SPXFLOW

Model Duoglide -Single and Two Stage Pump

FromSPXFLOW

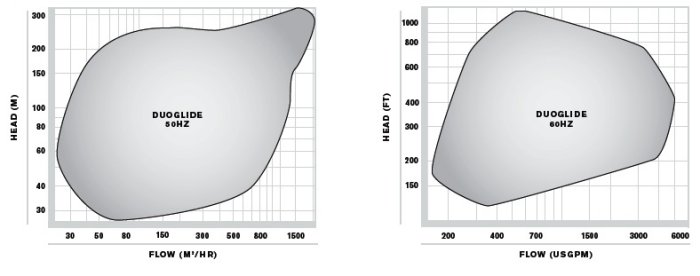

The ClydeUnion Pumps Duoglide range consists of both configured and engineered to order axially split case, two stage pumps designed for higher head/flow applications. The Duoglide provides higher efficiency and lower maintenance than traditional ring section or high speed single stage pumps.

Most popular related searches

axial split case

axial split case pump

split case

split case pump

vertical pump

water treatment

drinking water

axially split pump

water desalination treatment

desalination treatment

- Capacity: up to 2,500 m3/hr / 11,000 gpm

- Delivery head: up to 320 m / 1,050 feet

- Temperature: up to 80 oC / 180 oF

- Speeds: up to 3,600 rpm

- Flange drilling: BS or ANSI

- Desalination

- Water treatment, supply and distribution

- District heating and district cooling

- Power auxiliaries

- Mining

- Metal manufacturing

- Chemical and petrochemical industries

- General industrial applications

- Building services

The ClydeUnion Pumps Duoglide range consists of both configured and engineered to order axially split case, two-stage pumps designed for higher head/flow applications. The Duoglide provides higher efficiency and lower maintenance than traditional ring section or high speed single stage pumps:

- Extensive range to cover all duties at optimal efficiency

- Horizontal and vertical configurations available

- Various sealing arrangements available

- Material options available for non-corrosive and corrosive applications including seawater

- Radial and thrust bearings available with either grease or oil lubrication

- WRAS and NSF coatings suitable for potable water available

- Designed for both 50Hz and 60Hz markets

- Clockwise and anti-clockwise rotation available

- Low energy costs

- Hydraulic design provides low NPSH, stable characteristics and high efficiency further enhanced with internal coating on cast iron casings and polished internals for steel alloy applications

- Sealing arrangement

- Single, double and cartridge options. Packed gland option available on request

- Ease of maintenance

- Split casing design simplifies maintenance by allowing access to pump rotor without disturbing pipe work or driver

- Extended shaft life

- Shaft designed to minimise dynamic shaft deflection and provide ample safety factor in rotation speed, ensuring an extended shaft life

- Shaft sleeves

- Renewable shaft sleeves are available in a variety of materials offering shaft protection against stuffing box wear

- Wear options

- For economical renewal of operational clearances, replaceable metallic wear rings are fitted as standard, which reduces pressure leakage and improves the overall efficiency. Impeller and composite wear rings are available as a standard option

- Casing design

- Robust casing designed to reduce external forces and vibration incorporating integral bearing support. Double volute design utilised on appropriate frames

- Single entry impeller

- Back to back single entry hydraulically balanced impellers designed with optimised geometry provides high efficiency and low NPSH whilst minimising axial thrust for extended bearing and seal life

- Horizontal / vertical arrangement

- Rigid integrally cast feet allows mounting arrangement to be horizontal or vertical. Vertical pumps are fitted with a product lubricated bottom bearing as standard