Kelantechnics Environmental Products Co., Ltd.

Machine Tool Oil Mist Purification And Recycling Equipment

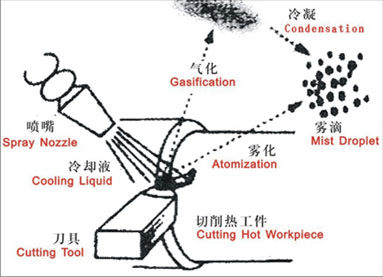

During the metal processing procedures, metal-cutting Oil mist is formed mainly due to atomization and evaporation: mechanical energy is transformed into droplet surface energy during the process of atomization. While colliding intensely with the fixed and rotary cells of the machine tool system, the oil-based metal cutting liquid is broken down into smaller droplets floating in the work environment. Evaporation happens when the heat transmission from the cutting area to the metal-cutting liquid is significantly higher than the saturation temperature of the latter. Boiling and Steaming would occur at the at solid-liquid contact surface. The steam then condense around small droplets or other particles in the air, thus the generation of oil mist.Most popular related searches

oil mist purification

oil mist

recycling system

oil recycling system

centrifugal fan

particulate pollution

air conditioning

fire hazard

oil recycling

hazardous cleaning

Influence of machine oil mist:

- Harmful to physical health: Oil (smoke) mist pollution may cause damage to your lungs, throat and skin

- Accident-prone Environment: oil mist may diffuse on the floor, making it more slippery and more prone to accidents.

- Prone to fire: Oil mist may accumulate, making it more of a fire hazard.

- Increased cleaning and maintenance costs: oil mist will pervade and adhere to the surface of such objects as the lightings, equipment, etc., then cleaning and maintenance is required.

- Influence the operation of equipment: the diffusive oil mist spread and accumulates so quickly and widely that malfunction of the machine tool system itself and electronic components of other equipment may be incurred.

- Environmentally destructive, waste of resources: If the oil mist is to be discharged directly into outdoor atmosphere, it would cause lots of damage to the environment; oil mist will reduce the effect of the air-conditioning and heating system, increasing energy consumption.

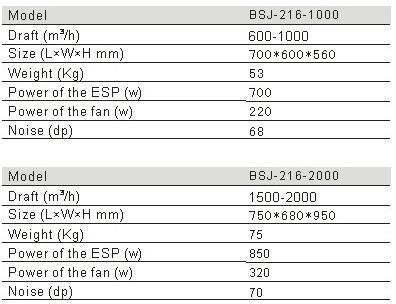

With the help of our BSJ series oil mist purification and recycling equipment for machine tools, whose capacities range from 600m3/h to 2000m3/h , 99% Oil mist produced during the drilling, turning, milling, broaching, grinding, polishing and other machining processes can be almost thoroughly collected for recycling purposes.

Characteristics:

- Specially designed to collect machine tool oil mist, aerosol spray, fume and particulate pollutants, suitable for direct indoor emission.

- Can be connected to the working stations or the pollution sources.

- Built-in centrifugal fan.

- Honeycomb Cylindrical Electric Field with patent.

- Composite draw-out structure of the purification cells, ensuring the ease of installation, maintenance and cleaning.

Product Models & Parameters