Model GRP -Glass Fiber Reinforced Plastic Pipe

Continuous filament-fiber winding production process and technology are used. NOMINAL DIAMETERS: 300mm-2800mm. PIPE LENGTH : As standard 6 m-12 m. It is produced in desired lengths between 1 m and 15 m in lengths allowed by highways. PRESSURE CLASS: PN 1 bar-PN-40 bar. REGULATORY CLASS: SN 2500 N / m2, SN 5000 N / m2, SN 10,000 N / m2 standard is produced, according to the needs of the project is produced in the desired rigidity classes.

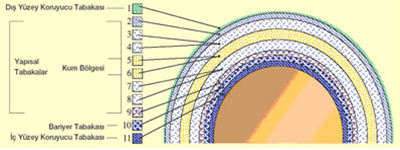

GRP pipes consist of three layers supporting each other. Each floor has its own characteristics and function. The structure of these three layers is water.

Inner Layer:

It is the inner layer of the pipe which directly contacts the material it carries. Resistant to all chemicals in the liquid it carries, its maximum resistance is increased.

Middle Layer:

It is the layer that provides the resistance of the pipe against internal and external pressures and loads. The thickness of the inner layer is made in a thickness that can resist the internal and external loads to be carried by the pipe. Glass fiber wick and clipping resin and sand are used in this layer.

Outer Layer:

It is manufactured using at least 2 mm thick resin and glass fiber to protect the pipe against external influences. Additional additive material can be used if necessary to protect against sunlight.

- Connection of the pipes to each other, the sleeves produced by cutting GRP pipes and opening the roving slot in diamond-tipped machines are used. Rubber seals are inserted into the slots opened into the sleeves to prevent leakage.

- Fasteners and Special Parts A

- wide variety of fasteners used in network connections are also produced by cutting GRP pipes in various shapes and manufacturing them by hand-laying method using glass fiber cloth felt and resin as garments. Used in molds when necessary.

- It is possible to produce a wide range of fasteners according to the project and customer requirements.

AREA OF USAGE

- Drinking water network and transmission lines

- Irrigation networks and drainage applications

- Sewerage projects network, collector lines

- Sewerage projects elevation lines

- hydropower plant penstock applications

- rainwater drainage

- supply cooling water in power stations and discharge

- chemical content of transporting fluids

- renovation of old pipelines (Re- Lining)

- removal of industrial waste

- Handling of geothermal waters

- Chemical plants and drinking water reservoirs

- marine outfall applications

- PRIME RAW MATERIALS

- Isophthalic, orthophthalic polyester resins, E / ECR glass fibers, quartz sand etc. raw materials.