- Home

- Companies

- Walle Industry

- Products

- Walle - Magnetic Separator

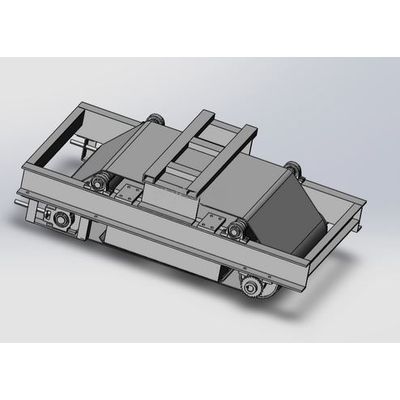

Walle - Magnetic Separator

Magnetic separator is one of the most widely used and versatile models in the industry. It is suitable for the separation of substances with magnetic differences. Magnetic separators are widely used in mining, wood industry, kiln industry, chemistry, food and other industries. For the mining industry, the magnetic separator is suitable for wet or dry magnetic separation of manganese ore, magnetite, pyrrhotite, roasted ore, ilmenite, hemalimonite and other materials with a particle size of less than 50mm. It is also used for iron removal of coal, non-metallic ore, building materials and other materials.

According to the type of magnet, it can be divided into: permanent magnet magnetic separator and electromagnetic iron remover [3]

According to the dry and wet of the ore, it can be divided into dry iron remover and wet iron remover

According to the magnetic system, it can be divided into: drum magnetic separator, roller magnetic separator, drum roller magnetic separator and flat plate magnetic separator.

According to the number of magnetic systems, it can be divided into single cylinder magnetic separator, double cylinder magnetic separator and combined multi cylinder magnetic separator.

According to the classification of ore feeding mode, it can be divided into: upper ore feeding magnetic separator and lower ore feeding magnetic separator.

According to the classification of magnetic field strength, it can be divided into weak magnetic separator, medium magnetic separator and strong magnetic separator.

According to the classification of magnetic system, it can be divided into: open magnetic circuit magnetic separator and closed magnetic circuit magnetic separator.

Wet permanent magnet drum magnetic separator is a kind of magnetic separator commonly used in iron ore concentrators. It is suitable for separating strong magnetic minerals. According to the different structural types of the tank, the magnetic separator is divided into three types: forward flow type, counter flow type and semi counter flow type. The selected particle sizes of three different tank types of magnetic separators are as follows: downstream tank ≤ 6mm, countercurrent tank ≤ 1.5mm and semi countercurrent tank ≤ 0.5mm.

The downstream magnetic separator has large processing capacity and is suitable for the rough selection and selection of coarse-grained strong magnetic materials. It can also work in series. When the feeding amount of downstream magnetic separator is large, the magnetic particles are easy to lose in the tailings. Therefore, the operation management should be strengthened to control the low pulp level.

Countercurrent magnetic separator is suitable for roughing and scavenging of fine strong magnetic minerals. The recovery rate is high, but the concentrate grade is low. Because coarse-grained materials are easy to deposit and block the separation space, the countercurrent magnetic separator is not suitable for handling coarse-grained materials.

Semi countercurrent magnetic separator can obtain high-quality iron concentrate and good recovery, so semi countercurrent magnetic separator has been widely used in production practice. It is suitable for the roughing and cleaning of ore particles below 0.5mm. It can also be connected in series and parallel to realize multiple sweeping and cleaning.