- Home

- Companies

- Maren Engineering Corporation

- Products

- Maren - Top Feed Shredder

Maren - Top Feed Shredder

Designed and engineered for the destruction of: Magazines, Signatures, Paperbacks, Tab Cards, Computer Printouts, Coupons, Blank Notes, And a variety of other materials.

Automatic High Volume Shredding Destruction and Baling

- Low noise levels.

- Heavy duty, super tough construction.

- Staggered, replaceable steel blades.

- Versatile design for various feed options.

- Automatic water spray for dust control.

- Adaptable to various balers or air handling systems.

- Interlocked electric control

Maren top feed shredders can`t be beat for safe high volume shredding for baling, and material destruction! Maren design and engineering offers flexibility in equipment layout as well as tough, heavy duty construction. This combination translates to efficient use of space and long dependable operation. Shredding before baling promotes dense, compact bales for savings and economy in both space and handling of waste material. Insurance against reentry into the market of sensitive materials is provided.

Maren`s standard top feed shredders are capable of shredding up to 3,000 lbs. of material per hour. Larger models can do more! These shredders are adaptable to pneumatic conveying systems, and to all Maren open end automatic and closed end balers. As material is fed into the top feed shredder, it drops into the rotating blades. The whirling blades shred the material into small irregular shaped pieces, and then discharges them automatically into a pneumatic conveying system or directly into an automatic baler.

- Top Feed : Shredders can be furnished with open top and closed srdes for gravity feed from above.

- Conveyor Feed : A conveyor may be used to deliver materials into the shredder.

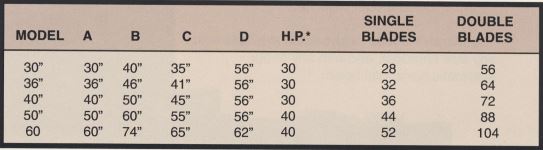

The single arbor design of each top feed shredder features staggered heat treated blades that are bolted to the arbor for easy replacement. Single and double blade configurations are available. Blades are reversible, thereby doubling the life of each blade.

Top feed piggyback configuration has the inherent advantage of otfering high volume shredding and baling without the need for substantial floor space. Both inline and 90 degree configurations are available. When providing a piggyback system, we will:

- Mount the shredder on a support stand, adjacent to the baler.

- Provide a transition chute between the shredder discharge opening and the baler feeder hopper.

- Interlock the electrical controls.

- Provide an automatic water spray system.

- Provide a dust collector

The Maren top feed piggyback is available with any size shredder, and with any of our automatic horizontal balers.