- Home

- Companies

- Stable Micro Systems Ltd

- Products

- Stable Micro Systems - Model Ceramscan ...

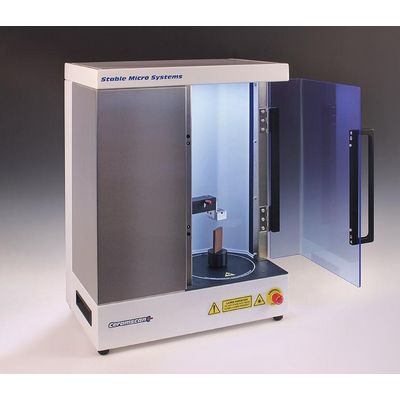

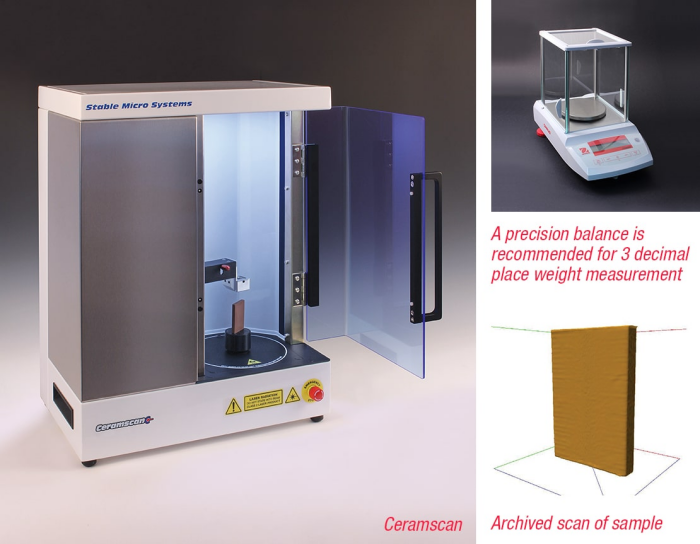

Stable Micro Systems - Model Ceramscan -Measure Ceramic Density

The Ceramscan is a benchtop laser-based scanner that measures the volume, density and dimensional profiles of Ceramic test pieces.

Measure more than volume

This non-contact measurement system offers considerable advantages over contact and displacement techniques which purely measure volume.

The rapid 3-dimensional digitisation of products enables the automatic calculation of several detailed dimension related parameters including volume, density and dimensions, the results of which may be mathematically manipulated for immediate use or future retrieval in a variety of data formats.

Fast and accurate

In as little as 12 seconds* manufacturers have precise data about their products in order to control and monitor their production.

*Based on a 10mm step size and 95% accuracy World class data analysis software

Our powerful, feature-rich software comes as standard. Your objective, quantifiable results can be archived and retrieved for future viewing, should you ever need to compare with historical data. Best of all, free software updates are included for the lifetime of your instrument. Find out more

Safer than outdated methods

Fluid displacement techniques are not suitable for porous materials. The Ceramscan is a non-contact laser-based measurement that is not affected by sample porosity.

Mercury displacement techniques represent a toxic risk to the environment and are therefore illegal in many countries.

The Ceramscan has been verified as accurate as mercury displacement method. Gas displacement techniques usually measure very small samples or otherwise attract a high instrument price.

The Ceramscan has the largest measurement envelope in its class. X-ray techniques are expensive and present a health and safety issue and therefore require fully trained operators. The Ceramscan uses an eye-safe laser and therefore is the safest procedure for density determination.

Fully rotatable test files

Appreciate the scan detail in every plane. The scanned data can be viewed in both 2D and 3D representations to allow comparisons with previous archived measurements. Within the 2D sectional view, additional manual measurements can be made on chosen intervals. 3D views of the product are rotatable in all planes providing flexibility of viewing for visual comparison and presentation.

Choice of Rotation Speed

For heavy or delicate samples, the centrifugal force created during the rotation can distort the sample or cause it to fragment or wobble and therefore a slower rotational speed is recommended. The fast speed provides the quickest scan times, but can affect the integrity of some products and produce less accurate results.

Easy verification

A measurement is only worth performing if it’s accurate. Check and verify yourCeramscaneasily by testing a Calibration and Verification Rod. The instrument will verify that the rod correlates with the measurement values as provided by the manufacturer so that product testing can continue with confiden

All of your data in one place

Provided by a built-in spreadsheet for data collection and statistical manipulation. There is no need to export data to another spreadsheet program, as the software for Ceramscan has its own integral spreadsheet, but Exporting to Excel is also an available option if preferred.

Export your data in .stl format

If you’ve designed a product in a CAD package and then 3D print it you might want to check that what has been printed is what you designed. Once the printed sample is scanned in the Ceramscan you can import the data as a .stl file which will allow you to import your file into popular CAD packages (maximum data size applies). You can then compare your CAD output with your CAD input. This closes the loop on the design and production of samples.

Presentation of your results

A report template is available into which your data can be dropped and automatically positioned with test data fields or modified using full Report Editing tools. Alternatively, images and data can be copied and pasted into other applications.

Operate in another Language using the Language Editor

Menu items and operator messages can be easily converted into your own language using a provided plug-in tool for language editing.

Barcode Scanner compatibility

Allowing quick product information entry and reducing user error. This device attaches via the USB port on a PC.

- World class data analysis software

- Complimentary software updates for the life of your instrument

- Complimentary technical support

- Extended warranty

- Bespoke test solution service

While our consumers are aware that our instruments are the best in the world, their decision to purchase one is not just based on the hardware. Ultimately, it all comes down to the service we provide to all of our customers. When considering the purchase of a laboratory instrument, our clients consistently cite our experience and desire to assist them with testing issues of all shapes and sizes as the number one reason why a Stable Micro Systems instrument is, and will always be, their first option.

Further information Buying advice

Read our guide Seven Tough Questions you should ask before buying a Volume Measurement Instrument

Instrument validation

We asked the Universitat Jaume I to compare our instrument to traditional ceramic density measurement methods. Read their findings

The Ceramscan is a benchtop laser-based scanner that measures the volume, density and dimensional profiles of ceramic test pieces.

The product is located on a sample platform tailored to the specific product. Parameters for each batch under test, which are entered into the software by the operator, include: sample ID name and date. The product is then weighed by either an external 3-decimal place balance which feeds the sample weight automatically into the software (so long as the balance can transmit displayed values as an ASCII string) or for samples of sufficient mass the instrument can weigh the sample automatically during a test. An eye-safe laser device is used to scan vertically to measure the contours of the product at selectable intervals whilst it rotates.

Each interval consists of 400 data points providing a detailed profile of the product. This assessment can be done rapidly, the results being obtained in a period ranging from a few seconds to a few minutes depending upon the chosen interval (0.05mm to 50mm) and the preferred precision. Temperature of the testing chamber can be measured automatically.

A full guide is available in Help File format to assist in setting up and performing tests, explaining the calculations and advising on optimum test settings to suit your product.

Sample Platform for Disposable Inserts

Disposable sample platforms provide the means to adhere samples to the platform and allow for quick removal and replacement between tests. They are located via a magnet and provided in batches of 50 which can be reusable, according to the chosen adhesive.

An instrument of this nature is a long-term investment. You’ll therefore want to make sure that its application is as universal as possible. Whilst your initial application requirements might be obvious you’ll want to make sure that your instrument can be applied to as wide a range of products as possible. Make sure you get the most value-added, feature rich instrument for your money to take your laboratory needs well into the future!

Using a non-contact laser-based method.

In ceramic engineering, the most common method for producing ceramic components is to form a green body comprising a mixture of the ceramic material and various organic or inorganic additives, and then to fire it in a kiln to produce a strong, vitrified object.

The measurement of bulk density of, for example, green ceramic tiles during production is a fundamental parameter for the quality of the product. The bulk density of a green ceramic body provides valuable information needed to control the quality of a ceramic piece (after firing) with respect to its final size and the porosity and cracks in the body and is proportional to the final mechanical resistance. It is therefore important that optimum measurement procedures are followed in determining density.

Bulk density is defined as the total mass of a body divided by the bulk volume. Bulk volume (or envelope volume) is defined as all space that is interior to the macroscopic “envelope” surface of the body. For a green body, the bulk volume includes the volume of solid particles, the volume of any temporary additives and liquid present, and the volume of empty pore space. This is what the Ceramscan can measure using its laser.

The porosity of freshly pressed ceramic bodies conditions green tile behaviour during the process (drying, glazing, and firing) and largely determines the properties of the final product. This makes it necessary to control tile porosity during shaping. Due to the difficulty of measuring ceramic tile porosity, bulk density is the physical magnitude that is actually measured to control the pressing stage.

Many ASTM methods for determining bulk density of refractory materials and glasses are described in books published by the ASTM. Most of these methods are based on volume displacement by Archimedes’ principle; that is, since both refractory materials and glasses are compatible with water, their bulk density can be easily determined by volume displacement in water. However, this test method is not suitable for green body ceramics, which will disintegrate easily in water. For green body ceramics, mercury pycnometry is recognised as the benchmark method for measuring the bulk volume of a body. Mercury is an excellent displacement liquid – its high wetting angle and large surface tension prevents it from penetrating into small pores in green bodies.

The most common method used to measure green tile bulk density has been by mercury displacement. The main advantages of this method are its ease of use and apparent high precision. Nevertheless, it has the drawbacks of being destructive, discontinuous, and manual. Furthermore, the high toxicity of mercury implies a grave health for workers performing industrial compaction controls and as such it is now illegal to use industrially in most parts of the world. This means that companies must look for alternatives to the use of mercury in tile bulk density measurement.

Why measure Volume, Density and Product Dimensions using a Ceramscan?

- Fluid displacement techniques are not suitable for porous materials. The Ceramscan is a non-contact laser-based measurement that is not affected by sample porosity.

- Mercury displacement techniques represent a toxic risk to the environment and are therefore illegal in many countries. The Ceramscan has been verified as accurate as mercury displacement methods.

- Gas displacement techniques usually measure very small samples or otherwise attract a high instrument price. The Ceramscan has the largest measurement envelope in its class.

- X-ray techniques are expensive and present a health and safety issue and therefore require fully trained operators. The Ceramscan uses an eye-safe laser and therefore is the safest procedure for density determination.

- If you’ve designed a product in a CAD package and then you 3D print it, one concern will be whether what has been printed is what you designed. In many cases you’ll need your printed object to be dimensionally accurate and iterations of printing your design are almost inevitable to adjust the printing settings to obtain a product that is dimensionally accurate. And you’ll need a means of quickly and accurately measuring these dimensions.

Learn what additional tests can be performed on ceramic and advanced material samples to better understand their physical properties.

Bricks, tiles, porcelain, pottery, glass, cement and concrete are all universally useful materials that have different purposes that we have discovered over the centuries. Whilst tiles have been placed on walls, floors and roofs (inside and out) we have been employing glass in windows and smartphone screens. More recently, advanced ceramics have been engineered for highly specific applications; silicon nitrides and tungsten carbides designed for making exceptionally hard, high-performance cutting tools, silicon dioxide and alumina used in making microchips and lithium-silicon oxide is used to make the heat-protective nose cones of space rockets.

These high-tech ceramic materials can be simple compounds or composite materials depending upon the desired end-product properties and their ordinary/extraordinary purposes. Whether they are visibly employed in the aerospace or construction industry for extraordinary applications or basic building materials or cutting tools, they can also be found hiding inside electrical and electronic material where they are chosen for different property reasons. Amongst the varying properties of scratch-resistance, heat-resistance, durability, hardness, strength, insulation or superconductivity in advanced industrial ceramics, there is also the need for ceramics in the world of medicine. The piezoelectric transducers that create ultrasonic waves used in pregnancy scans, hard dentures made from porcelain or bone implants that are cleverly designed to be porous so they promote natural bone growth – all incredible new uses for a well-known field of materials. And then, of course, there is the whole new world of 3D printing!

Whilst the development of new ceramic materials is helping to meet the growing demand in industrial and laboratory applications there is, and always will be, the need to measure and quantify the properties of both the raw materials and finished products in order to verify that their mechanical integrity is as required and expected. This is where a Texture Analyser/Materials Tester can be employed to compress, bend, stretch, extrude, cut, puncture or snap a product and provide an objective analysis of the material’s physical capabilities.

Here are just a few examples of typical ceramic product measurements and, where possible, a publication of where the instruments have been found in action.

Properties that can be measured:

Strength of Green Compacts

To produce structural parts from ceramics using a sintering process from powdered form, the powders must first be pressed into compacts at room temperature before baking in a furnace. The green compact resulting from this is not useful until it is sintered, but it must have sufficient strength to allow manipulation such as machining, and handling before sintering. This can be affected by many factors such as compacting pressure, powder properties, geometry and apparent powder density.

The strength of the compact can be measured using a compressive test, having accurately measured its dimensions, or using a Brinell hardness measurement in a flat sample surface. This book features the use of the Stable Micro Systems for these purposes.

Properties of Powders used in Green Compacts and 3D Printing

When a ceramic powder is used in powder manufacture of solid parts, the occurrence of caking or clumping can cause defects. Additionally, when the powder is being handled on an industrial level, a sample prone to caking can cause ratholes and expensive delays in the factory. The tendency of a powder to form clumps can be measured quantitatively using a number of measurements on a Texture Analyser. Static measurements include Unconfined Yield Stress, and Powder Vertical Shear Strength, whereas the Powder Flow Analyser , presents a widely-used dynamic measurement.

The bulk density of the powder can influence green compact strength. This can also be measured using the Powder Flow Analyser which uses a conditioning sequence to ensure powders have identical preparation before measurement, and a split vessel to cut the powder volume into a consistent volume. This measurement can be automatically combined with the measurement of powder caking, cohesion or speed flow dependency.

The manufacturer must know how a powder will respond to applied stress, including its relaxation behaviour. This can be measured using the Indexable Powder Compaction Rig, or for a more detailed analysis, the High Tolerance Powder Compaction Rig. For automated relaxation tests, the ALIS (Automated Linear Indexing System) can be used. These powder properties are equally applicable to powders used in 3D printed parts, an industry which is expanding rapidly in the ceramics field.

See a typical example in the powder metallurgy industry here.

Strength of Ceramic-Metal, Ceramic-Resin or Ceramic-Ceramic Bonds

The measurement of bond strength is of large interest to the dental industry, where strength of joins in the mouth, such as veneers and implants, are important to the application of these components. These bonds are generally tested in shear, although some publications have recommended a tensile or flexure test. All are possible using a Texture Analyser.

See a typical example in the dentistry industry here.

Strength of Joint Replacements

When a ceramic joint prosthesis is manufactured for use in the body, it is important to have full knowledge of its physical and chemical properties. These involve strength and fatigue testing of the whole component, or specific parts of the component under a set loading configuration. A range of strength and fatigue tests are possible using the TA.HDplus Texture Analyser, with a loading range of 0.5-750kgf.

See a typical example in the medical industry here.

Cyclical Fatigue of Ceramics

A property often associated with metal structures, cyclical fatigue can be a problem with ceramic materials too. When a high-performance ceramic is used as a structural component (such as at high temperatures in engines), knowledge of the effect of cyclic loading on fatigue failure is crucial, due to fluctuating stresses and strains. This is also an important effect on ceramics used in less extreme environments, such as ceramic crowns in the mouth or as stacked capacitors, as they undergo cyclic loading as a matter of course. Cyclical fatigue may be measured in compression, tension or flexure.

See a typical example in the dental industry here.

See a typical example in the electronics industry here.

General Compressive Testing

See a typical example in the dental industry here.

See a typical example in the bioceramics industry here.

See another typical example in the bioceramics industry here.

See a typical example in the medical industry (diametral compression) here.

See a typical example in the electronics industry here.

Patent – see how Ibidem Co. Ltd. used their Texture Analyser to measure breaking strength of the honeycomb structure filter fired body here.

General Tensile or Adhesive Peel Testing

See a typical example in the electronics industry here.

See another typical example in the electronics industry here.

General Flexure Testing

See a typical example in the dental industry here.

Puncture Testing

Patent – See how LG Chem Ltd used their Texture Analyser to measure perforation force of ceramic filter papers: puncture testing here.

A summay of the technical details of the instrument.

Technical Summary

Sample Dimensions

- Max diameter: 190mm

- Max height: 300mm

- Max sample weight: 3kg

Movement and Measurement

- Variable scanning resolution

- Minimum test time for 60mm product: 31 seconds (based on a 10mm step size, 1.5rps and 95% accuracy and constant ambient temperature)

- Rotational speed options: 0.5 / 1.0 / 1.5rps

- Data acquisition: 400 points per revolution

- Vertical step size options: 0.05mm - 50mm

Dimensions

- Instrument weight: 25kg

- Overall height: 639mm

- Overall width: 490mm

- Overall depth: 355mm

Mechanical

- Simple calibration

- Weighing via connected external balance recommended

- Door interlocking mechanism for additional safety - tests cannot be started unless door is closed

- Disposable Sample Platforms for permanent adhesive attachment

Electrical

- Operating temperature: 10° - 40°C (non-condensing)

- Ambient temperature measurement recorded automatically

- Universal mains input voltage: 100-240 V AC 50/60Hz

- Connectivity: USB

Optional Additions

- Calibration and Verification Rod

- External Precision Balance – option of communication with external precision balance (that can transmit displayed values as an ASCII string) via PC COM port

A measurement is only worth performing if it’s accurate. This is why you’ll want to have control of instrument calibration and the means of verifying that the instrument is measuring accurately by testing a Calibration and Verification Rod.

The instrument will verify that the rod correlates with the measurement values as provided by the manufacturer so that you can continue your product testing feeling confident that your instrument performance has been checked.

Typical PC Requirements

- 2.5 GHz modern Intel 32 bit or 64 bit Multicore CPU or AMD equivalent

- 4 GB memory

- 2 GB free hard disk space

- OpenGL or DirectX 9.0c compatible graphics card

- Supported operating systems: Windows 10 and 11

The latest software versions are available to download free of charge here.

The Ceramscan is complementary to Stable Micro Systems` wide range of texture analysis and physical property measurement solutions which are developed and manufactured in-house and supported by a qualified technical applications team and international distribution network.

We asked the Universitat Jaume I to compare our instrument to traditional ceramic density measurement methods.

In ceramic engineering, the most common method for producing ceramic components is to form a green body comprising a mixture of the ceramic material and various organic or inorganic additives, and then to fire it in a kiln to produce a strong, vitrified object. The bulk density of a green ceramic body provides valuable information needed to control the quality of a ceramic piece (after firing) with respect to its final size and the porosity and cracks in the body and is proportional to the final mechanical resistance. It is therefore important that the optimum and most accurate measurement procedures are used in determining density.

The most common method used to measure green tile bulk density has been by mercury displacement. The main advantages of this method are its ease of use and apparent high precision. Nevertheless, it has the drawbacks of being destructive, discontinuous, and manual. Furthermore, the high toxicity of mercury implies a grave health for workers performing industrial compaction controls and as such it is now illegal to use industrially in most parts of the world. This means that companies must look for alternatives to the use of mercury in tile bulk density measurement.

How the validity of the Ceramscan was measured and proven

As the existing density measurement is well known it is, of course, the method that we must successfully compare with in order to convince the industry of its suitability for method replacement. To do this, we engaged with the University of Jaume in 2018 to do a direct comparison between the two methods using the same samples. They prepared a detailed report of the findings of this research and an objective summary of the comparison between the two methods.

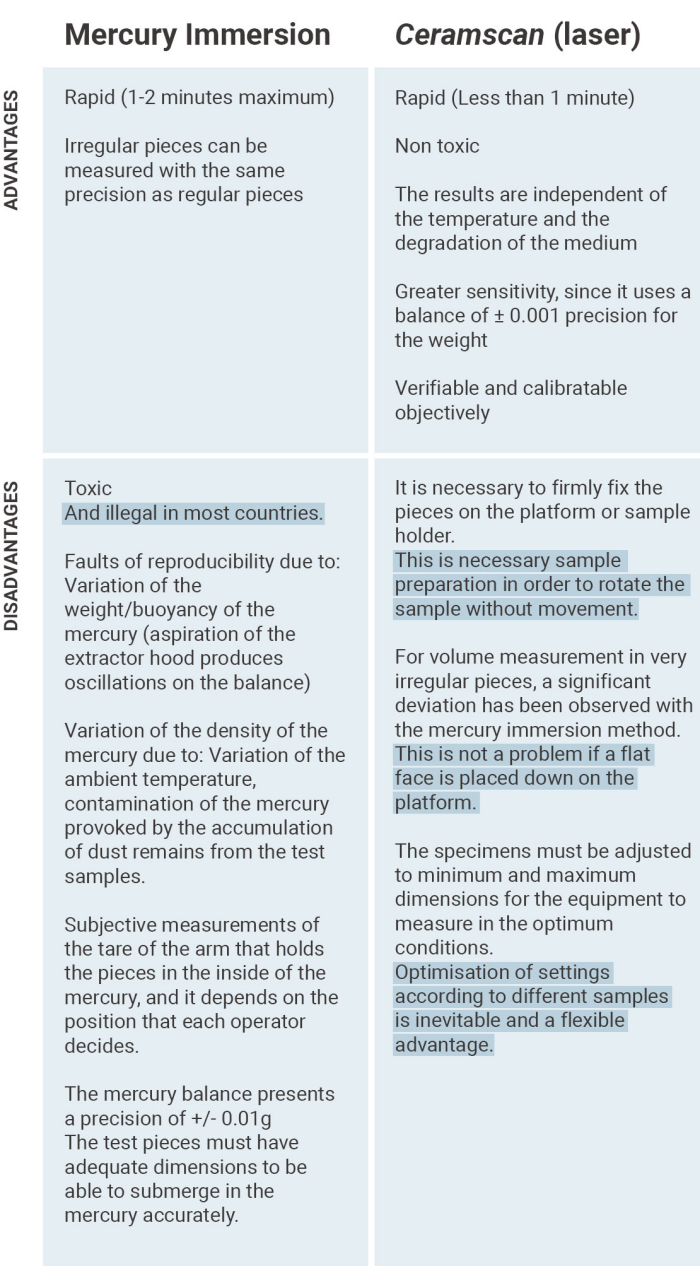

Their full report is available but the following bullet points and comparison table summarise their findings. Our own comments (in blue) have also been added to accompany their text.

Mercury immersion vs the Ceramscan

Comparison of the advantages and disadvantages of the two measurement methods. Stable Micro Systems response to the findings highlighted in blue.

Conclusions

As provided from Director del Grupo de Investigación de Química del Estado Sólido

- The determination of bulk density by the method of immersion in mercury poses a risk to health and hygiene at work, in addition to generating toxic waste for the environment.

- The reproducibility of the mercury immersion method depends on the environmental conditions such as possible air currents generated by the hood extractor, the environmental temperature that affects the mercury density, the dirt that accumulates in the mercury and also of the technician who makes the measurement.

- The Ceramscan equipment, based on laser technology, is a more hygienic and environmentally friendly alternative to conventional mercury immersion for the determination of solids bulk density, the result of which does not depend on the ambient temperature or of the alteration of the measurement medium.

- In general, when dealing with regular geometrical pieces, the Ceramscan equipment has allowed measuring with standard deviations lower than 0.005 g / cm3 in 48 seconds (0.5 mm vertical pitch and 1.5 rps rotation speed and subject to the sample holder with a Sika adhesive), the percentage of deviation with the mercury immersion method being less than 1%. However, when it comes to very irregular pieces, the deviation of both methods exceeds 2%, although they are also subject to said adhesive.

- The reproducibility of the Ceramscan equipment is adequate when the pieces are regular and are fastened with the Sika adhesive, using 0.5 mm vertical pitch and 1.5 rps rotation speed, which, depending on the size of the piece, can reduce the measurement process to times less than one minute.

- It is recommended that the specimens to be tested have adequate dimensions and a geometry as regular as possible so that the Ceramscan equipment measures with the maximum precision and speed.

Why we chose the Universitat Jaume I for validation

More than 90% of Spanish ceramic tile is produced in the Castellón Cluster, which is made up of 223 companies and is comprised of the geographical areas of Plana Alta, Plana Baixa and Alcala-ten concentrated in a 20-km radius. Central in this region is the University Institute of Ceramic Technology of the Universitat Jaume I. The Universitat Jaume I and the Spanish Society of Ceramics and Glass (SECV) together develop projects in the field of ceramic and glass materials. Jaume I University offers advice to organisations to implement innovation and technology solutions. With an open innovation model, the Universitat Jaume I collaborates closely with different organisations to promote instruments that carry out different parts of the process of knowledge and technology transfer in their field. It was therefore natural to choose this institute to perform an impartial research project within the area of their expertise of ceramics technology.