- Home

- Companies

- Shanghai Rongde Mechanical and ...

- Products

- Model Bubble Type - Liquid Level ...

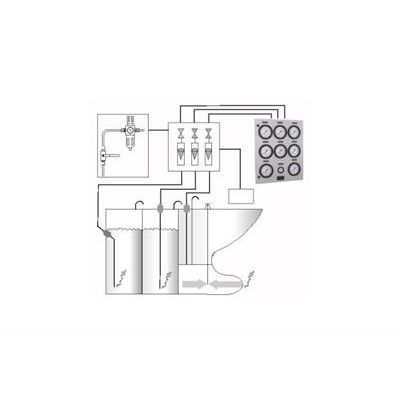

Model Bubble Type -Liquid Level Measuring Device

Based on the principle of hydrostatic measurement, if there is continuous air entering the detector at the bottom of the cargo tank (commonly referred to as the sounding tube), when a small amount of air overflows from the discharge at the bottom of the cargo tank, a liquid is associated with The pressure at the level will be established in the sounding tube.

Based on the principle of hydrostatic measurement, if there is continuous air entering the detector at the bottom of the cargo tank (commonly referred to as the sounding tube), when a small amount of air overflows from the discharge at the bottom of the cargo tank, a liquid is associated with The pressure at the level will be established in the sounding tube. If the density of the liquid is known and the pressure in the sounding tube has been detected, we can calculate the distance between the opening of the sounding tube and the liquid level. This value can be displayed in the table in the form of depth, volume or percentage of cargo tank.

- Range: 0 to 6 m, 0 to 10 m, 0 to 25 m

- Measurement accuracy: ±1.5% FS

- Measurement dead zone: 100 mm

- Air supply pressure: 0.6 to 0.7 MPa

- Working pressure: 0.3 MPa

- Gas consumption: 10L/h per measuring point

- Working environment temperature: -25°C~+60°C

- Control box installation method: wall-mounted type

- Sounding tube: Φ6×1, Φ8×1, Φ10×1.5

- With high and low level and high limit low level alarm function, it can automatically emit audible and visual alarm signal.

- Pressure transmitters have IP56, Ip68 enclosures to meet the needs of different locations.

- With the measured medium specific gravity correction function

- With RS485 serial communication interface

- RDLY type pressure sensor with high measurement accuracy, and obtained CCS, CMC certificate

- With internal fault and sensor fault self-test function