Shincci - Low Temperature Sludge Dryer

Shincci™ Low Temperature Sludge dryer is able to achieve sludge volume reduction, stabilization, sterilization and reutilization. Its outlet dried sludge granule can be disposed with gasification, blended-burning, incineration; can be utilized as biofuel, construction material, cement material and landfilling material; It is applicable to transform any type of dewatered sludge (10% minimum dry content) into a dry, such as municipal, printing, dyeing, papermaking, electroplate, chemical, and leather, granulated product with a dry-solids content that can be adjusted within a range of 15% to 90%.

EFFICIENCY

- Sludge moisture content reduced from 83%to 30-10% (adjustable as required)

- Sludge volume is reduced by 67% and weight by 80%

- Drying process protects organics from losing, and retains the high heat value of dried material, adapting to the organics recycling use in later stage

ENVIRONMENT

- Very little odor emission during the process in a closed cabinet, thus no need for any expensive odor treatment devices

- Suitable for treatment plant in urban area

- Clear condensate is easy to deal with at flow head work, saving handling cost

SAFETY

- Low drying temperature 40-75? in a closed cabinet, no need for nitrogenization;no risk of dust or explosion

- Outlet Sludge<50?, no need secondary cooling and can be stored directly The sludge is placed in immobile state for drying. So there is no mechanical and frictional static with dryer contact surface

INNOVATION

- Non-conventional dryer, no need for high temperature heat source in open loop

- Using unique multi-effect dehumidification heat pump

- No heat waste during the drying process in a closed loop system

- World’s leading dehumidification technology, saves 50% compared to the conventional

ECONOMY

- 1 MT sludge drying from 80% moisture to 30%, operation cost only 180 kW.h at best performance.

- Or only 60 kW.h when using waste heat dryer

STERILIZATION

- Drying at 70? for 90-120 minutes, it can regards as pasteurization (low temperature heating sterilization) which may sterilize over 90% bacteria effectively

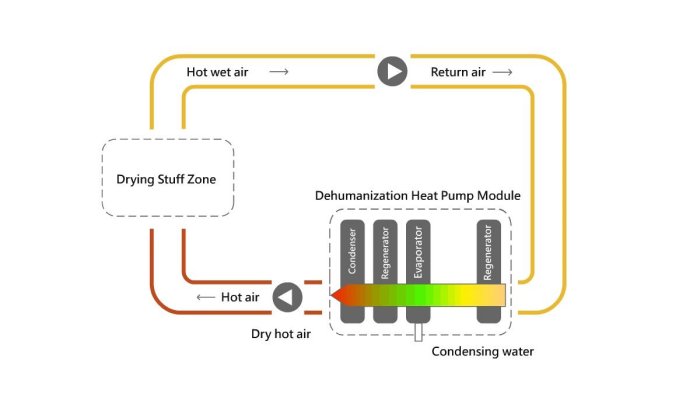

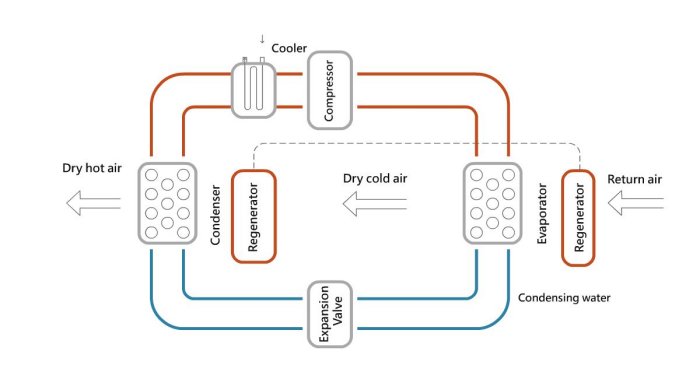

Mechanism:

Heat Pump Dehumidification= Dehumidification+ Heat Pump Energy Recovery

The Principle of Drying Material at Low Temperature

The hot dry air flows through wet materials and takes away moisture thus becomes hot wet air, which then passes through the cold end of heat pump and condenses the absorbed water (dehumidification). The cold dry air after dehumidification is then heated by the hot end of heat pump and becomes hot dry air (energy recovery). A new cycle starts.