- Home

- Companies

- Pneumat Systems, Inc.

- Products

- Model Cardox CO2 Blaster - A Reusable ...

Model Cardox CO2 Blaster -A Reusable Gas Expansion System

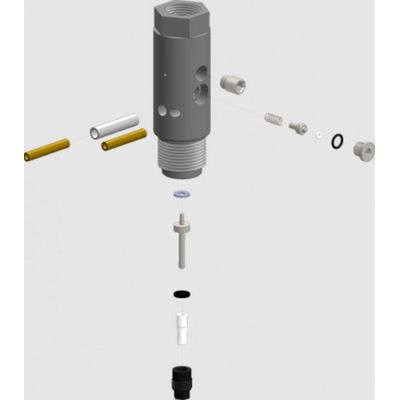

The Cardox CO2 Blasting system consists of a reusable metal tube that is secured into a vessel or directly into the material to be blasted.

Inside the high-strength steel alloy tube is a charge of liquid carbon dioxide and a chemical energizer. When remotely initiated by a small electric charge, the carbon dioxide inside the tube rapidly expands. At around 34,000 psi the pressure bursts a rupture disc and is released through the ports on the discharge head as high-velocity jets of inert gas with the power to dislodge and break up tons of material. The process occurs in less than one second – with no risk of igniting combustible materials or gasses in the vicinity.

Pneumat has led the development of Cardox technology for decades and is home to the nation`s leading Cardox experts. We are the inventors of the Rapid-Fill Pump and Auto-Fill Head that revolutionized how Cardox tubes are filled, eliminating the need to keep tubes refrigerated at the worksite.

The primary advantage of the Pneumat Cardox CO2 Blasting System over competing products is the extent to which our field technicians, engineers, and machinists have collaborated to produce a system that essentially eliminates misfires. Misfires are a frustrating scenario that results in downtime, threatens worker safety, and increases operational costs.

If half your blasting attempts result in misfires, you are effectively paying twice as much for consumables. Choosing a precision-engineered Pneumat Cardox system maximizes the value of your investment for years to come.

Cardox blasts are often performed inside of a vessel with limited visibility. This demonstration pushing around a huge boulder shows just how much force Cardox can generate by instantaneously converting a small amount of carbon dioxide from liquid to gas.

Cardox equips your team with a safer alternative to traditional explosives.