Dongguan Vnovo New Material Technology Co., Ltd.

- Home

- Companies

- Dongguan Vnovo New Material Technology ...

- Products

- Vnovo - Model T - Metal Gear Grease

Vnovo - Model T -Metal Gear Grease

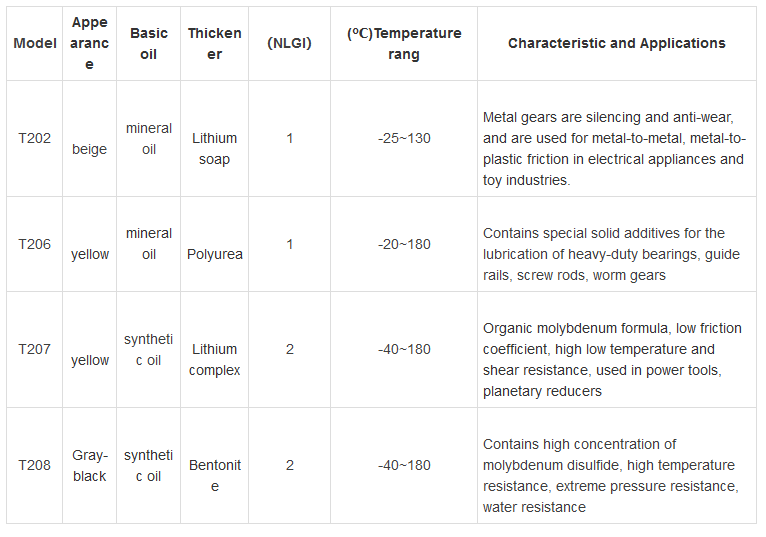

In the metal pinion transmission mechanism, these metal pinion transmission pairs have different requirements for grease due to different materials, different sizes, different speeds, different gear shapes, different precision and many other factors.There are several criteria to consider when selecting the metal gear grease:

Most popular related searches

- Wear resistance, low friction coefficient, prevent gear surface wear, ensure high efficiency and long life of gears

- Good adhesion.Due to the grease rejection caused by the centrifugal force generated by the high-speed rotation of the gear, the grease must have good adhesion to the metal, and can form a high-adhesion oil film on the gear tooth surface, while effectively suppressing noise.

- Good mechanical stability. When the gear is running, the grease will be sheared, which will cause the mechanical disintegration of the soap dispenser structure of the grease, and the grease will become soft and thin and will be lost, resulting in no oil film on the tooth surface. generating noise, and temperature rise, thus losing the lubricating effect;

- Select temperature base oil and thickener according to the requirements of the operating environment.Fully synthetic base oil can reduce starting and running torque in cold environments without affecting motor temperature rise and current;Choosing the high dropping point thickeners.such as polyurea. lithium complex, can better meet the high temperature resistance requirements of metal gears.

- Excellent compatibility: anti-corrosion, anti-rust effect, good compatibility with most of metals, plastics and rubber and contacting media.