- Home

- Companies

- Compressed Gas Technologies Inc.

- Products

- MIDIGAS - Nitrogen Gas Generators - ...

MIDIGAS - Nitrogen Gas Generators - Pressure Swing Adsorption (PSA)

Compressed Gas Technologies Inc. MIDIGAS PSA (Pressure Swing MIDIGAS Nitrogen Gas Generators Adsorption) nitrogen generators are designed for low flow applications that require high purity nitrogen (>99.5%). Nitrogen is used as a clean, dry, inert gas primarily for removing oxygen from products and/or processes. MIDIGAS nitrogen gas generators provide an on-demand, continuous source of nitrogen gas. Continuous nitrogen as sources can be used in a wide range of industries such as food, beverage, pharmaceutical, laboratory, chemical, heat treatment, electronics, transportation, oil and gas and laser cutting. MIDIGAS nitrogen gas generators produce nitrogen gas from compressed air and offer a cost-effective, reliable and safe alternative to traditional nitrogen gas supplies such as cylinder or liquid.

MIDIGAS operates via the pressure swing adsorption (PSA) principle to produce a continuous stream of nitrogen gas from compressed air. Pressure swing adsorption processes rely on the fact that under pressure, gases tend to be attracted to solid surfaces, or "adsorbed". The higher the pressure, the more gas is adsorbed; when the pressure is reduced, the gas is released, or desorbed. PSA processes can be used to separate gases in a mixture because different gases tend to be attracted to different solid surfaces more or less strongly. If a gas mixture such as air, for example, is passed under pressure through a vessel containing an adsorbent bed that attracts nitrogen more strongly than it does oxygen. Part or all of the nitrogen will stay in the bed, and the gas coming out of the vessel will be enriched in oxygen. When the bed reaches the end of its capacity to adsorb nitrogen, it can be regenerated by reducing the pressure. Thereby releasing the adsorbed nitrogen. It is then ready for another cycle of producing oxygen enriched air.

Pairs of extruded aluminum columns are filled with carbon molecular sieve (CMS). Pre-treated compressed air enters the bottom of the online column and flows up through the CMS. Oxygen and other trace gases are preferentially adsorbed by the CMS, allowing nitrogen to pass through. After a pre-set time, the on-line column automatically switches to regenerative mode, venting contaminants from the CMS. Carbon molecular sieve differs from ordinary activated carbons as it has a much narrower range of pore openings. This allows small molecules such as oxygen to penetrate the pores and separate from nitrogen molecules which are too large to enter the CMS. The larger nitrogen molecules by-pass the CMS and emerge as the product gas.

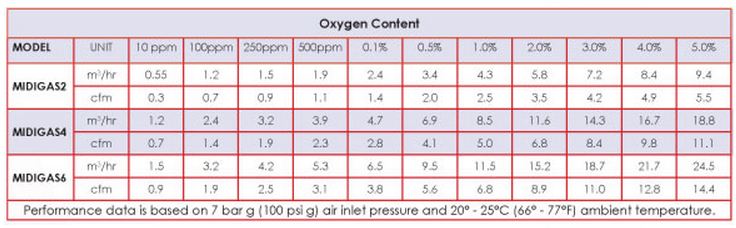

- Nitrogen flows from 0.3 scfm to 14.4 scfm

- Nitrogen purity adjustable from 95% to 99.999%

- High efficiency compressed air pre-treatment package

- Oxygen analyzer with alarm capabilities

- Flow meter

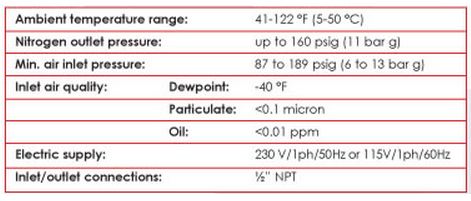

- High pressure capabilities - up to 160 psig outlet

- Compact space saving design

- Flexible modular design

- High efficiency CMS

- Service due indicators

- ECO Mode - energy saving during low demand

- Oxygen analyzer for continuous monitoring of nitrogen purity

- Flow verification kit

- Analog outputs for remote monitoring

- Alarm connections

- Noise reduction