CRS NI LTD

- Home

- Companies

- CRS NI LTD

- Products

- CRS - Model CRS-038 - Mobile Tracked ...

CRS - Model CRS-038 -Mobile Tracked Screen

FromCRS NI LTD

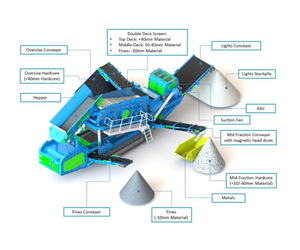

The CRS-038 Mobile Tracked Screen, the next evolution in CRS Mobile Screening Plant, combines our state of the art flip flow screening technology and conventional scalping screen to produce a single machine that does the work of two.

The Mobile Tracked Screen can perform the processing and separation tasks that previously would have required two separate machines. The CRS-038 Mobile Fines results in substantial savings for the customer in terms or capital outlay, running and service costs. It also requires a minimal footprint for operation making it suitable for the typical confined sites in towns and cities.Most popular related searches

track screen

flip flow screen

mobile screen

scalping screens

mobile screening plant

stockpile conveyor

belt feeder

air separator

screening system

screening plant

- Efficient drive system coupled with unique screen deck design ensuring maximum agitation

- High screening efficiency

- 4 Splits plus metals

- Magnetic head drum on mid fraction material for metals recovery

- Fully adjustable belt and screen speeds coupled

- 14No Vulkalon screen mats. Clip fasteners for easy maintenance

- 5m screen width x 4.7m screen length

- Easily manoeuvred from site to site with quick set up time

- Eliminate screen binding, plugging and blockages

- Ability to handle a diverse range of materials

- Minimal Footprint suitable for confined sites

- Combination of scalping screen & flip flow removes the need for 2 machines

- Top screen deck can be a 3D screening type, finger bar type or conventional punch plate depending on screening material

- Air separation unit separates the light and heavy fractions

- Suction fan on Mid fraction stockpiling conveyor to remove any light particles

- Power pack to run tracks, Screenbox and folding operations on conveyors

Belt Feeder & Hooper:

- Belt feeder & hopper 3.2 cubic metres – 1000mm (39”) wide chevron belt – 3500mm drum crs (11’-6”)

- 3.0kW Motor (c/w variable speed) & Gearbox unit (High torque, low speed)

Screening Decks:

- Top deck – 5000mm (16′-5″) x 1500mm (5′) Scalping Screen – variable speed control.

- Top deck screening options – Punch plate, Tines, 3D mesh screen

- Bottom deck – Flip flow screen – 5000mm (16′-5″) x 1500mm (5′) screening area – various apertures available

- Flip flow mats – Wedge fasteners for quick turnaround time on changing of screen mats

- Hydraulic Motor

ASU:

- Air separation drum – variable speed and hydraulically adjusted

- 75kW Motor (c/w variable speed) & Gearbox for ASU drum rotating

- Fan 11kW (c/w variable speed) & manually adjustable nozzle

Conveyors:

- Fines collection conveyor – 1400mm (55″) wide 3ply plain belt – 5000mm (16′-5″) drum crs – 3kW Motor & Gearbox

- Mid product conveyor – 600mm (24″) wide 3 ply chevron belt – 6000mm (19-‘8″) drum crs c/w Magnetic head drum. Hydraulically folded – 3kW Motor & Gearbox. Suction Fan on mid product conveyor – 7.5kW

- Fines stockpiler conveyor – 600mm [24″] wide 3 ply chevron belt- 6000mm (19- ‘8″) drum crs c/w Magnetic head drum. Hydraulically folded – 3kW Motor & Gearbox

- Lights conveyor – 1800mm (70″) wide 3ply belt – 5800mm (19′) crs – Hydraulically folded – 3.0kW Motor & Gearbox

- Oversize product conveyor -900mm (36″) wide 3ply belt – 5500mm (18′) drum crs– Hydraulically folded – 3kW Motor & Gearbox

Tracks:

- 400mm (16″) pad width

- 4000mm (13′-1″) drum crs

- Dual speed motors on tracks

Total running kW’s = 75kW

- Can be run on mains power or diesel generator

- GeneratorFPT IVECO 107Kw

- 4-Stroke Diesel

- Liquid Cooled

- Typical Elec. Output Prime 107kW Prime

- Typical Elec. Output Stand-by 118 kW Standby

- Electrical Frequency : 50Hz/1500rpm