- Home

- Companies

- Stable Micro Systems Ltd

- Products

- Stable Micro Systems - Model Powder ...

Stable Micro Systems - Model Powder Flow Analyser -Measure Powder Flow

An accurate and reliable method of measuring the flow characteristics of powders.

Controlled Flow measurement

Test virtually any material capable of flow and displacement – not just free flowing powders. Impose extremely gentle through to aggressive flows, and measure the resulting force to characterise the sample under those controlled conditions. Users can define sample flow to suit the sample type and characteristic of interest, or to be complementary to the process conditions experienced by the sample.

Apply multiple actions

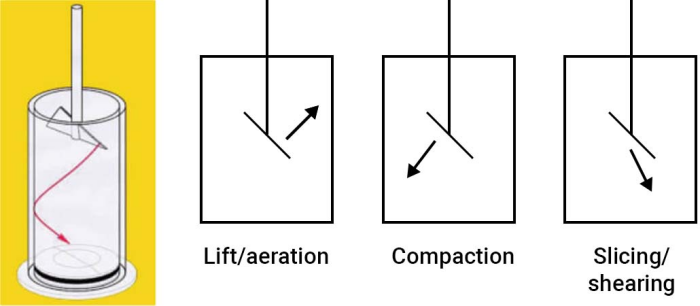

Compaction, slice, shear, lift/aeration are all achievable and test programmable in the manner most suited to the sample and your process need.

Measure multiple characteristics

Measure cohesion, caking, bridging, bulk density, compressibility, relaxation, stiffness, elastic recovery, and powder flow speed dependence.

The complete testing solution

Stable Micro Systems use the test frame and vertical drive system provided by a universal Texture Analyser, and add the rotational drive and software functionality to form the Powder Flow Analyser. Remove thePowder Flow Analyser for the ability to measure more powder characteristics such as: caking after consolidation, unconfined yield stress, vertical shear strength and compactability. Alternative powder flow products are not nearly as comprehensive.

Superior engineering for accurate results

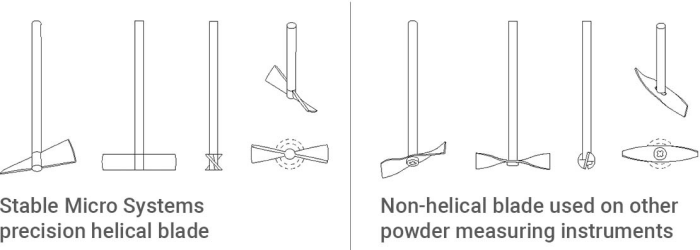

Our blade is a true helix and can be mathematically described, unlike the blades fitted to other powder measuring devices on the market.

Built to last

Coupled with easy-to-use Exponent Connect software, this versatile instrument is extraordinarily well-engineered for long-term reliability and accuracy.

Run from any device

All Stable Micro Systems Connect series Instruments are capable of operation by the standard equipment Touchscreen Interface as well as by a desktop or laptop PC. In addition, they may also be operated from a mobile phone or tablet using the Browser Interface. Learn more

Powder Flow Analyser Controlled Flow provides:

- User programmable tests that displace the sample by slicing, shearing, compressing, compacting, mixing, and aerating; in any combination, and in any sequence

- Exact repetition of the test sequence best suited to your need, time after time. Test Settings can be optimised to show the maximum differentiation between similar products, or to imitate the process or storage handling conditions, experienced by the product.

- Independence from variable sample loading by pre-conditioning at the start of the test

- Extremely gentle through to aggressive displacements

- Measurement and analysis of force, time, and distance; parameters that define the sample behaviour during the programmed Controlled Flow

- Objective, numeric, automated analysis, characterising of the flow behaviour of the sample during Controlled Flow

Repeatability and Reproducibility

Controlled Sample Flow enables the powder column sample to be pre-conditioned before the actual test cycle. This provides independence from operator sample loading techniques and results in repeatable sample flow programs that provide reproducible results.

Precision machined and surface finished rotors and blades for displacing the powder and borosilicate glass or stainless steel test vessels assist in reproducibility of results. Meanwhile, software allows data capture at up to 2000 points per second (pps) providing detail for analysis enhancement.

Sample size

From less than 20ml to over 200ml – where samples of bulk solids are extremely rare or very expensive, e.g. in the pharmaceutical industry, samples down to 20ml can be analysed.

Ease of use

Samples can be pre loaded into sample vessels and pre conditioned for humidity and temperature. Additionally, test vessel bases are easily removed to enable thorough, simple cleaning.

Flexibility and versatility

Customise sample test projects, create your own protocols to test in another way or analyse data to collect additional parameters.

Measure additional physical parameters of your powder or finished product (e.g. Unconfined Yield Stress, Granule Crush Strength, Cake Compression Strength) with optional accessories for the Texture Analyser. The testing possibilities are endless.

Avoid typical problems

Manufacturers can assess and avoid typical problems such as batch and source variation of ingredients, caking during storage or transportation and problems with discharging from hoppers or bins.

The instrument of choice for leading companies and universities across the globe

While our consumers are aware that our instrument is the best in the world, their decision to purchase one is not just based on the hardware. Ultimately, it all comes down to the service we provide to all of our customers. When considering the purchase of a laboratory instrument, our clients consistently cite our experience and desire to assist them with testing issues of all shapes and sizes as the number one reason why a Stable Micro Systems instrument is, and will always be, their first option.

Further information Case Studies

Explore our case studies to see how our customers have used their instruments to further their testing requirements and find solutions to testing problems.

Fully programmable, thePowder Flow Analyserhelps to open up a new world of testing.

A typical powder flow analysis test

A typical test starts with conditioning the powder column to remove operator loading differences.

During the test, axial force, time and distance are measured by a sensitive transducer and data is displayed and analysed in real time byExponentsoftware. Sample results can be ranked and compared to assess the impact of external conditions including humidity and moisture content, surface properties, electrostatic charge and particle or granule size, shape and distribution.

The Powder Flow Analyser is supplied with library tests, so operators can start testing quickly and conveniently after straightforward installation and calibration. Users can, however, fully program the instrument to carry out slicing, shearing, compressing, compacting and aerating cycles in any combination.

Controlled Flow Displacement

Depending upon the programmed rotation of the blade in terms of path angle, blade direction and tip speed the powder column can be displaced in a number of different ways to suit the process and properties to be measured.

Lifting/Aerating – this action allows the powder column to be conditioned, thereby giving independence from sample loading variations. It can also effectively measure particle cohesion and flow behaviour after compaction has been employed.

Compaction/Compressing – this method allows the measure of flow properties with changing compaction force and flow speed and provides an investigation of caking potential.

Slicing/Shearing through a powder column allows movement through the sample with minimum disturbance when required by moving at the same helical path angle as the blade profile. This may be desirable when required to move downwards through the column with minimum disturbance and therefore effect on the sample in order to measure a characteristic on the upward cycle of the test or when looking to `cut` through a column in order to measure the strength of a cake that has been formed after compaction/consolidation to a specified stress in order to imitate storage conditions.

Controlled Flow Measurement

The Powder Flow Analyser Controlled Flow Measurement technology offers you the ability to physically displace the powder in a controlled manner that can be optimised to measure the differences between samples, or can be adjusted to be complementary to your process conditions.

The force resulting from the displacement is accurately measured and used to characterise and rank the sample.

From an engineering perspective: The precision blade is a true helix and can be mathematically described, unlike the blades fitted to other powder measuring devices on the market. The helical blade naturally cuts through the column of powder being tested and negates the need for complex torque measuring systems. Repeatably manufactured by Selective Laser Sintering and polished to a specific surface smoothness, it allows Stable Micro Systems to achieve very reproducible, and highly discriminating results.

Commenting on the blade, Jim Walker, Founder and Director at Stable Micro Systems, says: "The design of the blade is the single most important factor in achieving repeatable powder flow measurements. The non-helical blade used on other instruments is bent from a flat sheet and presents a large flat central area to the powder being tested. It effectively compresses a column of powder beneath the blade during its travel path through the sample. As a consequence, any axial force readings being taken are corrupted and these instruments are forced to rely on torque measurements because of the inadequacies of blade design."

Keeping powders flowing correctly and consistently is critical in all stages of manufacturing and through to the end user.

It is estimated that over 50% of all materials used in all industries are, at some stage, in powder form.

An objective measure of powder and granule flow can:

- Allow customers to avoid the extensive costs and time involved in unloading powders that will not flow out of storage containers

- Help achieve the best product formulation with the properties to suit the requirements

- Improve the quality and consistency of the product

- Save costs by optimising storage, packing, handling and transportation

Stable Micro Systems` Powder Flow Analyser is an accurate and reliable method of measuring the flow characteristics of powders.

Manufacturers can assess and avoid typical problems such as batch and source variation of ingredients, caking during storage or transportation and problems with discharging from hoppers or bins. Find out more about typical powder flow issues

Learn more about the Powder Flow Analyser

Typical powder flow issues

Process Development

If yours is one of the millions of companies using powders in a manufacturing process, you don`t need us to remind you how vital it is to keep your production line running smoothly. The consequences of, for example, consolidation during storage or transport or the formation of a blockage in a hopper could be both very inconvenient and very costly.

Measurement of the flow properties will enable objective accept/reject decisions to be made, whilst the knowledge of a powder`s characteristics before and during its processing will enable the formulation and key process steps to be optimised when conveying, mixing, tabletting and storing the powders, resulting in a more cost effective controlled operation of the process.

Quality Control – Monitor Batch and Source Variation

When a new supplier is selected, or even when a new batch of product is delivered from the usual supplier the variation in flow properties can lead to large problems during storage and handling. The Powder Flow Analyser allows the quality control of the newly delivered items.

Tests can be carried out in a short time to generate a reading that tells an operator whether the powder will handle/perform in an acceptable manner. This philosophy allows users to test powders in small volumes before deciding to fill up a silo or start processing, thus leading to large savings in terms of time and money usually resulting from unloading jammed silos.

Formulation Development and Quality Improvement

R&D teams need to optimise the mixing of powders and addition of flow aids. This is necessary to achieve the optimum performing final product without risking flow problems or over-using expensive flow improvement additives which may cause end product deterioration and costly waste.

The Powder Flow Analyser allows product development teams to test out the flow properties of new product recipes and mixes before running the powder through the process or loading up a large container. You will be able to rank and relate powder measures to process and end product features.

Product Substitution

During the course of a product`s life cycle, cheaper alternative ingredients are likely to be discovered. Whilst on the surface these cheaper ingredients might appear to have the same specification, they may not behave "the same", as a product with the same name can have a wide variation of properties.

Confidence checks will need to be carried out to ascertain whether they convey and flow after storage in the same way, whether they are equally affected by, for example, moisture and temperature, and whether these cheaper ingredients would ultimately increase factory costs as a result of having to spend time unblocking processes and silos.

Product Handling

Measurement of powder flow enables assessment of the powder`s behaviour when in Conveyors, Chutes, Silos, Air lifts, etc. and when, for example filling packs, bottles and capsules to a minimum weight. During storage, conveying and in transportation such issues as segregation, attrition and agglomeration can occur.

Obtaining measures of cohesion, caking, powder speed flow dependence means that powders can be characterised by several numbers to create a "fingerprint" rather than inadequately with a single value. The fingerprint can then be investigated with reference to changing parameters such as humidity, compaction pressure, particle size and shape (to name but a few).

Authority Requirements: EMEA, FDA, Weights and Measures

Measurement of powder flow enables assessment of behaviour when, for example, filling packs, bottles and capsules to a minimum weight. Flow behaviour will undoubtedly affect, for example, tablet hardness and capsule fill weight, both of which are likely to be strictly controlled to tight specifications.

Understanding and improving the variation in fill weights due to tighter control of the flow properties of the powder allows reduction in waste and subsequently improves profit.

Slicing/Shearing through a powder column allows movement through the sample with minimum disturbance when required by moving at the same helical path angle as the blade profile. This may be desirable when required to move downwards through the column with minimum disturbance and therefore effect on the sample in order to measure a characteristic on the upward cycle of the test or when looking to `cut` through a column in order to measure the strength of a cake that has been formed after compaction/consolidation to a specified stress in order to imitate storage conditions.

Movement and Measurement/Performance

- Force Down: 5kg (50N) maximum

- Force Up: 5kg (50N) maximum

- Force Resolution: ± 0.5%

- Force Zero Hysteresis: < ± 0.2g

Rotor Tip Speed for 48mm blade

- Dependent on test angle

- At 0°: 0 to 754mm/sec (300rpm max rotational speed)

- At 90°: 40mm/sec*

Rotor Tip Speed for 23mm Blade

- Dependent on test angle

- At 0°: 0–350mm/sec

- At 90°: 40mm/sec*

Vertical travel

- 180mm minimum*

Data Acquisition Rate

- 2000 points per second

Dimensions

- Component parts contained within Texture Analyser dimensions*

Operating Conditions

- Dust and splash resistant

- Temperature: 0–40°C

Component Vessels

Precision bore, borosilicate glass tube

- 25mm diameter – 45ml volume

- 50mm diameter – 200ml volume

- 50mm diameter split vessel – 200ml volume

Blades

Selective Laser Sintered DMLS Stainless Steel 316 with surface finish polish to Ra 0.5 micron

- 23.0mm diameter x 10mm wide

- 48.0mm diameter x 10mm wide

Power Requirements

- Supply voltage range: 90 to 264VAC

- Input frequency range: 47Hz to 63Hz

The following accessories are available for attachment to the Powder Flow Analyser to extend your powder property measurement options:

Test Vessels

Vessels hold the required volume of powder/granule material to enable powder flow measurements to be performed.

Precision tube in borosilicate glass with removable acetal base attachment ring to enable easy cleaning.

Vertical alignment and radial tolerance better than ± 0.05mm. Special materials and sizes on request.

Vessels are supplied individually or in sets of 3 and are available in 2 sizes:

- Typical sample volume 100-200ml: 50mm internal diameter / 130mm total height

- Typical sample volume 20-35ml: 255mm internal diameter / 80mm total height

Rotors

Rotors provide controlled powder flow via patented precision blade action and enable measurement of caking, cohesion and powder flow speed dependence.

Shafts: 6mm diameter 316 Stainless Steel

Blades: 48mm diameter and 10mm height. Precision machined to optimise blade form. Over Anodised (Clear) Aluminium Alloy or 316 Stainless Steel as standard. Special materials and sizes on request.

A vast range of powders – a wide range of tests. All types of powder need to flow.

Applying Powder Flow Analysis to different industries

It is estimated that over 50% of manufactured products are powders at some stage during their production.

These powders will possess a wide range of properties such as consolidation caking, cohesion, and powder flow speed dependence, all of which will impact on their storage and bulk flow.

Many powders can potentially gain strength and cake during processing, storage and transport to the final consumer, causing the formation of lumps and aggregates, or they may be transformed into a caked bulk. This can be very undesirable, causing production delays and lost production, and represents a major product quality defect in the eyes of end-users of powder products. Raw ingredients can be assessed on a regular basis to keep watch on batch and source variation and finished products in powder form can undergo a full assessment to measure the properties (e.g. fully flowing, caking, cohesion) that will be experienced by a consumer or user.

The examples below show industries where powder flow knowledge is known to be of major significance with highlights of academic that has also been published in this field. These are just some application and operation areas where commercial advantage, profit, and product performance within these and similar industries can be enhanced by an improved knowledge of powder flow.

Food ingredients

Welcomed by all sectors of the food industry, Powder Flow Analysis allows accurate and objective testing of ingredients, blends and finished products, as diverse as lecithins, flours, coffee granules, drinking powders, sugar, sweeteners, spices, pulses, salt, seasonings, herbs and milk powder.

View examples of published work: Banana Powder Production, Ready-to-use Powdered Dessert and Coffee Powders

Pharmaceutical powders

Objective and repeatable testing combined with ranking of dry powder samples can provide significant opportunities and benefits. These include optimising batch and source selection in terms of cost and quality; the development of best mix formulations; optimising scaling up and process conditions; and maintaining product quality control. Innovative technology provides such data either by measuring and comparing products capable of flow, or by assessing sample behaviour under test conditions simulating in-process or product handling conditions. Best-practice raw material purchasing, processing efficiency, waste minimisation and product quality – before and after storage, packing and transportation – are all desirable for manufacturers. The application of practical powder rheology is a valuable tool for achieving these goals.

Grain products

Some of the most common powder handling problems arise when conveying from storage silos or bins into production. Often the powder or grain will have been motionless for hours, days, or even weeks before flow is required. Over this time, most powders or granules will compact with the result that far more energy is needed to cause flow than in aerated samples. On the other hand, powders used immediately after transport, which may have involved agitation or more pronounced vibration, will have been aerated and flow more easily than others that have been stored. Cornflour, Couscous, Flour (white), Flour (wholemeal), Oatbran, Polenta, Rice (flaked), Tapioca and Wheatbran.

View examples of published work: Tef grain powders and Commercial Rice Flour/Powder

Cleaning and washing products

As costs are required to be driven down, the substitution of expensive constituents with lower cost powders is an attractive prospect. Although these substitutes may be produced to the same specification as the original substance, they may not necessarily store, convey and process as easily. Discovering this after production of materials such as detergents has started would incur downtime and additional cost. Final product quality may also be compromised.

Nuts, seeds and pulses

In these products, many common manufacturing problems are attributed to powder or granule flow, including segregation, inaccurate filling of packaging, obstructions and stoppages. These in turn lead to machine downtime and defective end-products. Storage, handling, production, packing, distribution and end use can all be negatively affected by common powder/granule flow problems.

Personal care powders

The PFA is particularly welcomed by the pharmaceutical and cosmetics industries as it allows objective testing of ingredients, blends and finished products, from eye shadows and foundations to gels and face powders, baby powder, bath salts, denture cleanser, face powder, foot powder, protein powder and slimming powder. Product development teams can evaluate the flow properties of new excipients, active ingredients and formulations, predicting their behaviour prior to commencing large-scale production. They can also check how new powders interact with existing constituents. This speeds up development time and minimises “trial and error” tactics, especially important when certain ingredients are extremely valuable and may have only been produced in small quantities.

Building and decorating materials

Many common manufacturing problems are attributed to powder flow, including non-uniformity (segregation) in blending, under- or over-dosage, inaccurate filling, obstructions and stoppages. These in turn lead to rejected material, machine downtime and defective end-products. Storage, handling, production, packing, distribution and end use can all be negatively affected by common powder flow problems. These materials include cement, interior filler, plaster, sawdust, sugar soap, tile grout, wallpaper adhesive and paint.

Garden products, agrochemicals and animal feed

Handling and processing powders, particulates and granules is central in product processing, but has traditionally been fraught with problems due to their unpredictable and irregular behaviour, specifically with respect to flowability. With so many raw materials and semi-finished products in powder form, such as bird sand, grass seed, insect food, Nyjer seed, herbicides, pesticides and plant fertiliser, this sector stands to gain significant manufacturing and commercial benefits from improvements in the assessment of powder flow.

The above highlights just a few industries and their typical powder flow issues but the list is exhaustive and also includes such examples as:

- Abrasive and fine powders: : Diamond, ceramic, and metallic powders and pastes for grinding, polishing, magnetic recording tapes

- Ceramics: Powder and wet mix for extrusions

- Energy: Coal and other powdered fuels, nuclear fuel granules

- Metallurgy: Iron and steel powders, quartz, ore, sintered powders

- Paint: Pigments, fillers, binders (titanium dioxide)

- Toner: As used in photocopiers

We don`t just measure powder flow – we have the complete testing solution from start to finish.

Beneath your Powder Flow Analyser lies a texture analyser – extending your testing possibilities dramatically.

When coupled with a Powder Flow Analyser, the TA.XTplusC Texture Analyser gives you a complete range of testing solutions for both your powders and end-products making it the most universal instrument choice.

Within the same instrument, users can experience an extensive set of well-established testing possibilities such as Unconfined Yield Stress, uniaxial compression with the Powder Compaction Rig, diametral tablet compression using Cylinder Probes and granule compressibility using a Granule Compaction Rig.

Single particle mechanical strength and progressive swelling/disintegration of granules and pellets also expand the myriad of tests available for samples from powder to finished product. Alternative powder flow measurements do not provide such a comprehensive range of testing possibilities.