- Home

- Companies

- Suzhou Jono Environmental Technology ...

- Products

- JONO - Material Separation Ballistic ...

JONO - Material Separation Ballistic Screen

Ballistic screen is one of the main sorting machine. There are many models to meet all the screening requirements. The crankshaft is driven by a decelerating motor, which drives the shaft and eccentric shaft to rotate. The eccentric shaft connects the screening plate and rotates around the crankshaft in hula hoop mode. Material is bounced up on the screening plate. Because of the difference of friction (climbing force) between the screening plate and the material, the 2D material and the 3D material are separated.

Adopting the imported German crankshaft mechanism transmission, ballistic screen can sort the materials into three categories and bounce off the materials attached to the package to achieve an unparalleled sorting effect.

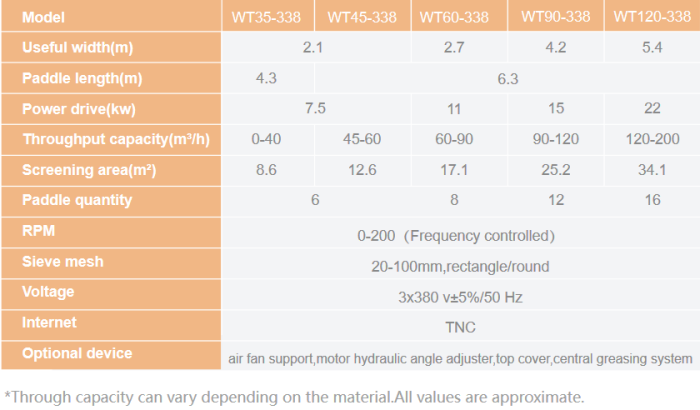

The crankshaft is driven by a decelerating motor, which drives the shaft and eccentric shaft to rotate. The eccentric shaft connects the screening plate and rotates around the crankshaft in hula hoop mode. Material is bounced up on the screening plate. Because of the difference of friction (climbing force) between the screening plate and the material, 2D and 3D material are separated. Processing capacity is up to 200 m³/h

- Mixed waste?Waste paper

- Waste derived fuel

- Biodegradable waste

- Domestic solid waste

- Industrial and commercial waste

By the active and passive crankshaft, the screen unit moves in a ovalcircle while the neighboring paddles moves asynchronously. When the material is dropped on the screen unit in the central area of the screen unit, the 3 dimensional material will bounce off the screen unit and the 2 dimensional material will climb over the screen unit and the small material screened out through the screen holes. By the way, the material is well separated into 3 types of material.

- Integral crankshaft, imported from Germany, with a lifespan of no less than 20,000 hours.

- Wind-assisted sorting to improve material screening effect.

- The screen plate is provided with an anti-wrap device to protect the crankshaft from being entangled.

- Swedish Hardox steel screen plates and side plates have high wear resistance and long service life.

- Use frequency converter to control speed and optimize performance.

- Centralized lubrication system make it easy to operate and maintain.

- Quick and convenient screen angle adjusting hydraulic device to optimize different material screening.

- Self-cleaning between screen plates to improve equipment efficiency.

- The quick-opening maintenance door at the rear is convenient and safe to operate.