- Home

- Companies

- Stable Micro Systems Ltd

- Products

- Stable Micro Systems - Model Volscan ...

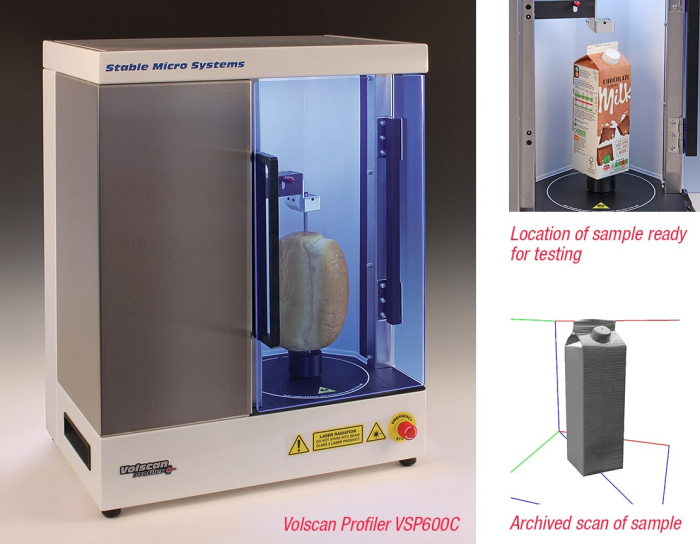

Stable Micro Systems - Model Volscan Profiler -Measure Volume, Density & Dimensional Profiles

The Volscan Profiler is a benchtop laser-based scanner that measures the volume, density and dimensional profiles of solid products.

Measure more than volume

The rapid 3-dimensional digitisation of products enables the automatic calculation of volume, density and dimensions of solid products as standard. Additional measurements include surface area, height, width, length and weight etc. The results may then be mathematically manipulated for immediate use or future retrieval in a variety of data formats.

Fast and accurate

In as little as 22 seconds manufacturers have precise data about their products in order to control and monitor their production.

World class data analysis software

Our powerful, feature-rich software comes as standard. Best of all, free updates are included for the lifetime of your instrument. Find out more

More accurate than the outdated seed displacement method

Traditionally, volume measurements of baked products have been obtained by the technique of seed displacement, in which the amount of rape seed or pearl barley packing around the loaf in a standard container is measured. Whilst this method has been universally recognised for decades as indicative of baking quality, it is now considered primitive, inaccurate, tedious and laborious. Repeated calibration, operator dependence, loss of rapeseed due to spillage/adherence of seeds to the product or to static electricity, seed clumping due to moisture absorption, periodic sieving of the seed to remove food crumbs, the potential crushing of soft products and the manual recording of results are the common drawbacks affecting both the efficiency and the accuracy of the measurement.

Besides offering rapid 3-dimensional digitisation of products, it has the ability to measure objects that, due to their texture or size, was not possible with seed displacement. Soft, thin or brittle products with vulnerable structure due to toppings, or being easily altered by the compressive nature of seed displacement are easily mounted on theVolscan Profilerby a variety of supporting pins.

Safer than alternative/outdated methods

Mercury displacement techniques represent a toxic risk to the environment and are therefore illegal in many countries. TheVolscan Profilerhas been verified as accurate as mercury displacement method.

X-ray techniques are expensive and present a health and safety issue and therefore require fully trained operators. TheVolscan Profileruses an eye-safe laser and therefore is the safest procedure for density determination.

More versatile than other methods

Fluid displacement techniques are not suitable for porous materials. TheVolscan Profileris a non-contact laser-based measurement that is not affected by sample porosity.

Gas displacement techniques usually measure very small samples or otherwise attract a high instrument price. TheVolscan Profilerhas the largest measurement envelope in its class.

Fully rotatable test files

Appreciate the scan detail in every plane. The scanned data can be viewed in both 2D and 3D representations to allow comparisons with previous archived measurements. Within the 2D sectional view, additional manual measurements can be made on chosen intervals. 3D views of the product are rotatable in all planes providing flexibility of viewing for visual comparison and presentation.

Choice of Rotation Speed

For heavy soft samples (e.g. sandwich cake) or delicate samples, the centrifugal force created during the rotation can distort the sample or cause it to fragment or wobble and therefore a slower rotational speed is recommended. The fast speed provides the quickest scan times, but can affect the integrity of some products and produce less accurate results.

Stacking products for faster testing

By customer request, we have implemented a means of testing multiple products simultaneously, followed by post-test analysis of the data of each sample piece. One such example is in the testing of multiple bread rolls, the objective being to save time, to give an average volume and weight and then create individual scan files of each roll.

Easy verification

A measurement is only worth performing if it’s accurate. Check and verify yourVolscan Profilereasily by testing a Calibration and Verification Rod. The instrument will verify that the rod correlates with the measurement values as provided by the manufacturer so that product testing can continue with confidence.

Testing bakery products? Use the AACC Standard Method 10-16.01

The highest accuracy and more scope in parameters and breadth of bakery samples than any other method. Why measure volume alone when we’ve proven the accuracy of measurement of a wider set of product dimensions? If you’re in the bakery industry this is the standard method that you will wish to follow. Find out more

All of your data in one place

Provided by a built-in spreadsheet for data collection and statistical manipulation. There is no need to export data to another spreadsheet program, as theVolscan Profilersoftware has its own integral spreadsheet, but Exporting to Excel is also an available option if preferred.

Presentation of results

A report template is available into which your data can be dropped and automatically positioned with test data fields or modified using full Report Editing tools. Alternatively, images and data can be copied and pasted into other applications.

Operate in another Language using the Language Editor

Menu items and operator messages can be easily converted into your own language using a provided plug-in tool for language editing.

Barcode Scanner compatibility

Allowing quick product information entry and reducing user error. This device attaches via the USB port on a PC.

- Determine the effects of ingredients, formulation or processing variables on end product dimensions

- Determine the dimensional properties of your ‘gold standard’ product for future consistent quality control

- To assess dimensional changes during storage or transportation

- Substantiate your product claims

- Compare with competitive products

- Provide an objective quantifiable result which can be archived and retrieved for future viewing should you ever need to check back and compare with historical data.

- Globally recognised instrument

- World class data analysis software

- Widest range of probes, fixtures and accessories

- Complimentary software updates for the life of your instrument

- Complimentary technical support

- Unrivalled inbuilt test advice library

- Extended warranty

- Bespoke test solution service

- Over 10 years expertise

The instrument of choice for leading companies and universities across the globe

While our consumers are aware that our instrument is the best in the world, their decision to purchase one is not just based on the hardware. Ultimately, it all comes down to the service we provide to all of our customers. When considering the purchase of a laboratory instrument, our clients consistently cite our experience and desire to assist them with testing issues of all shapes and sizes as the number one reason why a Stable Micro Systems instrument is, and will always be, their first option.

Further information Buying advice

Read our guide Seven Tough Questions you should ask before buying a Volume Measurement Instrument

Case Studies

Explore our case studies to see how our customers have used their instruments to further their testing requirements and find solutions to testing problems.

Learn what aVolscan Profileris and how it is applied for dimensional measurement.

The Volscan Profiler is a benchtop laser-based scanner that measures the volume, density and dimensional profiles of solid products.

Operational overview

TheVolscan Profilerscans test samples using an eye-safe laser to produce the fundamental measurements of volume, density as well as other measurements including surface area, height, width, length and weight which are then available for analysis in the feature-rich software.

Preparing and running a typical test

The product is speared at each end or located by a suitable mounting device tailored to the specific product. Parameters for each batch under test, which are entered into the software by the operator, include: sample ID name and date. The product is then automatically weighed and an eye-safe laser device is used to scan vertically to measure the contours of the product at selectable intervals whilst it rotates.

Each interval consists of 400 data points providing a detailed profile of the product. This assessment can be done rapidly, the results being obtained in a period ranging from a few seconds to a few minutes depending upon the chosen interval (0.05mm to 50mm) and the preferred precision. Temperature of the testing chamber can be measured automatically.

For every product scanned the following information is automatically calculated and displayed alongside the 2D and 3D scans:

Weight, Specific Volume, Volume Yield, Product Density, Length, Surface Area, Max Height, Width at Max Height, Aspect Ratio at Max. Height, Max Width, Height at Max. Width, Aspect Ratio at Max Width, Height of Middle Slice, Width of Middle Slice, Aspect Ratio of Middle Slice, Minimum Enclosing Circle, Max Inclusive Square Volume, Trim Percentage, Circumference, Area of Maximum Projection, Largest Radius, Frizziness, Symmetry, Surface Texture.

A full guide is available in Help File format to assist in setting up and performing tests, explaining the calculations and advising on optimum test settings to suit your product.

Step-by-step video tutorials

The Volscan Profilercan be used according to the AACC Standard Method: Volumetric and Dimensional Profile Determination of Baked Products using Laser Topography – Volscan Profiler Method – 10.16.01. To follow the steps of this method watch our video

If you’re looking for a great demonstration of how a Volscan Profilerworks given by an expert from University College Birmingham (UCB) Bakery and Patisserie Technology which explains how to get testing your products, watch this video. UCB is renowned for its outstanding food industry training facilities and trains specifically in the field of bakery and patisserie technology.

Using theVolscan ProfilerandCeramscan– safe, accurate, non-contact laser-based methods.

Why measure volume?

There are many specific instances where volume is required as a quality control indicator and therefore is required to be measured. In the baking industry, for example, loaf volume is the most important factor to consider when evaluating bread quality. Higher volume – for the same weight – is generally associated with more aerated crumb and greater texture in bread and other leavened items, hence this is an important part of the consumer`s impression of value.

Volume is also an important physical property of agricultural products, meats and packaging. When compared to other industrial commodities, agricultural products have a low value added attribute. As a result, the introduction of cutting-edge technology to the agricultural sector has been slow and several cutting-edge techniques such as laser profiling have only recently reached the stage of practical implementation.

The majority of traditional techniques measure volume using the Archimedes principle of displacement whilst new technologies lend themselves to non-contact methods. Here are a list of reasons for using a laser-based principle:

- Fluid displacement techniques are not suitable for porous materials. The Volscan Profiler/Ceramscan is a non-contact laser-based measurement that is not affected by sample porosity.

- Mercury displacement techniques represent a toxic risk to the environment and are therefore illegal in many countries. The Volscan Profiler/Ceramscan have been verified as accurate as mercury displacement methods.

- Gas displacement techniques usually measure very small samples or otherwise attract a high instrument price. The Volscan Profiler/Ceramscan has the largest measurement envelope in its class.

- X-ray techniques are expensive and present a health and safety issue and therefore require fully trained operators. The Volscan Profiler/Ceramscan uses an eye-safe laser and therefore is the safest procedure for density determination.

Why measure density?

Density measurements are required in the production of many modern items. It is a highly important and dependable measurement for characterising the structure and quality of solid materials, such as catalysts, ceramics, foams, minerals, metal powders, soils, cement, pharmaceuticals, and many others, swiftly and routinely. Density measurements influence the overall quality of manufactured products by guiding the formulation process.

It is frequently advantageous to reduce the weight of products while preserving the overall physical size of the product for performance or cost-cutting reasons. In reality, manufacturers often try to create somewhat porous materials that still perform their technological functions. The existence of closed air bubbles in items like house insulation materials is desirable. The open cellular structure of automobile and furnace filters, on the other hand, is required. Other goods, such as ceramics and laminate structures, require the suppression of porosity to maintain structural integrity.

The density of a material, when paired with other data, might reveal plausible causes of changes in product attributes. A change in density can be caused by a fault or by a change in material composition (such as a void in a casting). This can aid quality control; at aluminium foundries, for example, the purity of a melt can be established by comparing the relative densities of a part formed under air pressure and a part formed under low pressure.

The density of porous materials is affected by the quantity and size of pores. The porosity affects other material qualities, so its accurate measurement is very important. For example, the frost resistance of roof tiles or the properties of wall materials such as concrete are affected by porosity, and in turn, density as is the burning potential of charcoal briquettes.

Why measure product dimensions?

Many manufactured parts need to be dimensionally accurate. Vernier callipers are frequently used to measure product dimensions. While this method provides a digital way of measurement, it frequently entails operator dependence, which can lead to an incorrect result.

As a modern example, when you design a product in a CAD programme and then print it, one of your concerns will be whether what was printed matches what you intended. In many circumstances, you`ll need your printed object to be dimensionally exact, and iterations of printing your design to modify the printing settings to get a dimensionally accurate outcome are almost inevitable. As a result, accurate digital measurement of physical dimensions becomes a requirement.

TheVolscan ProfilerandCeramscanare benchtop laser-based scanners that provides such a solution, measuring the volume, density and dimensional profiles of solid products. The rapid 3-dimensional digitisation of products enables the automatic calculation of several detailed dimension related parameters, the results of which may be mathematically manipulated for immediate use or future retrieval in a variety of data formats for your printed objects.

The Volscan Profiler is a benchtop laser-based scanner that measures the volume of bread and bakery products.

Which Volscan Profiler model should I choose?

The model you choose will be based solely on the size of the products that you wish to measure and therefore fit comfortably into the instrument.

Technical Summary

Sample Dimensions: VSP600 (VSP300)

- Max diameter: 380mm (190mm)

- Max height: 600mm (300mm)

- Max sample weight: 3kg (3kg)

Movement and Measurement:

- Variable scanning resolution

- Volume accuracy: ± 1% (± 1%)

- Minimum test time for 150mm product: 38 seconds (based on a 10mm step size, 1.5rps and 99% accuracy and constant ambient temperature)

- Rotational speed options: 0.5 / 1.0 / 1.5rps

- Data acquisition: 400 points per revolution

- Vertical step size options: 0.05mm - 50mm

- Sample weight accuracy: <1%

Dimensions: VSP600 (VSP300)

- Instrument weight 41kg (25kg)

- Overall height 939mm (639mm)

- Overall width 690mm (490mm)

- Overall depth 480mm (355mm)

Mechanical:

- Simple calibration

- Door interlocking mechanism for additional safety - tests cannot be started unless door is closed

- Universal Product Support - alternative support solutions with user selected pin array

- Product Support for Disposable Inserts

Electrical:

- Operating temperature: 10° - 40°C (non-condensing)

- Ambient temperature measurement recorded automatically

- Universal mains input voltage: 100-240 V AC 50/60Hz

- Connectivity: USB

Optional Additions:

- Universal Product Support

- Calibration and Verification Rod

- External Precision Balance – option of communication with external precision balance (that can transmit displayed values as an ASCII string) via PC COM port

Typical PC Requirements:

- 2.5 GHz modern Intel 32 bit or 64 bit Multicore CPU or AMD equivalent

- 4 GB memory

- 2 GB free hard disk space

- OpenGL or DirectX 9.0c compatible graphics card

- Supported operating systems: Windows 10 and 11

The latest software versions are available to download free of charge.

The Volscan Profiler is complementary to Stable Micro Systems` wide range of texture analysis solutions which are developed and manufactured in-house and supported by a qualified technical applications team and international distribution network.

View a range of optional extras that are available for the Volscan Profiler.

Calibration and Verification Rod

A measurement is only worth performing if it’s accurate. This is why you’ll want to have control of instrument calibration and the means of verifying that the instrument is measuring accurately by testing with a ‘known dimension’ tool called a Calibration and Verification Rod.

The instrument will verify that the rod correlates with the rod’s calibration certificate which provides dimension measurement values obtained using certified dimension measuring tools. You can then continue your product testing feeling confident that your instrument performance has been checked.

The Universal Product Support*

As the Volscan Profiler provides the largest sample testing envelope in comparison to other laser volume measuring instruments, the scope of potential test samples extends much wider.

The choice and configuration of spikes and skewers for product support depend on the dimensions and texture (e.g. brittleness, softness), weight, centre of gravity and contact area with the base. The aim is to provide vertical stability without damaging the sample structure and thereby allowing an accurate measurement of its dimensions and volume to be recorded during the test.

The Universal Product Support is an optional accessory which extends the range of products which can be held within the instrument in order to be successfully tested. It provides a myriad of support solutions by presenting a 100mm diameter base with an array of pins of differing thicknesses and lengths.

The choice and arrangement of spikes and skewers depend on the dimensions and texture (e.g. brittleness, softness), weight, centre of gravity and contact area with the base. The aim is to provide vertical stability without damaging the sample structure and thereby allowing an accurate measurement of its dimensions and volume to be recorded during the test.

This Community Registered Design by Stable Micro Systems continues the expansion of product testing and analysis opportunities for the Volscan Profiler – a continuous development and improvement process which applies to all of Stable Micro Systems products.

*Community Registered Design

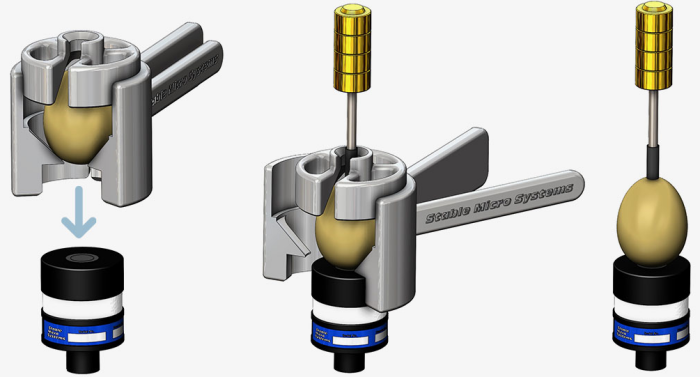

Weighted Sample Supports

There is an additional range of options for mounting those samples that require vertical support for testing that cannot be pierced with the standard product support mounting pins.

Samples are held in place by the support of a weighted shaft and the addition of user-replaceable mini glue dots. A choice of support solutions (caps) are included in the kit depending upon the sample to be supported. The chosen cap is mounted on the end of the shaft which has a 50g weight fixed to the shaft. An additional 50g and 3 x 50g weights are provided as options depending upon the support required.

This solution has been found particularly useful for supporting eggs to be scanned and has also been found to be perfect for other samples such as rocks and hard chocolate where it is again not possible to insert pins into the sample in order to support them.

Egg Aligner

In order to mount eggs with perfect vertical alignment, we have also developed a device that holds eggs of varying size (from large quail to small duck) and presents the sample to the supports. This is necessary if accuracy of shape and dimension measurement is important as a sample that is misaligned will result in compromised results.

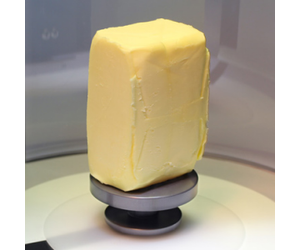

Sample Platform for Disposable Inserts

Disposable sample platforms provide the means to adhere samples to the platform and allow for quick removal and replacement between tests. They are located via a magnet and provided in batches of 50 which be reusable, according to the chosen adhesive.

Precision Weight Measurement

For many sample types, the instrument can measure sample weight to an acceptable degree of accuracy. However, for very light samples requiring a weight measurement with higher precision (e.g. to 3 decimal places), users now have the option to attach their own balance.