- Home

- Companies

- Scienco/FAST - a subsidiary of ...

- Products

- Scienco-FAST - Model BioBarrier ...

Scienco-FAST - Model BioBarrier MarineMBR -Membrane Bio Reactor

We introduced the BioBarrier MarineMBR Membrane BioReactor for the marine marketplace. Just like our land-based MBR applications, this NSF/ANSI (40 class 1, 245 Nitrogen Reduction, and 350 Water Reuse), EN12566-3, USCG, and IMO, certified MBR system removes 99.9% of the contaminants from domestic and high strength wastewater flows.

To assure consistent effluent quality, the BioBarrier® MarineMBR™ (land-based version was the first system certified for water reuse (NSF/ANSI Std 350, class R) for total blackwater and greywater recycling onboard a vessel adheres to strict water quality guidelines. Each system operates automatically and is controlled by a three level float switch and timing relays in the control cabinet:

- BOD less than 5 mg/L

- TSS less than 2 mg/L

- Turbidity less than 0.2 NTU

- Fecal coliform less than 200 CFU/100 mL (without disinfection)

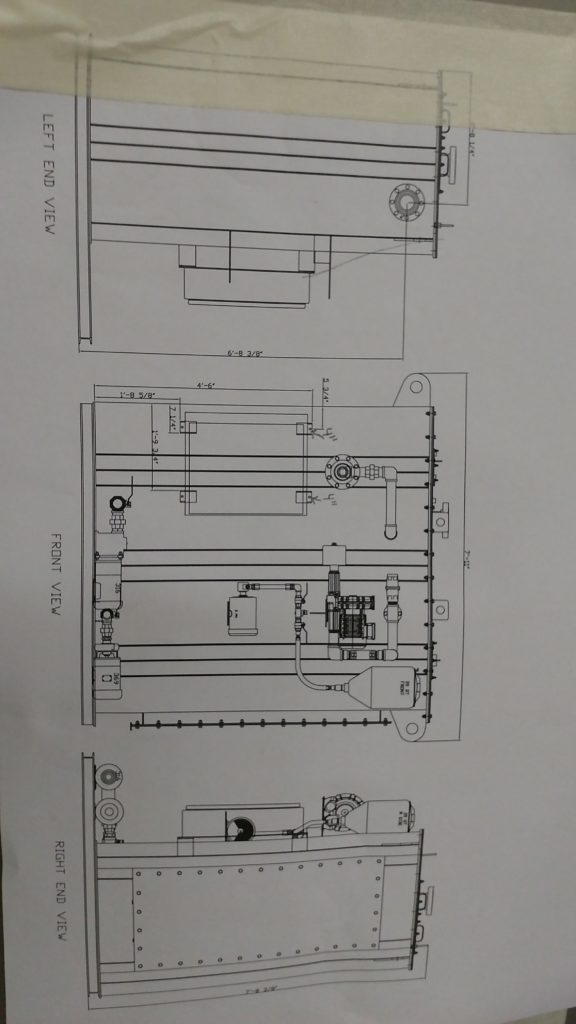

BioBarrier membrane bioreactors are engineered to treat all sources of blackwater and greywater in varying strengths and dependent on daily wastewater flow. The Scienco/FAST custom MarineMBR™ steel tank provides access for maintenance and removal of the membranes for deep cleaning or replacement. As well as the maintenance on the filtrate pumps and easy to access blower(s), while keeping as much of the equipment below deck and out of sight. All penetrations for air lines, filtrate outflow and electric cables are installed below the main deck. A submersible pump is mounted on the membrane module housing and used as the filtrate pump.

It is recommended to check what local regulations are required in case additional information is needed.

BioBarrier MarineMBR Based on GPD [L/D] and Sewage Factors

Other points of interest with this award-wining and certified membrane bioreactor technology:

- Wastewater Reuse is a hot topic and some facts to consider when planning for Wastewater Reuse.

- The big question, yet to be answered, would appear to be: Would a structure utilizing a complete wastewater reuse system, need to be connected to a septic or sewer system?

- In non-urban sites where onsite septic systems are usually installed, the building officials are reluctant to embrace this new concept.

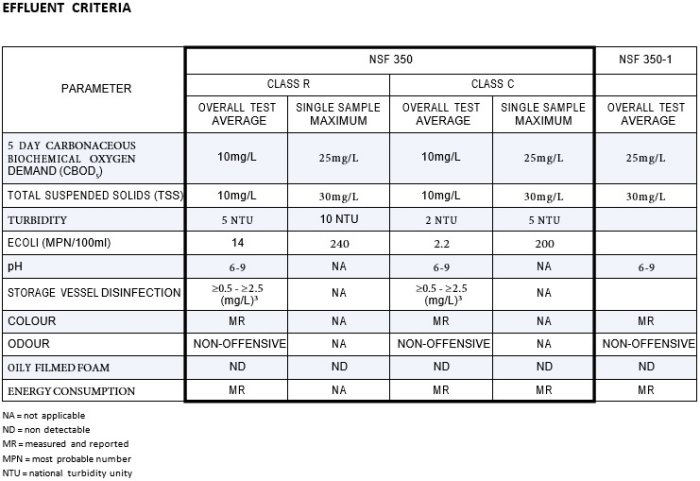

- Additional research shows that the National Sanitation Foundation (NSF) has developed new American National Standards NSF/ANSI 350 and 350-1 for “evaluating and approving water reuse treatment technologies.”

“These standards encompass both residential and commercial applications divided into those that treat all the waste- water flow from a building and those that treat the greywater portion only. While both standards are appropriate for non-potable water use, Standard 350 has more restrictive effluent quality requirements than those of Standard 350-1.”

“Both Standards 350 and 350-1 are based on 26 weeks of continuous testing with regularly scheduled sampling throughout, typically three days a week. The purpose of such a lengthy test with high volume of sampling is to assess the reliability of the product over time.” ref. Thomas Bruursema – NSF (Sustainability) International.

- In addition to the noted influent requirements, the BioMicrobics BioBarrier® MBR passes all loading sequence requirements for greywater and blackwater treatment combined and provided with a full performance evaluation report.

- The BioBarrier® MBR is listed for wastewater treatment for residential applications. It is an in ground unit which can be incorporated into new or existing septic tanks. A SaniTEE system is used to attenuate flow to improve settling and solids retention in the primary chamber. An above ground blower pumps large volumes of air into an aeration system in the secondary chamber.

- A flat sheet membrane cartridge is also located in the secondary chamber. Air bubble are vigorously forced upward through the membrane plates scouring and cleaning the membrane and providing oxygen for improved aerobic digestion.

- The flat sheet membranes have pore sizes between 0.3 – 1.3 microns using both micro and ultra filtration to block bacteria and other solids. Aeration from the bottom creates upward flow between the membranes allowing treated water to pass through for reuse.

- High quality treated water exits the onsite tank using a submersible pump and ready for water recycling initiatives, such as irrigation and machine wash-down as well as other non-potable water reuse applications.

- Opportunities for both onsite greywater, and complete wastewater recovery and reuse systems, are more significant in regions with water shortages and warmer climates.

- Those areas have a real need today and can take advantage of processed water storage tanks that can be buried or easily maintained without freezing. Opportunities for these systems are less significant in regions where water is plentiful and where the climate is colder.

- In these regions, potable water cost savings and environmental conscience will be the driving factors. The big opportunity will open up when complete wastewater recovery and reuse is viewed as the ultimate solution for onsite wastewater treatment, and a connection to the sewer system or a septic system is no longer required. Discussions on greywater reuse and complete wastewater reuse are already well underway in the United States and elsewhere.