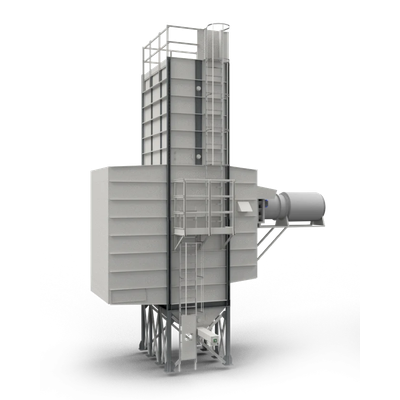

Mecmar - Mixed Flow Batch Dryer

The mixed flow batch dryers in Mecmar’s MB series are designed to provide high-efficiency and productivity solutions for the grain drying process. Ideal for drying between 20 and 200 tons of grain per day, with a capacity ranging from 60 to 120 tons in 24 hours for corn, reducing moisture from 35% to 15%. These plants offer numerous advantages, including low installation costs and high energy efficiency, with the option to integrate insulation for improved heat retention. Additionally, they ensure low noise emissions and minimize dust dispersion into the environment, contributing to a reduced environmental impact.

Designed for batch operation, the MB dryers follow a process that begins by loading the product to be dried into the top of the drying column until the reserve section is filled. Then, the burner and fan are activated to remove moisture from the grain. Once the desired moisture level is reached, the burner is turned off, and the product is cooled before the final discharge. At the base of the drying column, a pulsed pneumatic extractor enables the recirculation of the product, allowing for either automatic or manual discharge of dried or cooled grain. By adjusting the frequency and duration of discharge pulses, it’s possible to control the target moisture level and the dryer’s production capacity, providing high flexibility to meet specific customer needs.

The mixed flow batch dryers in the MB series are ideal for drying between 20 and 200 tons of grain per day. They operate in batch mode: the drying cycle for a batch is carried out through a sequence of four phases: loading, drying, cooling, and unloading. Each phase corresponds to a different configuration of the dryer.

The grain is loaded into the upper part, and once the column is filled, the fan and burner are activated to proceed with the actual drying process.

Once the drying phase is completed, the burner is turned off, and the grain is cooled before unloading. The pneumatic extractor at the base of the column manages the recirculation and discharge of the product, automatically optimizing the drying process.

The elements illustrated in the process are:

- Grain loading

- Burner intake air

- Drying zone

- Grain recirculation

- Exhaust air expulsion

- Grain discharge

- Cooling

- Emptying