Wm. W. Meyer & Sons, Inc.

- Home

- Companies

- Wm. W. Meyer & Sons, Inc.

- Products

- Meyer - Model HDX - Heavy Duty Rotary ...

Meyer - Model HDX -Heavy Duty Rotary Airlock Valve

The HDX Heavy Duty Extra-Tough Drop-Thru rotary airlock valves are designed to withstand high temperatures and pressure differentials up to 22 psi. This legendary design sets the standard by which all others in the industry are measured. It offers the heaviest gauge rotor vane stock of any competing product, extra thick endplates, flanges and housing walls, along with outboard mounted oversized bearings that are prelubricated and permanently sealed to ensure low maintenance and prolonged life.

Most popular related searches

rotary airlock valve

rotary airlock

airlock valve

airlock rotary valve

rotary valve

rotary airlock feeder

pneumatic conveyor

heavy-duty rotary valve

tungsten carbide

mounted bearing

- Heaviest gauge rotor vane stock

- Extra thick endplates, flanges and housing walls

- Outboard mounted oversized bearings, prelubricated and permanently sealed

To minimize costly maintenance and down-time, the Meyer PRO-TEC Seal is an enhanced Inflated Shaft Seal specifically designed for use in very abrasive, positive pressure pneumatic conveying applications.

The HDX is available with:

- 6-vane or 8-vane rotor design

- Square or round flange housing with:

- Cast iron

- 304/316 stainless steel, or

- Ni-hard construction

- Pressure Rating: 22 PSI

- Maximum Operating Temperature: 1,000°F

- Materials: Dry Free-Flowing Including: Corrosive, Hygroscopic, Abrasive

- Our rotary airlock valves are used in a wide range of applications where there is need to minimize system air loss while transferring material between vessels with differing pressures.

- They are used as feeder valves to meter the flow of material between vessels with equivalent pressures.

- You will also find them doing double duty in systems where there is a need to minimize system air or gas loss while regulating the flow of material between vessels with differing pressures.

- Pneumatic Conveying, Blending, Dust Collection, Drying, Pollution Control, Weighing, Mixing, Feeding.

- Asphalt, Cement, Food, Power, Baking, Mining, Chemical, Paint, Plastics, Petrochemical.

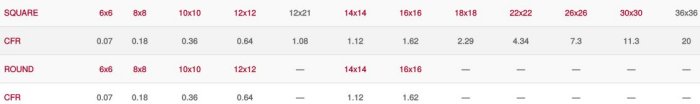

- Available in fourteen sizes from 4×4 through 36×36

- Round or square flange assures system compatibility

- Larger diameter shafts for less deflection and optimum torque deliver

- Permanently sealed bearings ensure protection from contamination

- Special rotor designs including coatings, polishing, shallow pockets and closed end to specifically match your application

- Cast iron or stainless steel housings are standard providing maximum structural stability with optional cast materials available including; inconel, hastelloy, cast steel or aluminum

- Housing coating options include hard chrome, nickel, Teflon, tungsten carbide, chrome carbide and plasma