- Home

- Companies

- Water Standard

- Products

- MDA - Membrane Deaeration - ...

MDA - Membrane Deaeration - Deoxygenation

Oxygen removal from injection water protects downstream facilities and reservoir integrity by preventing corrosion and bacterial growth.

Compared to conventional deaeration technologies, Water Standard’s compact membrane deaeration design offers:

- Significant footprint & weight savings

- Superior oxygen removal performance

- Reliable operation & low maintenance

- Reduced chemical consumption

- Competitive capital cost

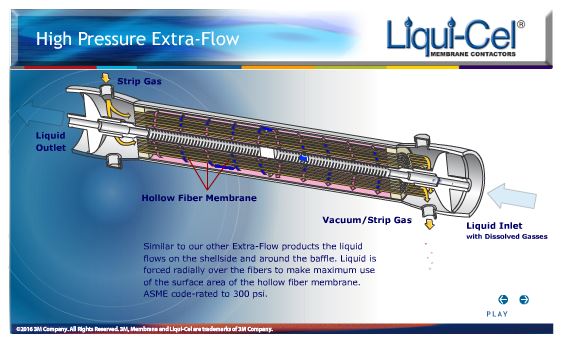

As a qualified Original Equipment Manufacturer (OEM) for 3M Liqui-Cel membrane contactors, Water Standard delivers turn-key membrane deaeration solutions and operations support to the oil and gas industry.

3M’s Liqui-Cel technology is commercially proven in industrial operations. It uses hollow fiber membranes to remove gases from liquids. The liquid is passed over the outside (shell) of the hydrophobic membrane, while the gas is stripped from the liquid using sweep gas on the inside of the fiber (lumen).

Water Standard’s designs allow for uninterrupted operation during cleanings and oxygen removal to

There are three membrane deaeration product models; however, the modular design provides the flexibility to treat flows up to several hundred thousand bpd. Complete instrumentation and a full functional test is provided prior to arrival on site.

The standard scope of supply includes:

- Membrane skid package with ASME coded pressure vessels

- Vacuum pump skid package rated for marine use

- Nitrogen generator package

- Materials suitable for marine environment

- All necessary equipment redundancy

- Piping, valves, instrumentation, and controls in accordance with the facility specifications and area classification

- CIP skid package with tank, pump, and filter

Standard options include:

Water Standard’s latest MDA design, the MDA Torrnado optimizes the equipment package even further by offering additional operational and economic benefits.

The MDA Torrnado design eliminates the need for vacuum pumps from the process. This creates a compact design with no rotating parts.

Energy for vacuum is provided via a pressurized motive fluid supply which can be a gas or liquid. In many cases, the motive fluid can be a process waste stream from elsewhere in the facility. These process waste streams could include excess facility seawater supply, desalination reject water, cooling water return, power generator effluent, and excess facility compressed air or nitrogen.