Erga DrumMag - Model IC -Magnetic Drum Separator

Automatic magnetic separation pulley for continuous removal of tramp metal of various sizes from bulk material.

- 2 in 1: magnetic iron separator + drive pulley

- Powerful permanent magnetic system

- Recovery of magnetic inclusions size up to 300 mm

- Sectoral magnetic system

- Operation with abrasive materials

- Automatic cleaning

- High energy efficiency

- Operation temperature range from -50°C to +50°C

- Easy installation and operation

Self-discharging ERGA DrumMag IC iron separation pulley magnet is installed in belt conveyor as a drive pulley, providing continuous high quality removal of coarse and medium sized strongly magnetic impurities from the conveyed flow.

2 in 1: magnetic iron separator + drive pulley

DrumMag IC is integrated in belt conveyor as a drive pulley, providing continuous high quality cleaning of raw material from strongly magnetic impurities.

Major assemblies of DrumMag IC separator are heavy-duty designed to handle additional loads from the conveyor belt.

Powerful permanent magnetic system

Automatic iron separator with magnetic intensity on the belt up to 0.3 T (up to 3 000 Gauss) ensures obtaining a saleable product in processing of slag dumps and ferrous scrap up to 300 mm; cleaning of raw materials from hardware, tramp metal or shredded tires from the cord.

DrumMag IC protects crusher and shredder from damage and premature wear.

Recovery of magnetic inclusions size up to 300 mm

Special magnetic system provides necessary long-range magnetic field for guaranteed recovery of magnetic inclusions with size up to 300 mm.

Sectoral magnetic system

Special multi-pole sectoral magnetic system provides “stirring” of magnetic inclusions in raw materials, which significantly improves quality of the products and separation efficiency.

Automatic cleaning

Cleaning of raw materials from magnetic impurities is automatic without personnel involvement.

Operation temperature range from -50°C to +50°C

Reliable magnetic system and simple design of the separator ensure its operability in a wide temperature range from -50° to +50°C.

DrumMag IC provides efficient operation in any weather conditions, indoors and outdoors.

High energy efficiency

Minimum power consumption required only for the conveyor drive and absolutely no consumption for magnetic field generation contribute to significant energy savings of the entire enterprise.

Guaranteed shelf life of magnetic system properties, subject to operating rules, is 10 years.

Operation with abrasive materials

The separator operating surface is made of durable abrasion-resistant chrome-nickel steel.

Easy installation and operation

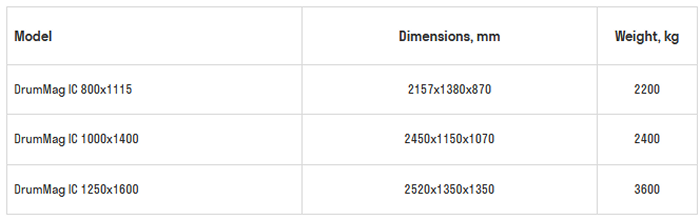

Installation and settings of the separator are easy: the machine has two bearing surfaces, compact overall dimensions and weight.

The product has a simple and robust design with little maintenance, all materials and components are tested by long-term operation at our customers’ facilities. Compliance with operation terms provided in IOM significantly extends its service life.

- lining

- bearings