- Home

- Companies

- H2O Innovation

- Products

- Model Bio-Wheel™ - Advanced High ...

Model Bio-Wheel™ -Advanced High Efficiency Wastewater Treatment System

The Bio-Wheel biological treatment system has been developed to combine the compactness and flexibility of the activated sludge process with the stability and sinplicity of the fixed film process. The Bio-Wheel system integrates the two processes in a single tank by using a simple mechanical drive system. The rotation of the Bio-Wheel provides alternating air and water cycles for the fixed film process, and aeration and mixing for the activated sludge process.

With the Bio-Wheel system, advanced water treatment with high quality effluent is possible by biodegradation of the organic compounds, nitrification, and denitrification and uptake of excess P without using chemicals.

High Process Efficiency

By combining activated sludge and fixed film processes into a single system, a much higher treatment efficiency is obtained.

Sturdy and Simple Construction

Bio-Wheel wheels are assembled at the construction site from sub-assemblies prepared at the factory. Through modular construction, it is possible to provide wheels of many different sizes to suit any given application.

Reliability of Operation

A high degree of flexibility and stability in the treatment process is possible due to the wide spectrum of fixed and suspended microorganisms combined with the ability to regulate oxygen intake. Temporary overloads can be buffered without problem.

Reduced Need for Space, Lower Cost to Build

High operating efficiency and compact design reduce space requirements as much as 40% over comparable systems. There is no yard piping, yard electrical or buildings to house equipment. Cost of construction is reduced due to the small size and simplicity of the system.

Reduced Power Consumption and Operating Cost

Power consumption of the Bio-Wheel is less than 30% of other aerobic processes using blowers.

Advanced Wastewater Treatment

With the Bio-Wheel process, it is possible to achieve nitrification and denitrification, bringing BOD5, TSS and N Total substantially below 10 mg/L, and reducing P to 1.0 mg/L or less.

No Annoying Odors, Low Noise Level

Through efficient oxygen transfer, air intake requirement is minimized. Most of the turbulence and mixing take place within the submerged aerator, minimizing the production of aerosols and emission of odors. There are no blowers requiring dust control, silencers, or protective covers.

Simple Control System

Sophisticated microprocessor controls are not required. Electrical panels are straight forward based on position switches and annunciator lights.

Optimum Consistency of the Sludge

The sludge settles well and has excellent dewatering characteristics due to the fixed film component of the system. The clarifier and sludge treatment facilities can be designed with less volume and be more compact. Waste sludge is greatly reduced in volume.

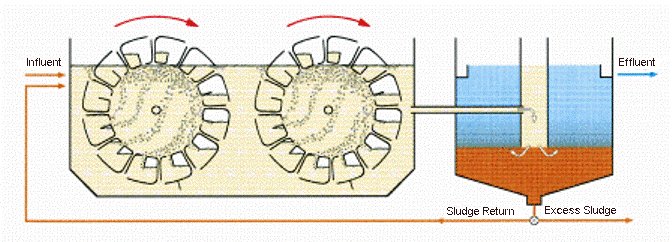

In general the following process steps are involved:

- Mechanical pretreatment with a bar screen, comminutor or pre-clarification.

- Aeration and mixing in the bio-tank with the rotating Bio-Wheel.

- Clarification, with sludge recycling to the bio-tank and withdrawal of excess sludge.

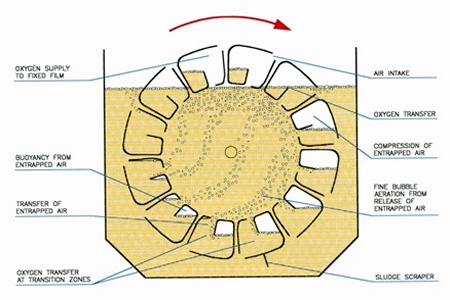

The heart of the wastewater treatment process is the Bio-Wheel which consists of a rotating structure with patented cell plates arranged in a series of rows. The cell plates are 3/4" apart and provide a roughened surface as media for fixed film growth, and also provide a source of aeration for the activated sludge. By adjusting the speed of rotation for varying oxygen requirements, treatment of the wastewater occurs both in the activated sludge and the fixed film.

During rotation of the Bio-Wheel, trapped air is gradually released into the mixed liquor as fine bubble aeration. Some of the air is transferred from one pocket to another inside the cells providing additional buoyancy reducing energy requirements. Before the cells are rotated to the surface, all air is expended as fine bubble diffusion. By this method, the time of retention of air-water contact is extended so that oxygen transfer is optimized.

The rotational speed of the Bio-Wheel is adjustable, which regulates the amount of aeration and mixing in the bio-tank. The deep submergence of the wheel in the mixed liquor increases the efficiency of oxygen transfer.

The Bio-Wheel consists of a number of cells, which are arranged in a circular fashion around a horizontal shaft as shown in the schematic drawing. Each cell contains a number of specially profiled polypropylene plates which form a self supporting segment to provide aeration and mixing as well as a surface area for the biologically active fixed film. The wheel is submersed to 80% of its diameter in the mixed liquor and is driven by an easily accessible gear motor and chain drive located above the liquid level on the upper wall of the bio-tank.

Aeration and mixing are provided by the rotation of the Bio-Wheel. As a cell emerges above the mixed liquor, the liquid drains out, and the cell is filled with air under normal atmospheric pressure. Because the large surface of the plate is directly exposed to pressure of the air, immediate saturation of oxygen is obtained.

As the Bio-Wheel rotates and the cell segments are submerged into the mixed liquor, the entrapped air is compressed and forced toward the bottom of the bio-tank. During downward rotation, a portion of the air escapes to the surface as fine bubbles. The resulting turbulence, combined with the rotation of the wheel, provides homogeneous mixing in the bio-tank. During upward rotation of the wheel, the partially air filled cell provides buoyancy and reduces the power required for rotation.

The fixed film on the surface area within the cells is supplied with oxygen while above the surface, and air is taken in to be compressed and distributed during rotation. This process results in the coincident supply of oxygen for the fixed film and the activated sludge.

The intake of air is adjusted by the speed of rotation of the Bio-Wheel. Even with very high loading and corresponding high oxygen consumption rates, a sufficient supply of oxygen can be transferred. The fixed film component provides an ideal environment for slow growing nitrifiers to provide stable nitrification. By creating a separate anoxic zone, complete nitrification and denitrification can be provided with minimal power consumption by the Bio-Wheel system.

The properties of the Bio-Wheel system are the high degradation efficiency, high quality effluent and high degree of flexibility.

New plants can be constructed in concrete tanks, or steel packaged systems can be furnished. There are a large number of standard sizes of wheels available, and special sizes can be constructed. Existing plants can be retrofitted with the Bio-Wheel system to upgrade capacity and effluent water quality, while lowering operating cost.

The materials used in construction guarantee a long service life with low maintenance. The steel frames of the wheels are galvanized, and the cell plates are of UV resistant polypropylene. Stainless steel fastenings are used, along with UHMW nylon and stainless steel bearings. Inverted "A-frames" are used to suspend the Bio-Wheel from the top of the concrete or steel tank, so that the entire wheel may be easily removed for maintenance or inspection without dewatering the bio-tank.

- Applications include the following:

- Treatment of domestic and municipal wastewater from 2,000 GPD to 2 MGD.

- Treatment of domestic wastewater containing industrial and manufacturing wastes.

- Treatment and pre-treatment of high strength organic industrial wastewater.

- Treatment of land fill leachate.

- Combined with septic tanks and lagoons for improved nitrification, denitrification and biological phosphorus removal.

- Food processing operations.

- Aerobic sludge stabilization