- Home

- Companies

- Mer-Mar Electronics

- Products

- Mer-Mar - Flex PCB Prototyping Circuit ...

Mer-Mar - Flex PCB Prototyping Circuit Board

Flexible PCB prototyping is the process of manufacturing quick functional replicas of a product manufactured using substrate material that is naturally flexible. In fact, it is one of the most important technologies in use for advanced electronic products. Not without reason.

The big advantage with flexible circuit boards is of course the fact that they meet dynamic flexing requirements. In addition, flex PCB prototypes can be designed to withstand extreme temperatures. High-temperature resistance also typically comes with good chemical resistance as well as resistance to radiation and UV exposure. Some of the other advantages that flex circuit boards offer include:

- They are lightweight and thin and therefore lend themselves to miniaturization.

- As their name suggests, they offer flexibility and hence more freedom to decrease the mechanical footprint.

- Flex PCB prototypes are resistant to high temperature, oils, gases and acids.

- Flex PCB prototyping is highly durable. The reduced number of interconnects allow them to handle changing forces and improve their resistance to shock.

- They have high signal integrity.

- They can support high circuit densities.

- They lend themselves to reduced wiring errors.

- On account of fewer assembly steps involved, they tend to be relatively low-cost

- They offer improved heat dissipation.

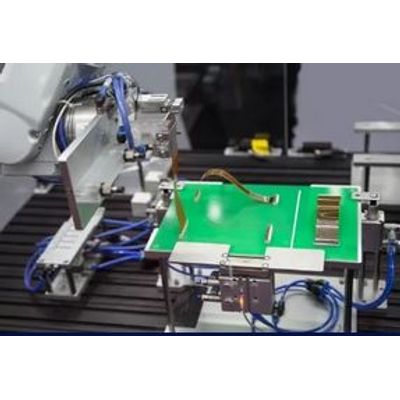

As a leading prototype to production flex PCB manufacturer, at Mer-Mar Electronics we offer high quality flex PCB prototyping services to suit your bespoke requirements. In addition, we offer quick turn flex PCB Prototype services that makes go-to-market that much easier. A large portfolio of satisfied clients stand testimony not just to our design and prototype to full production run manufacturing capacity, but also to our technical and engineering capabilities. Our state-of-the-art equipment as well as superior technical expertise ensure that getting early functional replicas of your products was never so easy. You can easily test and ratify your product’s functional design. In addition, our PCB prototypes help reduce the overall project cost as any issues are found in the early stages of the cycle.

Superior facility – Our state-of-the-art manufacturing equipment as well as our technical expertise enable us to produce high quality flex PCB prototypes that are significantly ahead of the curve. You can count on our experienced staff that is armed with industry best practices. What that means is that you do not have to reinvent the wheel.

Adherence to strict industry standards – When it comes to PCBs, you cannot afford to take any chances. We ensure strict adherence to leading industry standards. Besides we have robust testing procedures that ensure you are covered.

Quick turn around time – Our quick turnaround times ensure that your go-to-market time is significantly reduced and your competitive advantage, heightened.

Easy to scale up – The big advantage of partnering with us is not just that we offer you prototype quantities with an eye for detail. It is also that we offer you scalability. So, when you need to order a full production run, we have you covered as well.

Stringent tests on components – With complex projects, we ensure there is individual testing of each component to identify flaws, if any. In turn it leads to necessary replacements and ensuring viability of the PCB.

Flex PCB Prototyping Services

Flex PCB Prototype Design

Count on us to offer you initial efficient flex PCB designs that work well for your miniaturized product. In addition, we offer robust design for manufacturability tests. This ensures that you do not have to deal with delays or costly errors when it is time to move to the full production stage.

Additive Manufacturing

With our additive manufacturing systems and processes, we can craft the most complex multilayer PCBs with ease. These prototypes come with high component density and miniaturization.

Single-sided, dual-access and sculptured flex circuits

We offer single-sided flexible circuits which have a single conductor layer made of copper on a flexible polyimide material. You could also opt for dual access flex circuits where access to selected features is available from both sides. Sculptured flex circuits are a subset of normal flexible circuits that are manufactured through a multistep etching method.

Flexible PCB Turnkey Services

We offer full turnkey prototype services. Bank on us for part procurement at the most cost-effective rates and efficient assembly. In turn, what this offers to you is the ability to focus on your core competencies.

PCB Prototyping and Production flexibility

With our on-demand services, you do not have to commit to any volume requirements. Simply state your requirement and have the most high-quality flex PCBs made available to you.