS, etc. Capable of providing dimensioning accuracy of +-5mm and weighing accuracy of +-50 gm at high speed.

INFEED AND OUTFEED CONVEYORS

Wide variety of powered roller and belt conveyors for moving the shipments to and fro from the docks for complete automation experience.

TAKE AWAY CONVEYORS

Conveyors designed near the end chutes to carry the sorted shipment bags/crates/totes out from the sorting area and freeing the operators to continue their tasks.