- Home

- Companies

- Delphin Technology AG

- Products

- Delphin - Model ProfiMessage D - ...

Delphin - Model ProfiMessage D -Measuring Device for Modular and Flexible Data Acquisition

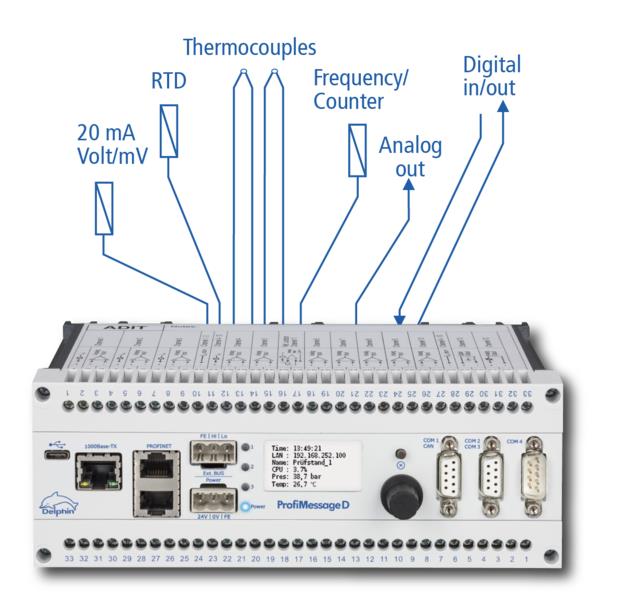

With the ProfiMessage D device, you can use a PROFIBUS interface and communicate with external systems via OPC UA Server/Client. A display allows you to read important configuration data and measured values. Its hallmarks are the universally applicable sensor inputs, high data security and versatile interfaces.

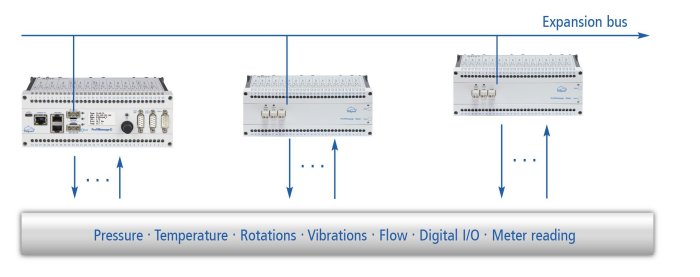

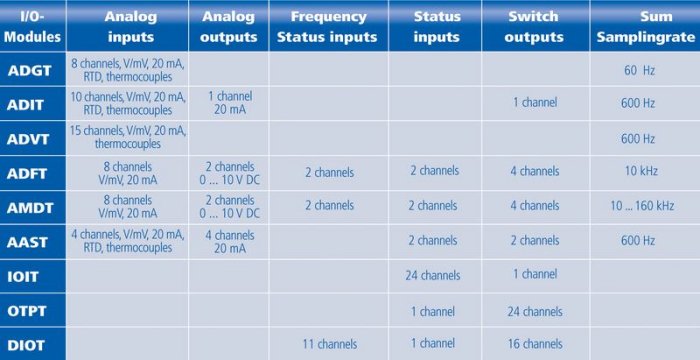

The device utilises faster processor technology to provide the resources needed to realise any application. Its modular design is based on the use of master and slave devices. These can be equipped with one or two I/O modules. A large number of I/O modules means systems can be adapted to different sensor types as well as to the number of channels required. The I/O modules are equipped with 8–24 analog or digital inputs and outputs. In addition to these modules, a range of fieldbus interfaces are also available. Easy connections are possible to PLC control systems for data exchange purposes. With such a diversity of features and functions offered by ProfiMessage D devices, you gain instant benefits:

- Cost savings – just one system for measuring, monitoring and automation

- Time savings – easy to configure and practical to use

- Compatible for future needs – with OPC UA, ready for the IoT

ProfiMessage D enables you to easily develop applications according to your requirements, whether for measuring processes at machines, systems or test stands.

Independent data recording

ProfiMessage D devices record measurement data independently to an internal data storage capability of up to 32 GB, large enough for several billion measurement values including precision time stamps. A USB interface is available to extend the data storage capability via a USB stick.

Measurement data can be instantly read out online via an Ethernet interface during runtime. This can be performed manually on request or automatically according to a set time schedule. For stand-alone, network-independent operation, recorded measurement data can be transferred at the press of a button to a USB device for offline analysis.

Integrated IoT compatibility

Connecting a ProfiMessage D device to the cloud is possible for a range of application scenarios. Online measurement data can be transferred to a PC connected to the internet. The PC can then be used to access both current and historical data and to portray such data in trends (online applications). If the ProfiMessage D device is used as a stand-alone device for recording measurement data, the data can be automatically and regularly transferred to a cloud drive (offline applications). The data can then be accessed from the cloud and evaluated offline using the ProfiSignal software.

In online applications, the DataService software, which creates the connection to the ProfiMessage D devices, is run on a server in the cloud. Connection of the ProfiMessage D devices to the cloud takes place wirelessly via LAN/WLAN – secured via VPN. The required services, such as user authentication from a ProfiMessage D device, is provided as standard.

The DataService saves the measurement data to a database on the cloud server, and provides both online and historical measurement data for ProfiSignal trend diagrams. To set up such a solution requires a cloud server to enable the running of the DataService. The cloud server can be a server on the internet, a server on a company network, or a standard local PC.

Offline applications require only cloud-based server storage resources. The ProfiMessage D is connected to the internet via LTE or LAN/ WLAN and transfers its off-line measurement data using FTP, CIFS or NFS. When required, transfer to the server can also be made via a VPN. Users can download files from the cloud server and evaluate data off-line using ProfiSignal.

Diverse fieldbus interfaces

The variety of ProfiMessage D interfaces makes it very easy to communicate with external systems. Regardless of whether data needs to be exchanged with a PLC, a frequency inverter or an intelligent field device, setting up the interfaces and data exchange is very easy to understand.

The LAN interface transmits all measurement data at high speed across an intranet or the internet. Any networked PC can access a ProfiMessage D via this interface. Other TCP services such as NTP, SFTP, HTTP and SMTP are supported. Internally stored data can also be read out via the LAN.

These serial interfaces can function with individual and proprietary protocols. The protocols can be created either directly by the user or by Delphin. Applications include the control of climate chambers, laboratory devices, power measuring units and GPS reception.

The CAN bus interface can be programmed as required. Any identifier can then be read, scaled, processed and recorded.

All Expert devices are equipped with an OPC UA Client/Server interface. This equips the ProfiMessage D series devices for universal measurement-data exchange at field level and therefore meets Industry 4.0 requirements. Measurement data and threshold violations can be immediately transmitted to subsystems via OPC UA. The OPC UA interface also provides data exchange to PLC systems and connections to process management systems.

The USB interface (type C) can be used to read out the internally stored data to a USB data stick or connect a PC.

The LAN and RS485 interface can exchange data via Modbus TCP/RTU. ProfiMessage D supports this operation as a Modbus master or slave.

ProfiMessage D also has two separate PROFIBUS DP slave interfaces and is integrated into PROFIBUS via a GSD file. Any analog or digital signal can then be read or written to from PROFIBUS. There is the option to switch operating mode to redundant PROFIBUS (according to PNO 2.212 V1.2).

The expansion bus enables up to 20 slave devices to be connected to the master device.

Here you will find an overview of the standard and optional hardware interfaces and protocols Learn more about the variety of interfaces of our measurement technology software.

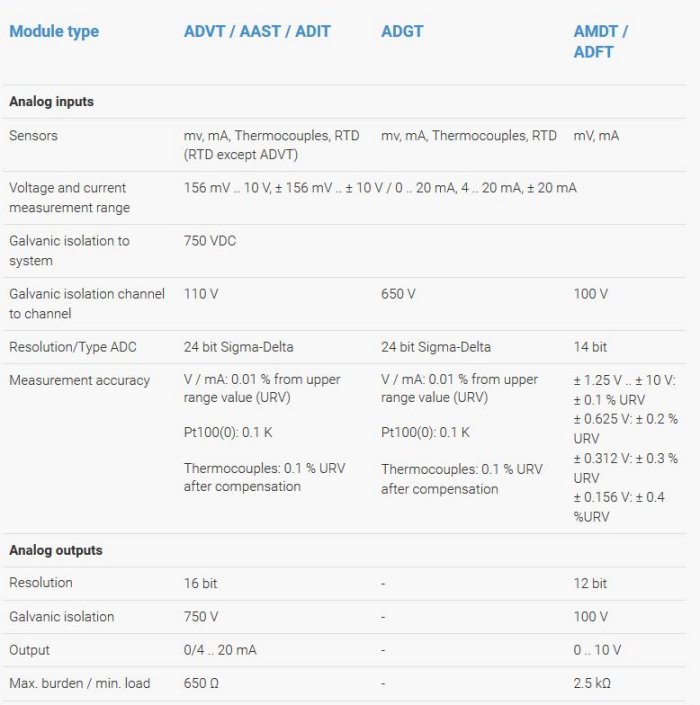

Depending on the I/O module being used, each input can be individually configured for measuring mV, mA, RTDs and thermocouples. Universal inputs for voltage, current and temperature measurement make ProfiMessage D devices extremely flexible. Digital inputs are also available as status or frequency inputs, as well as digital and analog outputs.

A major advantage of ProfiMessage D devices is that the inputs and outputs are differential, high-precision and galvanically isolated – from each other and from the power supply. Earth loops are effectively suppressed. A unique system architecture also enables problem free measuring of non-isolated sensors

ProfiMessage D devices are equipped with a display operated via a jog wheel. The display enables important network settings to be made such as the IP address and net mask. Current measurement values can also be displayed.

Easy and effective configuration

ProfiMessage D configuration takes place with the Configurator software that is included in delivery. It portrays channels clearly, and operation is intuitive and simple, similar to that of the Windows Explorer. Double clicking a channel opens a configuration dialog to enable users to set the channel properties. The individual configuration files are stored within the ProfiMessage D devices in XML format

Device configurations can be read out from a ProfiMessage D device and stored separately. Configurations can then be easily changed to make it easy to use one device for different purposes. Offline configuration is also possible. No online connection to the ProfiMessage D is then required.

- Modular measurement data acquisition

- Monitoring systems

- Process data acquisition and preprocessing

- Fault-data acquisition and fault diagnostics

- Acquisition, processing and recording of PLC and field bus signals

- Automation device for experiments and test stands

- Remote monitoring device for plant and machinery

- Laboratory measurement acquisition and automation

Flexibility for any sensor or actuator

Depending on the I/O module being used, each input can be individually configured for measuring mV, mA, RTDs and thermocouples. Universal inputs for voltage, current and temperature measurement make ProfiMessage D devices extremely flexible. Digital inputs are also available as status or frequency inputs, as well as digital and analog outputs.

A major advantage of ProfiMessage D devices is that the inputs and outputs are differential, high-precision and galvanically isolated – from each other and from the power supply. Earth loops are effectively suppressed. A unique system architecture also enables problem free measuring of non-isolated sensors.

ProfiMessage D devices are equipped with a display operated via a jog wheel. The display enables important network settings to be made such as the IP address and net mask. Current measurement values can also be displayed.

Optional WLAN interfaceProfiMessage D is optionally available with a WLAN interface. Configuration is possible as a WLAN Client or ACCESS Point. When the WLAN option is selected, an SMA antenna connecting point is located on the front of the device.

Configuring ProfiMessage D is highly intuitive, quick to learn and user-friendly whether for setting up an analog input for temperature measurement or a limit value for a switchable output. Such tasks can be performed within just a few mouse clicks.

ProfiMessage D configuration takes place with the Configurator software that is included in delivery. It portrays channels clearly, and operation is intuitive and simple, similar to that of the Windows Explorer. Double clicking a channel opens a configuration dialog to enable users to set the channel properties. The individual configuration files are stored within the ProfiMessage D devices in XML format.

Device configurations can be read out from a ProfiMessage D device and stored separately. Configurations can then be easily changed to make it easy to use one device for different purposes. Offline configuration is also possible. No online connection to the ProfiMessage D is then required.

ProfiMessage D master and slave devices can each be equipped with up to two I/O modules. A single master device can be connected with up to 20 slave devices of the same housing designs. Data exchange between master and slaves takes place via a real time expansion bus using robust dual-wire technology.

Slave devices can be decentrally located and managed from a single master device. Nine different I/O modules are available for ProfiMessage D devices. Each master or slave device can be equipped with two I/O modules. When a master device is intended to process fieldbus signals only, it can be supplied without an internal I/O module.

Test stands frequently need to acquire combined vibration and process measurement data from rotating machinery (e.g. pumps, drives, motors, compressors). Such tasks can be performed using ProfiMessage D devices in combination with time-synchronized Expert Vibro or Expert Transient devices. Such combinations enable extremely slow measurement values to be acquired, recorded and analysed, along with measurement values of up to 50kHz.

Diverse fieldbus interfaces

The range of ProfiMessage D interfaces makes it extremely easy to communicate with external systems. Setting up interfaces and exchanging data is simple whether for a PLC, frequency converter or intelligent field device.

The number of ProfiMessage D interfaces has been further extended compared to its predecessor model. In addition to PROFIBUS, a optional PROFINET interface is now available. There is also an option for WLAN.

LAN/TCP

The LAN interface transmits all measurement data at high speed across an intranet or the internet. Any networked PC can access a ProfiMessage D via this interface. Other TCP services such as NTP, SFTP, HTTP and SMTP are supported. Internally stored data can also be read out via the LAN.

OPC UA

All Expert devices can be optionally equipped with an OPC UA Client/Server interface. This equips the ProfiMessage D series devices for universal measurement-data exchange at field level and therefore meets Industry 4.0 requirements. Measurement data and threshold violations can be immediately transmitted to subsystems via OPC UA. The OPC UA interface also provides data exchange to PLC systems and connections to process management systems.

PROFINET (optinal)

ProfiMessage D supports different PROFINET topologies, e.g. ring, line and topologies, while adhering to the CC-B conformance class.

PROFIBUS

ProfiMessage D also has two separate PROFIBUS DP slave interfaces and is integrated into PROFIBUS via a GSD file. Any analog or digital signal can then be read or written to from PROFIBUS. There is the option to switch operating mode to redundant PROFIBUS (according to PNO 2.212 V1.2).

Modbus TCP/ RTU

The LAN and RS485 interface can exchange data via Modbus TCP/RTU. ProfiMessage D supports this operation as a Modbus master or slave.

RS232/RS485

These serial interfaces can function with individual and proprietary protocols. The protocols can be created either directly by the user or by Delphin. Applications include the control of climate chambers, laboratory devices, power measuring units and GPS reception.

CAN bus

The CAN bus interface can be programmed as required. Any identifier can then be read, scaled, processed and recorded.

USB interface (master/slave)

The USB interface (type C) can be used to read out the internally stored data to a USB data stick or connect a PC.

Expansion bus

The expansion bus enables up to 20 slave devices to be connected to the master device.

Monitoring and automation tasks are performed independently by the ProfiMessage D device using software channels.

Software channels are predefined function modules that users set up, configure and process within the device by mouse clicking. For example, computations can be performed on measurement via calculation channels. Limit-value channels monitor measurement data and issue alarms and dispatch emails in the event of an alarm.

There is practically no limit to the number of available software channels. All functions are independently processed by the powerful internal processor and ensure fully secure operation of the ProfiMessage D device.

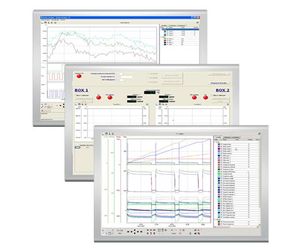

The ProfiSignal software from Delphin is recommended as the optimal accompaniment to ProfiMessage D devices and provides secure and easy recording of all measurement data. It is designed for both small and large numbers of channels and is highly practical for evaluation tasks.

The tool offers the choice of an extensive range of diagram types and provides a diverse range of additional alarm and monitoring functions. The ability to process large volumes of data and a range of interfaces and drivers makes ProfiSignal a very powerful tool.

ProfiSignal is available in four different versions and therefore suitable for a range of applications:

ProfiSignal GoProfiSignal Go enables you to portray online data from Message and Expert hardware in diagram format. Numerous analysis functions such as zoom, cursor, movable axes, markers, ASCII export and calculation channels enable fast measurement-data portrayal and post-processing.

ProfiSignal BasicProfiSignal Basic combines ProfiSignal Go functions with operating and monitoring elements for process visualisations, e.g. digital and analog displays, switches, buttons and signal lamps. The software enables you to create simple visualisation tasks as well as complex visualisation systems.

ProfiSignal KlicksProfiSignal Klicks adds process-automation functions to ProfiSignal Basic. Processes can be portrayed as structure charts and a script language (fully operable per mouse) enables even those without specialist IT knowledge to create complex test stand and automation applications including automated report generation.

ProfiSignal WebWith the new add-on ProfiSignal Web, it is possible to access not only current measurement series and process parameters, but also historical measurement data, regardless of location. The display is in to customizable dashboards easily in the browser of any terminal.

Digital inputs

- Galvanic isolation: 2.5 kV

- Input measurement range: low: 0 .. 1.5 VDC@0 .. 1.5 mA / high: 3.5 .. 90 VDC@2.5 .. 3 mA

Frequency / counter inputs

- Galvanic isolation / input measurement range: 2.5 kV / low: 0 .. 1.5 VDC@0 .. 1.5 mA / high: 3.5 .. 90 VDC@2.5 .. 3 mA

- Measurement frequency: up to 30 kHz (DIOT), up to 50 kHz (AMDT, ADFT)

Digital outputs

- Potential isolation: 2.5 kV

- Switching voltage: max. 50 VDC@2.5 A

Data storage

- Internal: 2 .. 14 GB (approx. 40 million measurement values per GB / 300 million measurement values per GB for AMDT, ADFT)

Interfaces

- Physical equipment COM 1 / COM 2: RS485, 9-pole sub-D-socket, IEC 61158-2

- Physical equipment COM 3 / COM 4: RS232, 9-pole sub-D-socket (COM 3), 9-pin sub-D plug (COM 4)

- Protocols COM 1 / COM 2: PROFIBUS DPV1 Slave (both interfaces), also redundant according to PNO 2.212 V1.2

- Protocols COM 1 .. COM 4: Modbus RTU master / slave, customer-specific protocols, ASCII

- Ethernet: RJ45 (8-pole STP-socket), 1000Base-T; Protocols: TCP/IP, HTTP, SMTP, NTP, Modbus TCP and OPC UA client / server

- PROFINET (optional): 2 x RJ45 (8-pin STP socket) for any topologies; conformance class CC-B; ring redundancy MRP

- WLAN (optional): 802..11 b/g

- USB: USB 2.0 type c for configuration and data memory read out

- CAN: 9-pole sub-D-socket, Protocols: CAN, RAW; baud rates: 50 k .. 1 MBaud; dbc-import possible

- Module bus baud rate / length: 1 MBaud / 10 m .. 25 kBaud / 100 m

General technical information

- Dimension / weight: 200 x 73 x 120 mm / 1 kg

- Fixing: Rail mounting DIN EN 60715 or screw fixing

- Signal connections: Detachable screw terminals, 33 terminals in 2 rows, lead protection, connecting cabling max. 2.5 mm²

- Display: 7 lines, operation via jog wheel

- Temperature range: -20 .. 50 °C

- Humidity: max. 90 % relative humidity, non-condensing

- Power supply: 12 .. 24 VDC ± 10 %

- Power input: < 10 Watt