- Home

- Companies

- NexGen Enviro Systems, Inc.

- Products

- NexGen Enviro - Model 122DIGIT - Medium ...

NexGen Enviro - Model 122DIGIT -Medium Volume Distillation Unit for Solvent Recycling Machine

Model: 122DIGIT. Gal Volume: 37. Dimensions: 60"L x 36"W x 65"H. Weight lbs: 748. Oil Volume Gal: 11. Watts: 13000. Power Volts: 460 3 phase. Amps: 15. Category: Medium Volume Distillation Unit.

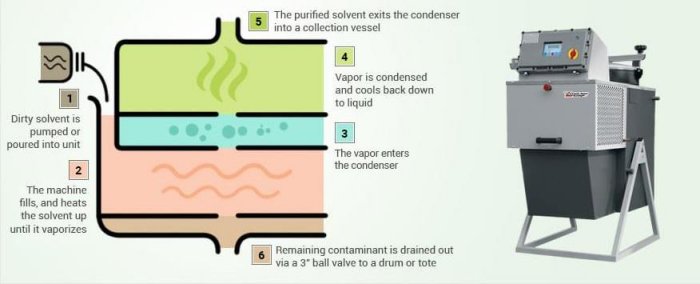

Solvent recycling equipment includes a range of machinery that separates reusable solvent from contaminants created during various production and cleaning processes. These machines work through a process of distillation, enabling solvents to be recovered in a safe and highly efficient manner, while significantly reducing your hazardous waste disposal costs.

Once dirty solvent enters into the recycling equipment, it is heated until it is vaporized. The vapor then condenses and is collected to be reused in the same manner as virgin solvent. The remaining contaminants can then be more easily disposed of and will require considerably fewer resources for handling, storage, and removal. What would have originally been solvent waste is now recycled, clean, usable, and ready to enter your process.

When manufacturers and industrial service providers make the decision to utilize solvent recycling equipment, they gain a number of advantages at multiple points in their process.

Solvent distillation equipment saves cost at the front end by reducing the amount of virgin solvent required on a regular basis. It`s possible to reclaim 90 to 95 percent of reusable solvent by implementing a solvent recycling machine that`s properly integrated into your production line.

The amount of hazardous waste created is significantly reduced requiring less storage and lowering reporting paperwork for eventual disposal. Not only does this save a considerable amount of cost for virtually any company using acetone, alcohol, and other chemical solvent, it`s simply good practice for reducing the environmental impact of essential operations.

Thanks to the versatility of solvent recycler equipment, and NexGen Enviro`s ability to modify and customize units to specific performance requirements, in-house solvent recycling is a capability that`s possible for just about any company in any industry, including: Medical, Defense, Aerospace, Agriculture, Electronics, Woodworking, Shipbuilding, Printing, Painting & Coating…and many others.

NexGen Enviro has been providing solvent recovery and recycling solutions for almost thirty years. In that time, we`ve served thousands of customers and have developed a range of equipment that accommodates many different requirements.

There are numerous features available on our solvent recyclers, large and small. It`s possible to integrate our equipment into your factory programming. We can facilitate streamlined connections into your process in a way that suits your current level of automation.

Vacuum-assisted distillation is another option. This enhancement makes it possible to lower the boiling point of the mixture and safely recover solvent that would ordinarily require higher temperatures for the recovery process. For processes that use chemical products with certain heat limitations, this option also makes it easier to recover both the solvent and the product at a lower temperature.

Many safety features are incorporated into all of our solvent recycling machinery. The PLC provides clear error codes, making it easy to identify and address any issues so that you avoid downtime. Automatic shutdown occurs when anything is amiss during processing. Controlled pressure release valves are incorporated into process tanks to prevent excess pressure build-up, which eliminates subsequent hazards. These are just a few of the redundant fail-safes we incorporate into our machinery.

All of our equipment is UL 2208 and ATEX II 2G explosion-proof listed and is built to be safe enough to operate in the average manufacturing/production facility with no special isolation or safety modifications required.

Following the initial install and programming, solvent recycling is essentially a push-button operation. There is no extensive or complicated training required for operations.

In addition to economic and environmental benefits that keep your company competitive as well as compliant, NexGen Enviro offers an exceptional level of customer service and attention to your needs.

We can help you evaluate your current process to offer suggestions on where improvements can be made. If you’ve never incorporated solvent recycling systems into your production, we can share detailed examples and demonstrations on what’s possible. We’ll even test samples of your waste solvent to show you what a difference our equipment can make.

We’ll work with you to tailor a solvent recycling unit to fit with virtually any space limitations, waste disposal processes, or special requirements of your facility.

If you’re already operating with an older piece of equipment or you think you need to upgrade to a recycling system that better suits the specifics of your operations, we’ll show you where you can improve your efficiency, output, and economy.

When solvent is required for the industrial cleanup process equipment or related parts, the resulting waste consists of a contaminated solution. This solution consists of the initial solvent, whether alcohol, acetone, or other cleaning liquid, and whatever substance was removed from the equipment, such as ink, paint, resin, grease, or oil.

Without solvent cleaning, the waste liquid must be stored until it can be properly disposed of as a hazardous material or until it can be transported to a dedicated recycling facility. Special procedures and capabilities are required for proper storage, transport, and disposal, which can be a costly part of the production process for many manufacturers. Every dollar spent on this process means fewer profits.

Having an on-site solvent recycler enables companies to reduce the costs and resources devoted to this aspect of their business. Recycling solvent in-house significantly reduces the amount of hazardous waste that requires special disposal. It also makes it easy to recover solvent for reuse, thereby reducing the amount of virgin solvent needed to be purchased.

NexGen Enviro Systems has been designing, developing and building solvent distillation and recovery solutions for nearly three decades. With over 8500 customers served across North America, we have extensive experience addressing the needs of manufacturers and service providers across numerous industries, including:

- Manufacturing

- Defense

- Aerospace

- Extraction

- Automotive

- Electronics

- Woodworking

- Shipbuilding

- Printing

- Painting & Coating

- Others

Virtually any producer of products or service provider that uses solvent at some point in their process can benefit from solvent recycling systems.

Our solvent recyclers have been designed to be the perfect combination of an off-the-shelf solution with many customizable features that can be tailored to your specific process.

Our equipment standards accommodate many different demands, and extra features can be readily adapted to a range of requirements. That means you get to essentially create a custom unit without the cost and time required to build equipment from the ground up.

Solvent recycler features can include automatic loading of waste solvent, automatic discharging of residual waste, continuous operation, vacuum assist for higher boiling solvent processing, automatic scraper blades to keep fluid in motion and aid in residual discharge, Teflon coated tanks, stainless steel condensers for highly acidic or caustic mixtures, and more. We can customize a solution to the needs of any customer.

All of our machines are UL 2208 and ATEX II 2G explosion-proof listed.

In addition to compliance with the highest safety standards in the industry, our equipment operates on a superior level of automation and allows for exceptional ease of use. That translates into substantial time and cost-saving benefits for our clients. Operation is extremely reliable and maintenance is easy, which means that you avoid downtime and reliance on additional technical labor or repairs.

We provide one-on-one guidance and careful attention to your requirements throughout the process. We`re here to ensure all of your questions and concerns are addressed before you make a purchase.

Use the contact form here on our website to tell us about your needs or call us directly. An expert member of our team can provide you with details on how a NexGen Enviro Systems solvent recycler can significantly improve your capabilities and save you time and cost.