SPXFLOW

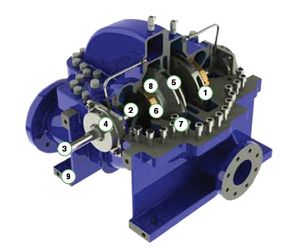

Model Duoglide-e -Single and Two Stage Pump

FromSPXFLOW

The ClydeUnion Pumps Duoglide-e range is the latest generation of axial split two stage pumps. The range has been developed using the latest 3D and FEA analysis software together with extensive consultation of major users. This has produced an advanced pump which will provide total reliability and reduced whole life costs

Most popular related searches

axial split case

split case

axially split pump

vertical pump

corrosion protection

water treatment

drinking water

axial pump

water desalination treatment

desalination treatment

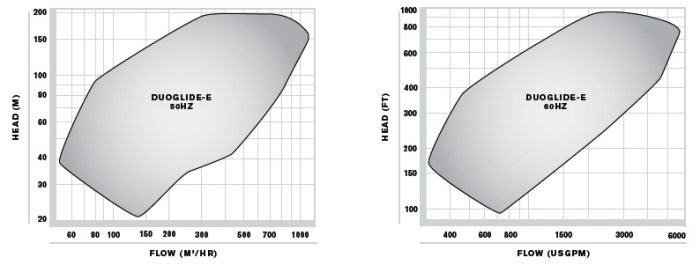

- Capacity: up to 1,350 m3/hr / 5,950 gpm

- Delivery head: up to 275 m / 910 feet

- Temperature: up to 80 oC / 180 oF

- Speeds: up to 1,800 rpm

- Flange drilling: BS or ANSI

- Desalination

- Water treatment, supply and distribution

- District heating and district cooling

- Power auxiliaries

- Mining

- Metal manufacturing

- Chemical and petrochemical industries

- General industrial applications

- Building services

The ClydeUnion Pumps Duoglide-e range is the latest generation of axial split two stage pumps. The range has been developed using the latest 3D and FEA analysis software together with extensive consultation of major users. This has produced an advanced pump which will provide total reliability and reduced whole life costs:

- 14 individual pump frames sizes divided into 4 modular shaft groupings

- Horizontal and vertical configurations available

- Standard cartridge bearing and seal assemblies facilitate easy maintenance

- Material options available for non-corrosive and corrosive applications including seawater

- Bearing configuration automatically selected to match specific pump duty

- WRAS and NSF coatings suitable for potable water available

- Designed for both 50Hz and 60Hz markets

- Clockwise and anti-clockwise rotation available

- Low energy costs

- Hydraulic design provides low NPSH, stable characteristics and high efficiency further enhanced with internal coating on cast iron casings and polished internals for steel alloy applications

- Improved seal reliability

- Unique adaptor design allows fitment of all major suppliers cartridge seal assemblies

- Extended shaft life

- Shaft designed to minimise dynamic shaft deflection and provide ample safety factor in rotation speed, ensuring an extended shaft life

- Ease of maintenance

- Split casing design simplifies maintenance by allowing access to pump rotor without disturbing pipe work or driver. Additionally cartridge bearings and seals can be changed in a fraction of the time taken on a conventional axially split case product

- Increased component life

- Stainless steel impellers as standard , and steel alloy impellers for selected applications, offer superior corrosion protection and optimum lifetime operation. Absence of impeller key eliminates the potential for fretting and fatigue failures. All spare impellers are mounted on a new shaft as standard

- Wear options

- For economical renewal of operational clearances, replaceable metallic wear rings are fitted as standard, which reduces pressure leakage and improves the overall efficiency. Composite wear rings are available as a standard option

- Double volute casing design

- Radial thrust reduced by utilising double volute casing design on all but smallest frames offering improved efficiency, minimised vibration and extended seal and bearing life

- Single entry impellers

- Back to back single entry hydraulically balanced impellers designed with optimised geometry provides high efficiency and low NPSH whilst minimising axial thrust for extended bearing and seal life

- Horizontal / vertical arrangement

- Rigid integrally cast feet allows mounting arrangement to be horizontal or vertical. Vertical pumps are fitted with a product lubricated bottom bearing as standard